Plane material otter board stuffing type cross flow type hypergravity swinging bed and uses thereof

A high-gravity rotating bed, packed technology, applied in the direction of using liquid separation agent, dispersed particle separation, fractionation, etc., can solve the problem of limiting the surface area of the high-gravity rotating bed droplet heat transfer, mass transfer and dust removal efficiency, etc., to achieve open Large porosity, high-efficiency trapping, and enhanced mass and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

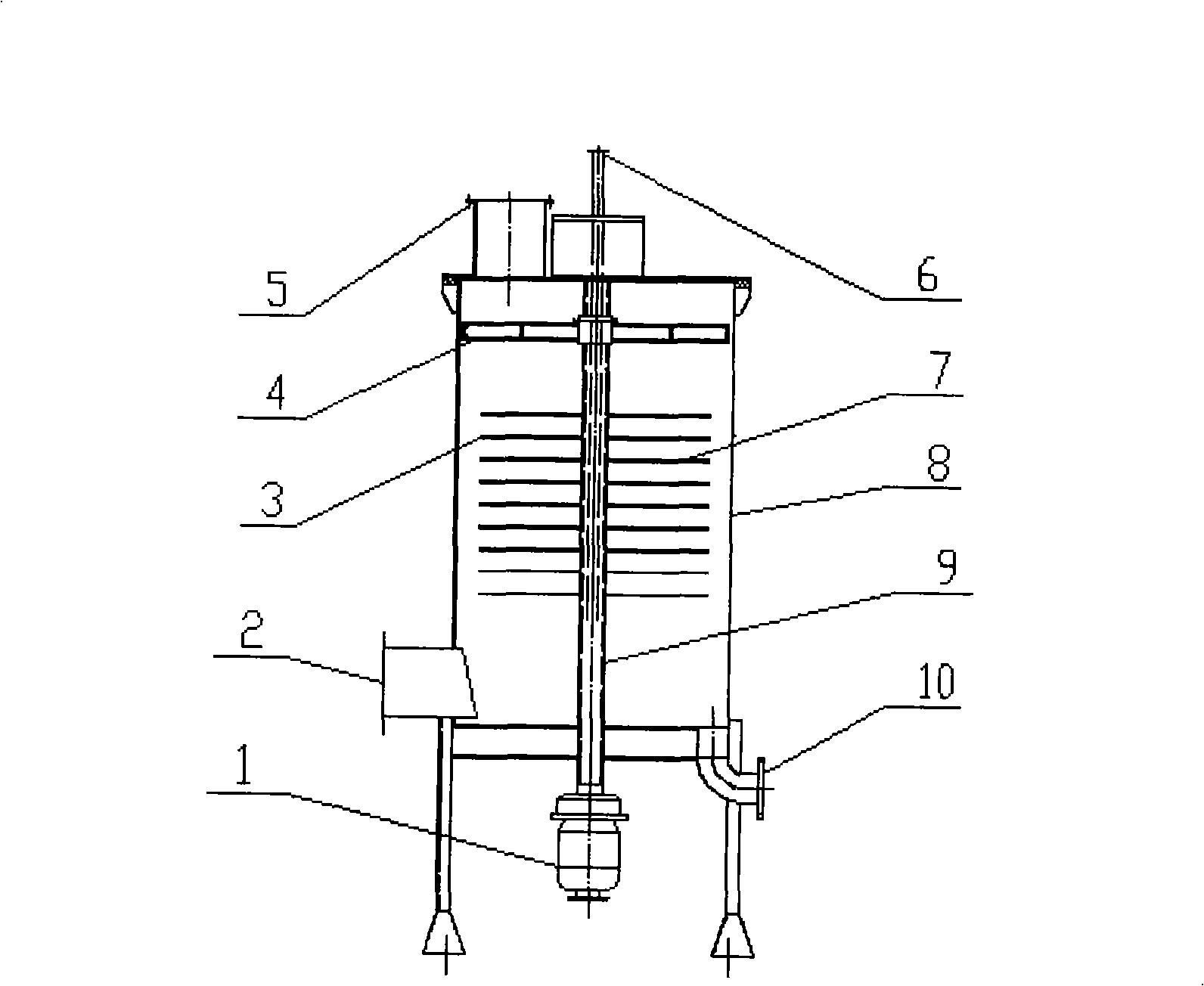

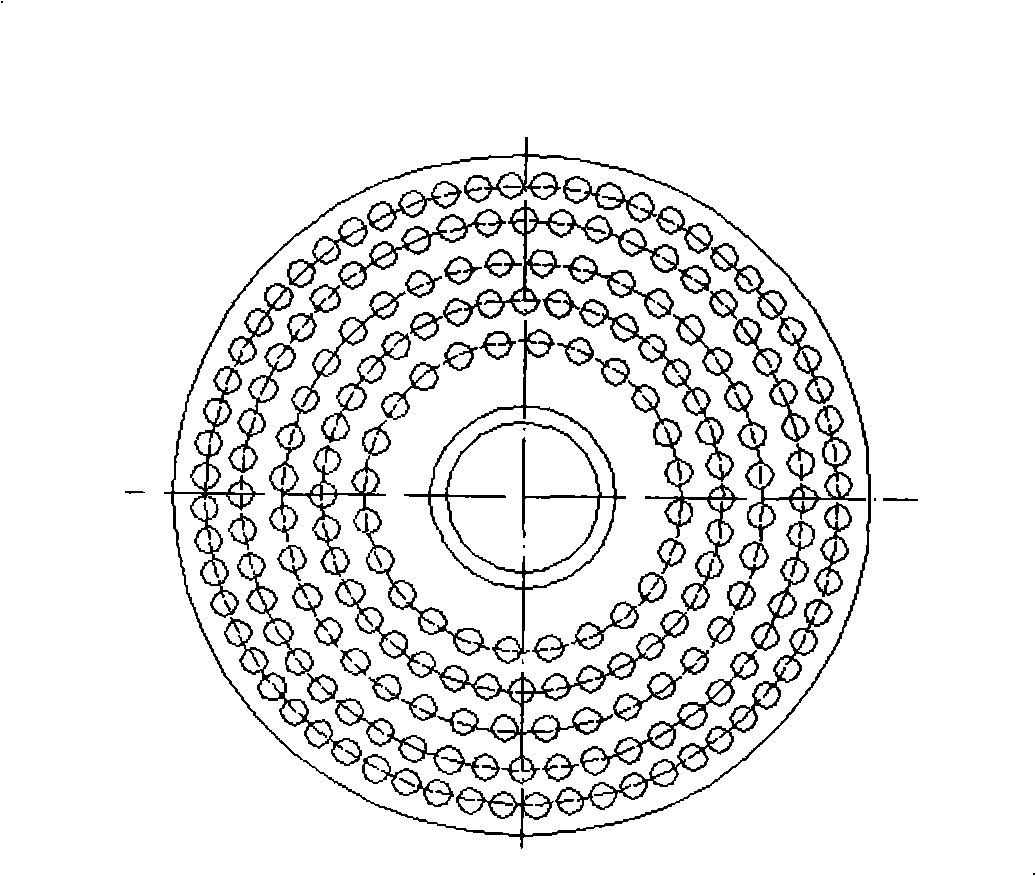

[0023] figure 1 A structural form of the cross-flow high-gravity rotary bed of the spaced plane screen packing type of the present invention is shown. Such as figure 1 As shown, the cross-flow supergravity rotary bed of the spaced planar screen packing type includes a housing 8, a rotating shaft 9, a flat screen 7, a motor 1 and a rotary demister 4, and the rotary demister 4 is fixed by welding or bolts. Way is fixed on the rotating shaft 9. The rotating shaft 9 is located in the center of the cylindrical housing 8 and is connected with the motor 1. The lower end of the housing 8 is provided with an air inlet 2 and a liquid outlet 10 respectively, and the upper end is provided with an air outlet 5; the rotating shaft located in the housing is made of porous stainless steel seamless Tubes, or seamless tubes made of titanium can also be used. The rotating shaft 9 is a hollow structure, the upper end is provided with a liquid inlet 6, and the rotating shaft 9 is provided with ...

Embodiment 2

[0029] Different from Embodiment 1, the present embodiment has three planar screens 9 in total. The planar screens are made of PP as a skeleton, and PE screens are arranged on them; The flat screen is fixed on the drum by welding. After testing, compared with the ordinary multi-stage atomized rotary bed, the total heat transfer coefficient of this kind of enhanced multi-stage atomized high-gravity rotary bed with spaced apart plane screens is increased by 4%, and the total mass transfer coefficient is improved. 3%, dust removal efficiency increased by 6%.

Embodiment 3

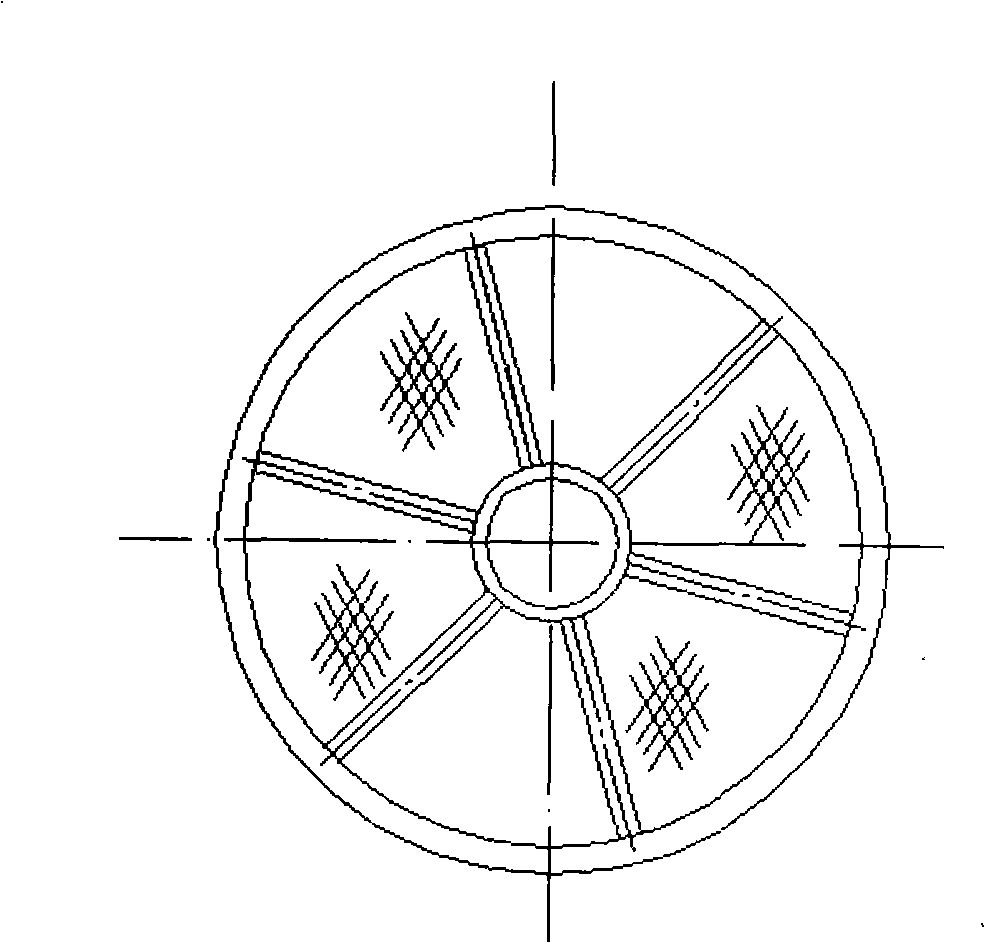

[0031] Different from Embodiment 1, the present embodiment has 3 flat screens in total, and the flat screen is a porous screen perpendicular to the axial direction and horizontal, such as Figure 2A As shown, the flat screen is a screen with two layers of stainless steel wire mesh fixed on a stainless steel structure. The flat screen plates are installed at intervals on the rotating shaft. The rotating shaft is a porous seamless stainless steel pipe, the distance between the flat screens is 200mm, the outer diameter of the flat screens is 300mm, and the flat screens are fixed on the ribs of the drum by welding. After testing, compared with the ordinary multi-stage atomized rotary bed, the total heat transfer coefficient of the enhanced multi-stage atomized high-gravity rotary bed with spaced apart planar screens is increased by 4.5%, and the total mass transfer coefficient is improved. 4%, dust removal efficiency increased by 6.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com