Method for producing gas hydrated compound and device

A gas hydrate and gas generation technology, applied in the direction of mixing methods, chemical methods for reacting liquid and gas media, chemical instruments and methods, etc., can solve problems such as short induction time, large energy consumption, and insufficient density of hydrates , to achieve the effects of short induction time, good heat transfer performance, and dense gas hydrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

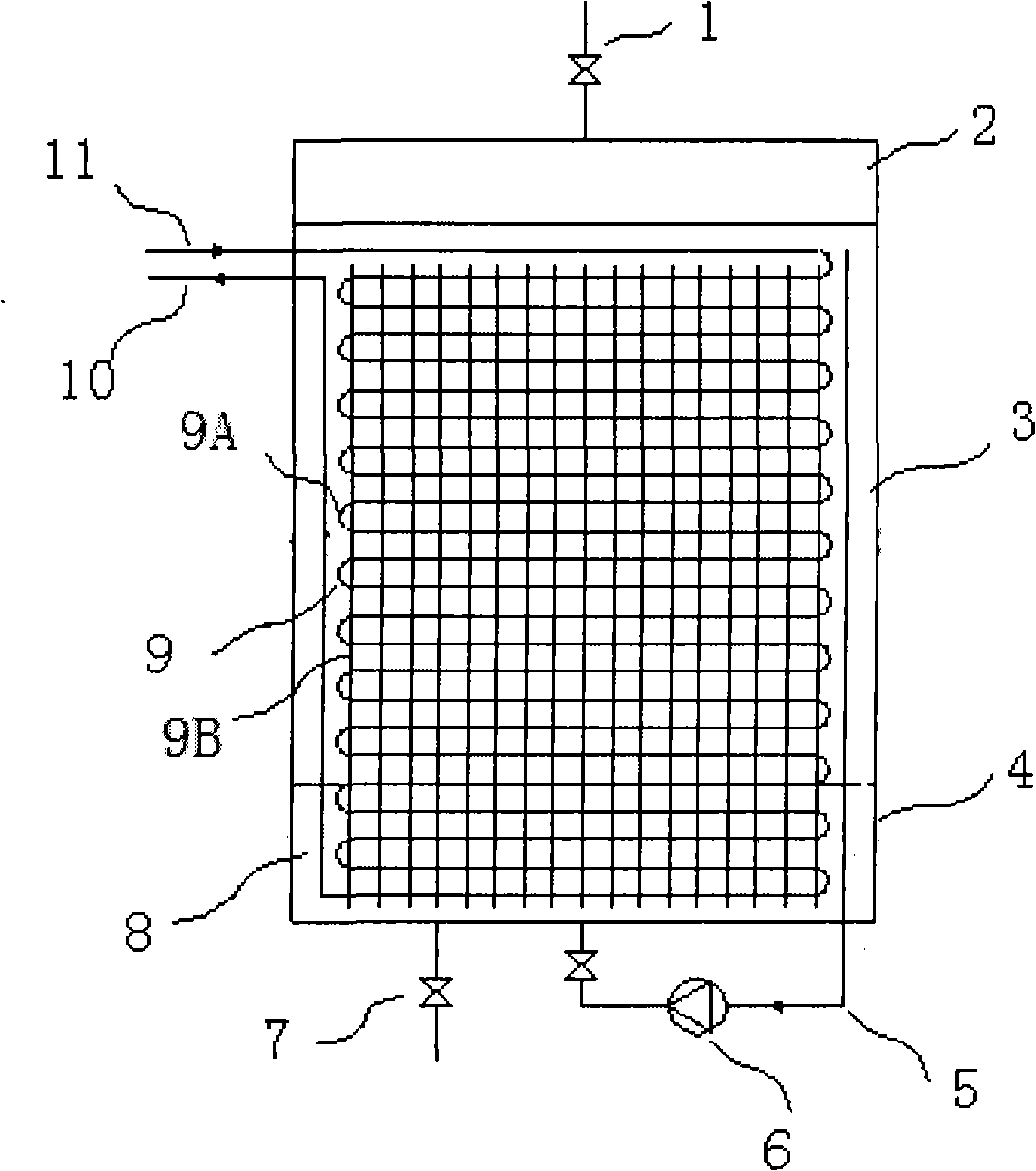

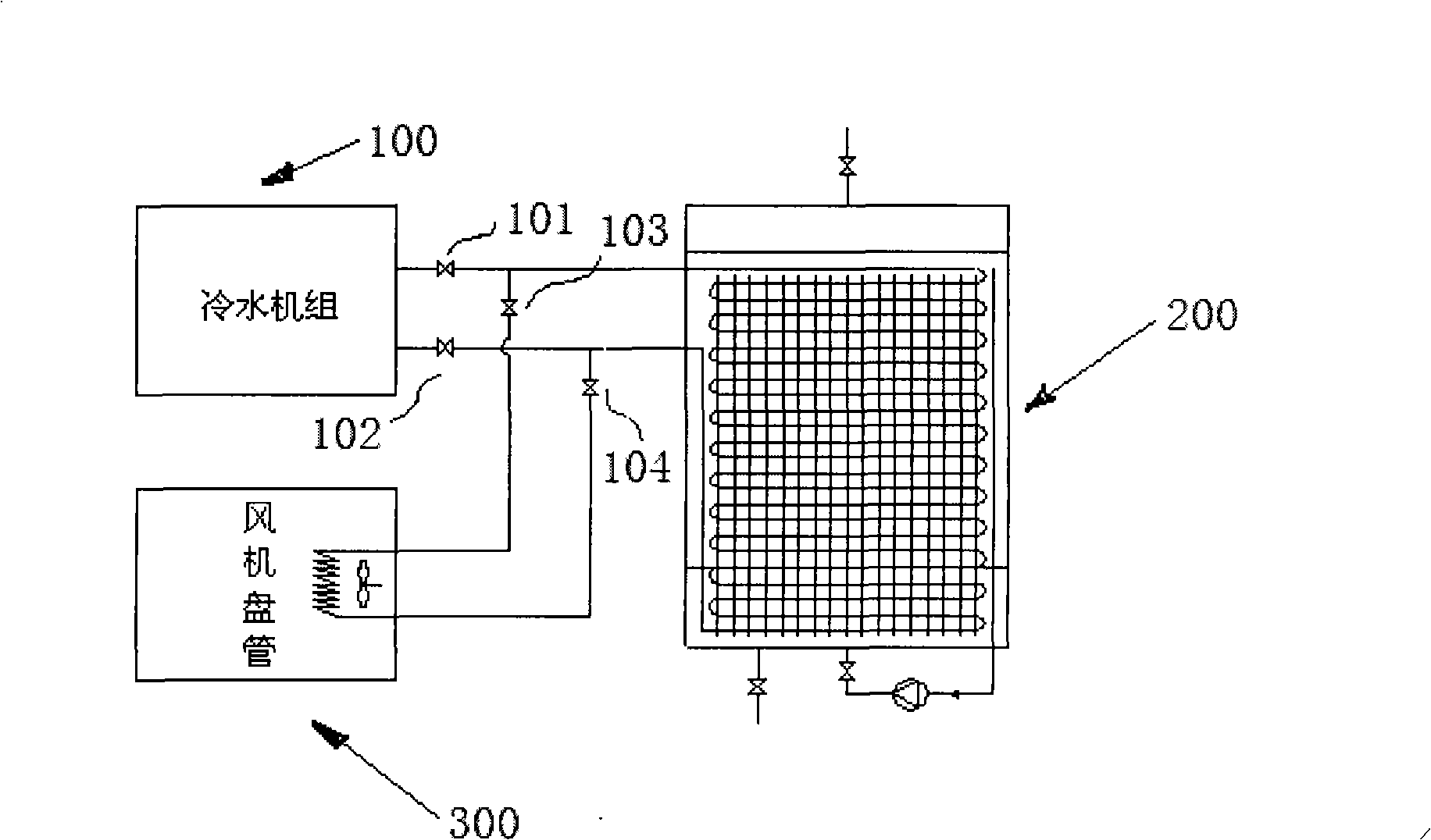

[0019] like figure 1 The static fast-generating gas hydrate reaction tank 200 is shown. As shown in the figure, the reaction tank 200 is mainly composed of a stainless steel tank body 8 with thermal insulation material, a serpentine heat exchanger 9 with vertical metal fins, two ends respectively connected to the liquid water phase space 3 and the liquid hydrate space 4 It is composed of connected crystallization promoting pumps 6, and outside the reaction tank is a reactant injection pipe 1, a reactant discharge pipe 7, a heat exchanger input port 11, a heat exchanger output port 10, and a water outlet pipe 5.

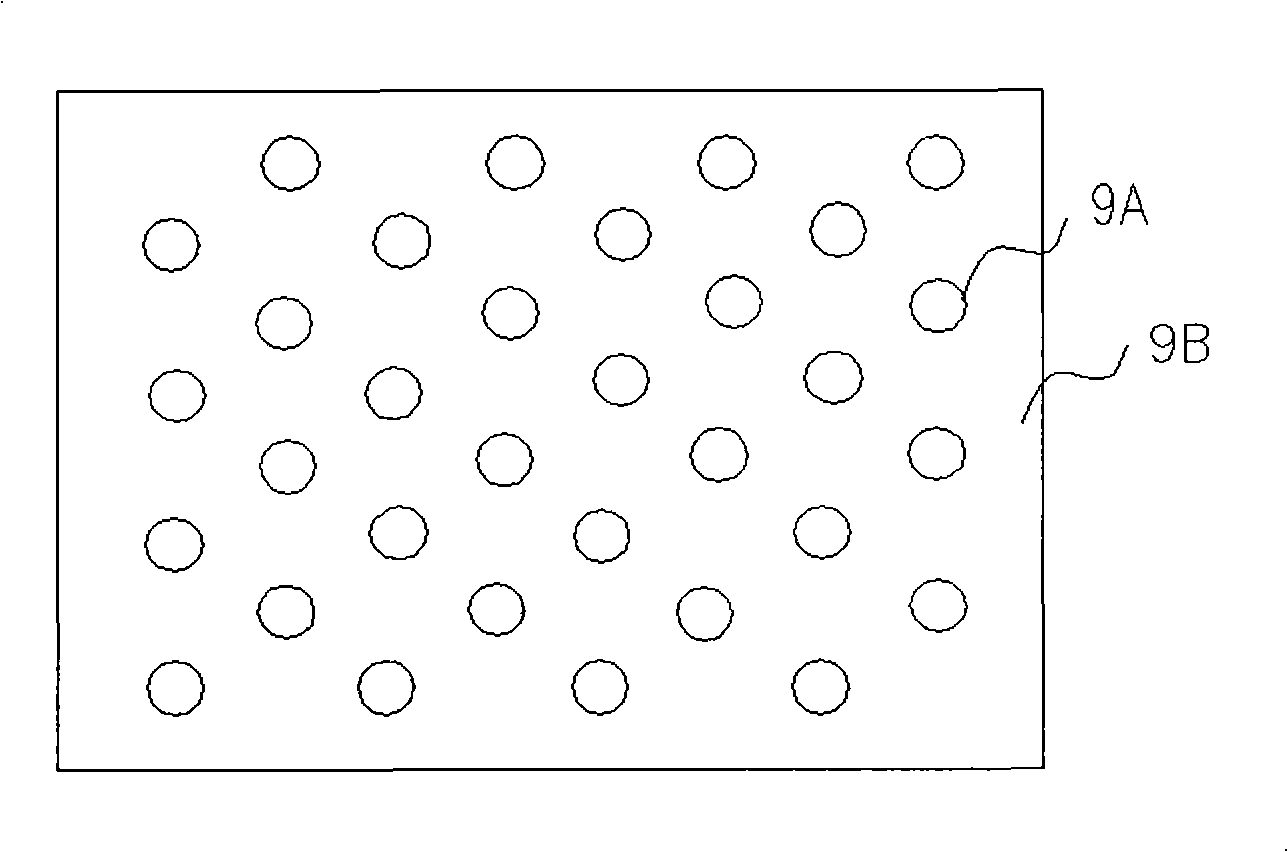

[0020] like figure 2 The cross-sectional schematic diagram of the serpentine heat exchanger shown, the heat exchange tube 9A of the serpentine heat exchanger 9 is covered with vertical metal fins 9B with large thermal conductivity and large surface polar free energy, and the height of the metal fins 9B penetrates through. at the vertical height of the entire reacta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com