Preparation of epicholorohydrin-dimethylamine kation alta-mud grain

A polyepichlorohydrin and dimethylamine cation technology, applied in the environmental field, can solve problems such as no bentonite particles, and achieve the effects of excellent adsorption performance, economical efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

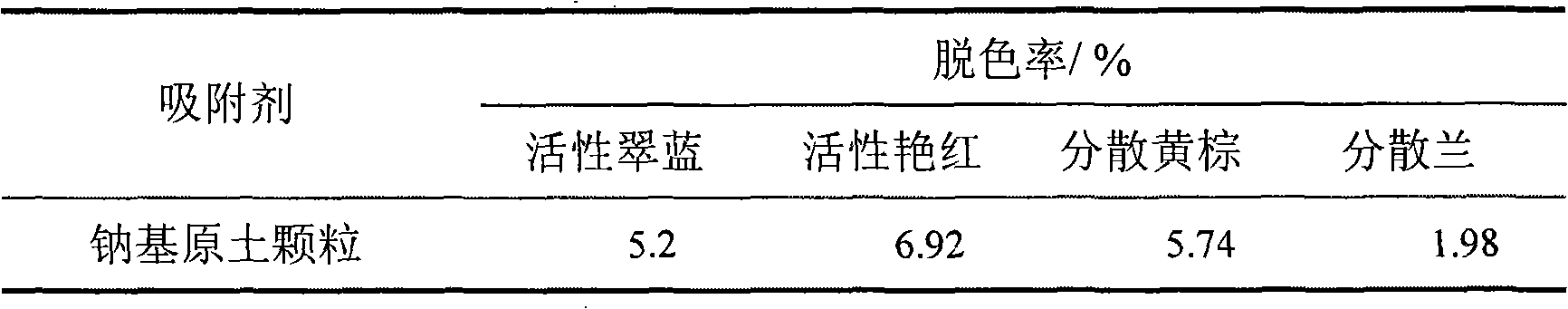

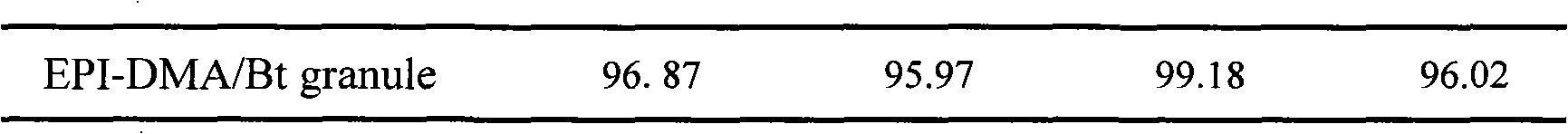

Examples

Embodiment

[0026] The preparation method of polyepichlorohydrin dimethylamine cationic bentonite particles, the steps are as follows:

[0027] (1) In parts by weight, weigh 20.0 g of dried sodium-based bentonite, 4.0 g of coal powder, and 0.4 g of starch in an open glass container, add water, stir evenly and adjust to viscous, and pass through 20 mesh Sieve extrusion granulation and drying to obtain bentonite particles with a diameter of 1-2mm;

[0028] (2) Place the particles prepared above in a muffle furnace, burn them at a high temperature of 600°C for 6-8 hours, and cool them down to room temperature naturally to make porous bentonite particles;

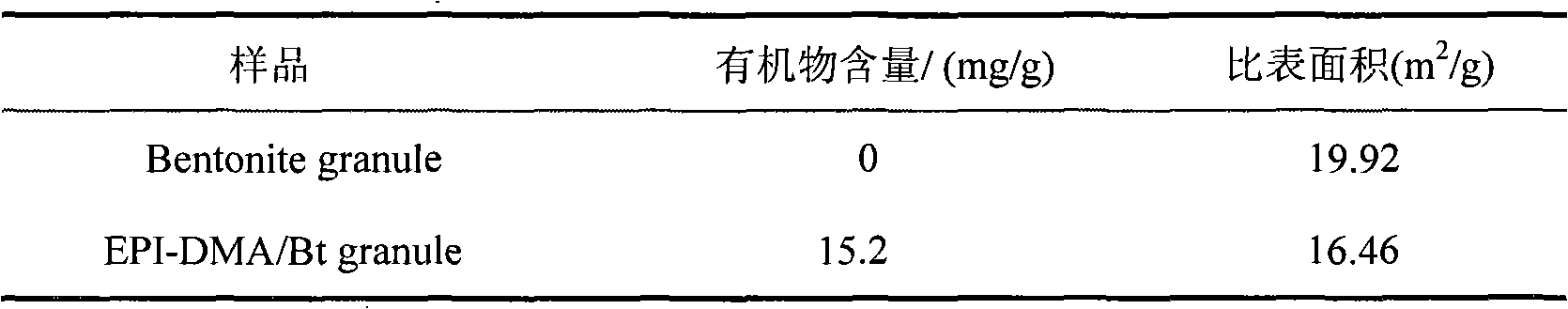

[0029] (3) According to the ratio of porous bentonite particles: polyepichlorohydrin dimethylamine solution=1g: 25mL, polyepichlorohydrin dimethylamine solution is added to organically load the prepared porous bentonite particles to obtain porous bentonite particles and The reaction solution of polyepichlorohydrin dimethylamine solution; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cation exchange capacity | aaaaa | aaaaa |

| Cationic degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com