Preparation of nano cadmium tantalite photocatalyst

A photocatalyst, nano-tantalum technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor product particle size and uniformity, catalyst sintering and agglomeration , easy to introduce impurities and other problems, to achieve the effect of narrowing the band gap, good photocatalytic water splitting performance, and improving the photocatalytic reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, 1) at first, in the water bath of 50 ℃, the cadmium nitrate tetrahydrate of the tantalum pentachloride of 0.01mol and 0.01mol is dissolved in the dehydrated alcohol of 40g, then, the polyethylene glycol of 20g (6000) is dissolved in the dehydrated alcohol of 40g;

[0028] 2) Next, mix the above two solutions under magnetic stirring, and evaporate the solvent in a water bath at 90°C to obtain a transparent sol;

[0029]3) Place the obtained sol in an oven at 150°C, air-dry it to obtain a xerogel, and then grind it to obtain a light yellow precursor powder;

[0030] 4) The precursor powder is placed in a muffle furnace, calcined at 450°C for 5 hours, the dispersant polyethylene glycol is removed, the temperature is lowered to room temperature, and the gray powder is obtained;

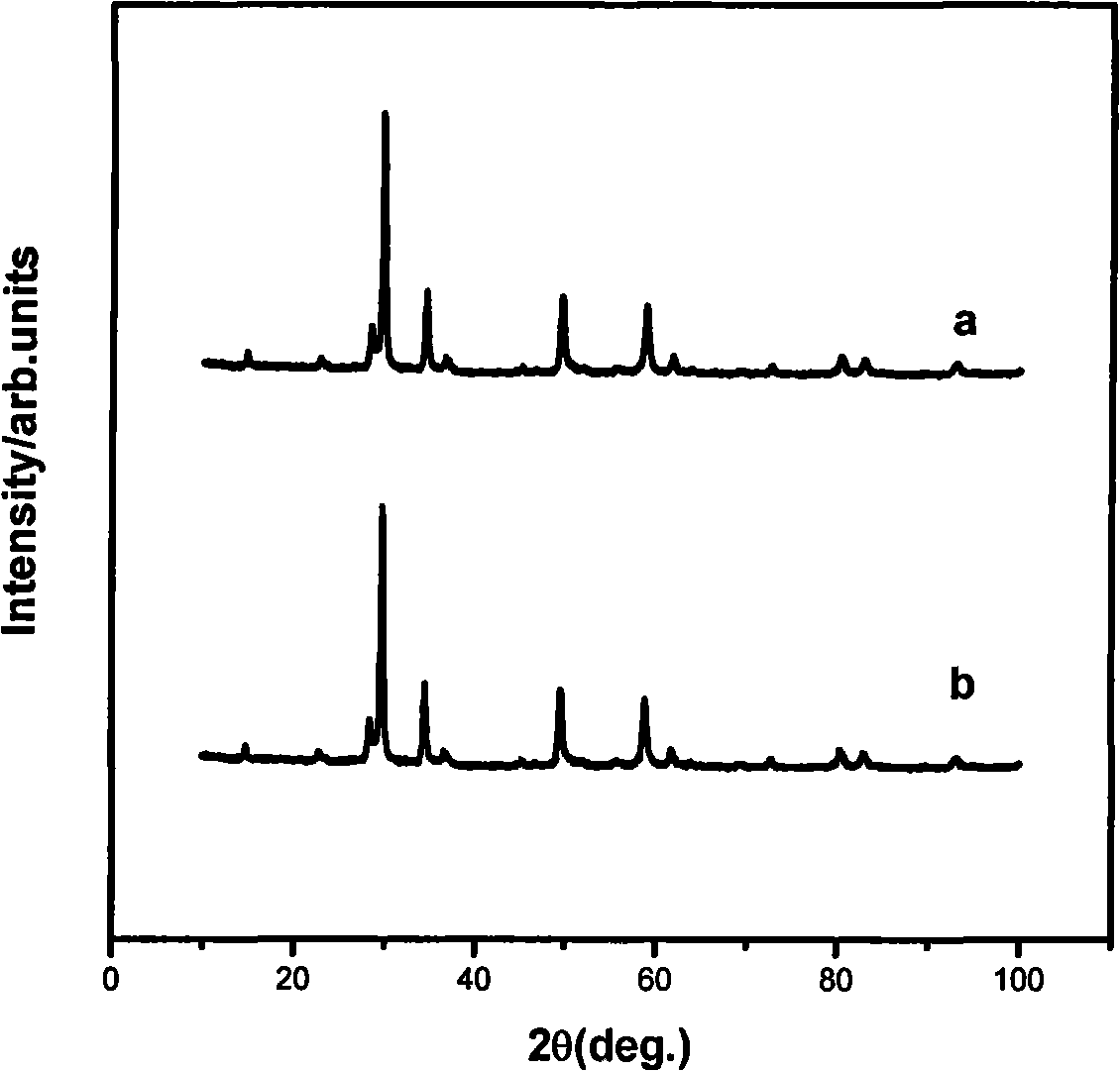

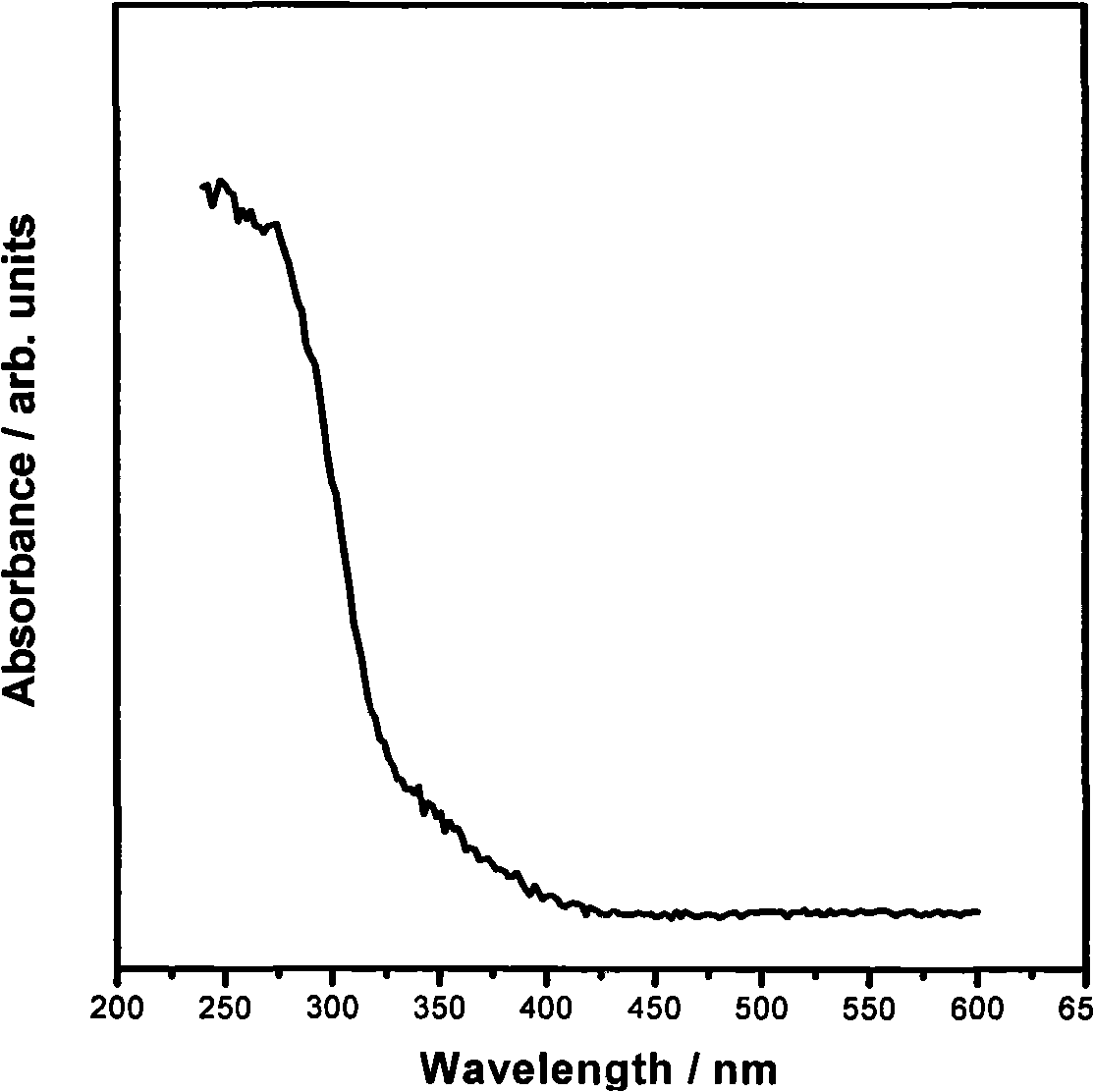

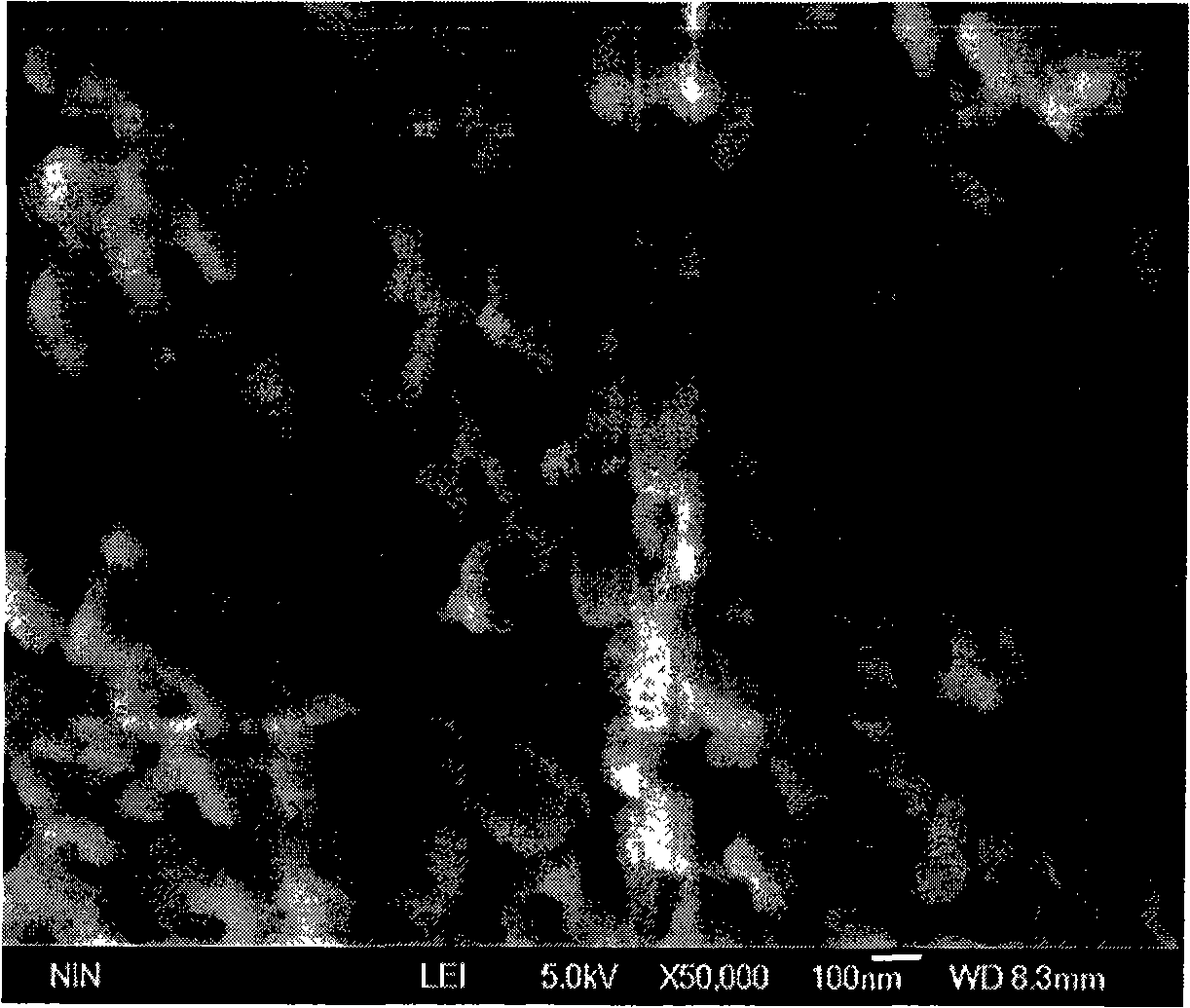

[0031] 5) The gray powder is placed in a muffle furnace, calcined at 900° C. for 2 hours, and then naturally lowered to room temperature to obtain a white nano-cadmium tantalate phot...

Embodiment 2

[0032] Embodiment 2, 1) at first, in the water bath of 70 ℃, the cadmium nitrate tetrahydrate of the tantalum pentachloride of 0.01mol and 0.01mol is dissolved in the dehydrated alcohol of 30g, then, the polyethylene glycol of 18g (6000) was dissolved in 30g of absolute ethanol;

[0033] 2) Next, mix the above two solutions under magnetic stirring, and evaporate the solvent in a water bath at 70°C to obtain a transparent sol;

[0034] 3) Place the obtained sol in an oven at 120°C, air-dry it to obtain a xerogel, and then grind it to obtain a light yellow precursor powder;

[0035] 4) The precursor powder is placed in a muffle furnace, calcined at 300°C for 6 hours, the dispersant polyethylene glycol is removed, the temperature is lowered to room temperature, and the gray powder is obtained;

[0036] 5) The gray powder is placed in a muffle furnace, calcined at 900° C. for 5 hours, and then naturally lowered to room temperature to obtain a white nano-cadmium tantalate photocat...

Embodiment 3

[0037] Embodiment 3, 1) at first, in the water bath of 60 ℃, the cadmium nitrate tetrahydrate of the tantalum pentachloride of 0.01mol and 0.01mol is dissolved in the dehydrated alcohol of 25g, then, the polyethylene glycol of 25g (6000) is dissolved in the dehydrated alcohol of 25g;

[0038] 2) Next, mix the above two solutions under magnetic stirring, and evaporate the solvent in a water bath at 100°C to obtain a transparent sol;

[0039] 3) Place the obtained sol in an oven at 100°C, air-dry it to obtain a xerogel, and then grind it to obtain a light yellow precursor powder;

[0040] 4) Place the precursor powder in a muffle furnace, calcinate at 500°C for 4 hours, remove the dispersant polyethylene glycol, cool down to room temperature, take it out and grind it, and obtain a gray powder;

[0041] 5) The gray powder is placed in a muffle furnace, calcined at 900° C. for 3 hours, and then cooled down to room temperature naturally to obtain a white nano-cadmium tantalate pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com