Atomizing disk of high speed centrifugal type atomizer

A high-speed centrifugal and atomizer technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of bearing lubricating grease loss, atomizer speed reduction, noise, vibration, etc., to ensure concentricity degree, increase the number of nozzles, reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

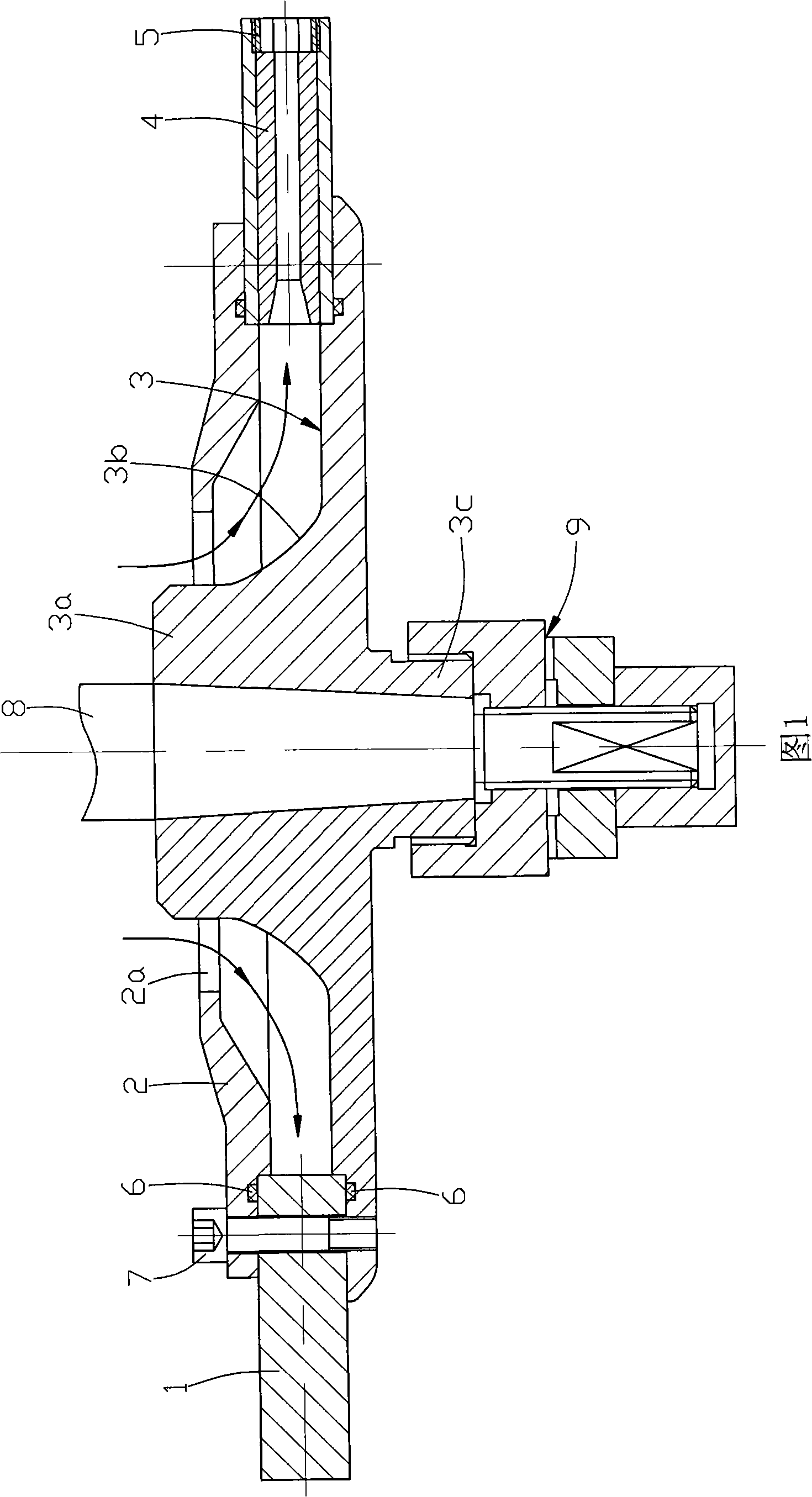

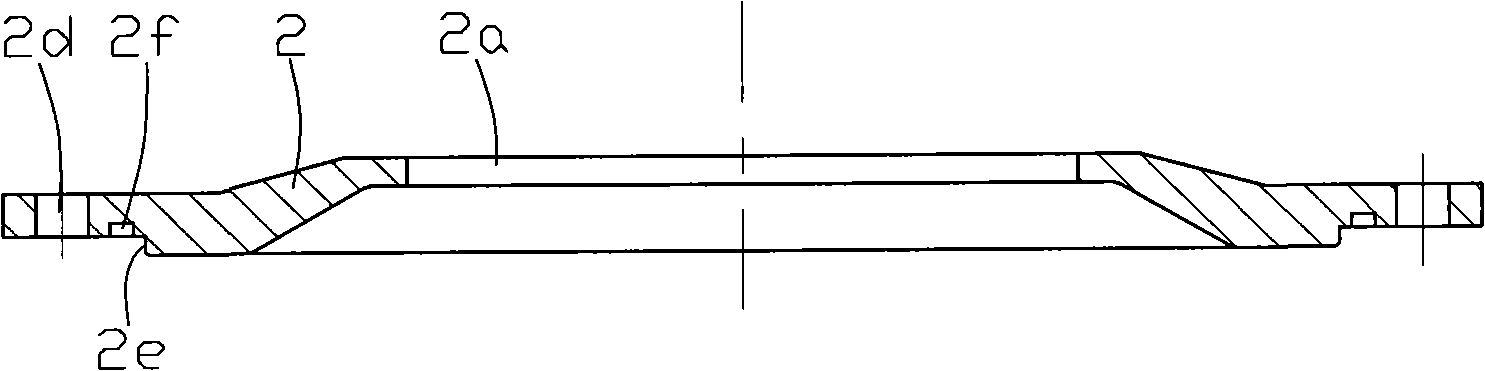

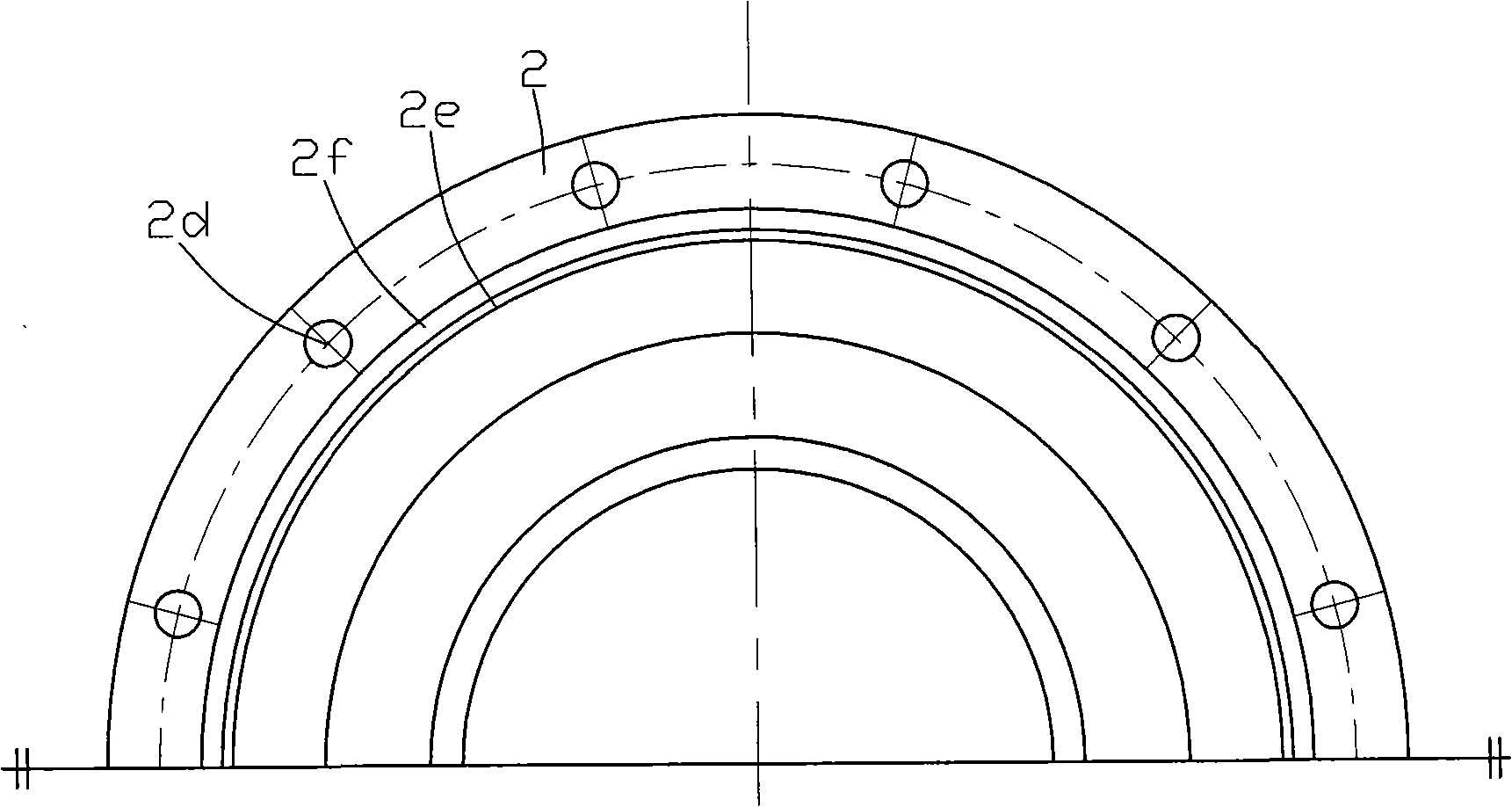

[0032] Figure 1, figure 2 with image 3 As shown, the present invention is made of parts such as nozzle disc 1, disc-shaped loam cake 2, disc-shaped base 3, nozzle 4, plug 5, sealing ring 6 and screw 7. Wherein the center of disc-shaped loam cake 2 is provided with feed hole 2a, and this feed hole 2a is made up of upper straight section and lower conical section, and wherein the minimum end of lower conical section is on, and the diameter of lower conical section minimum end is larger than described The diameter of the upper straight segment. A plurality of through holes 2d are evenly distributed on the circumference of the disc-shaped upper cover 2 near its edge, and the lower surface of the disc-shaped upper cover 2 located inside the through hole 2d is provided with a circular limit step 2e, which is connected to the through-hole 2d. An annular groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com