Mortar and concrete modified by emulsified asphalt

A technology for emulsification of asphalt and concrete, applied in the field of cement mortar and concrete, can solve the problems of less application of concrete, high price, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

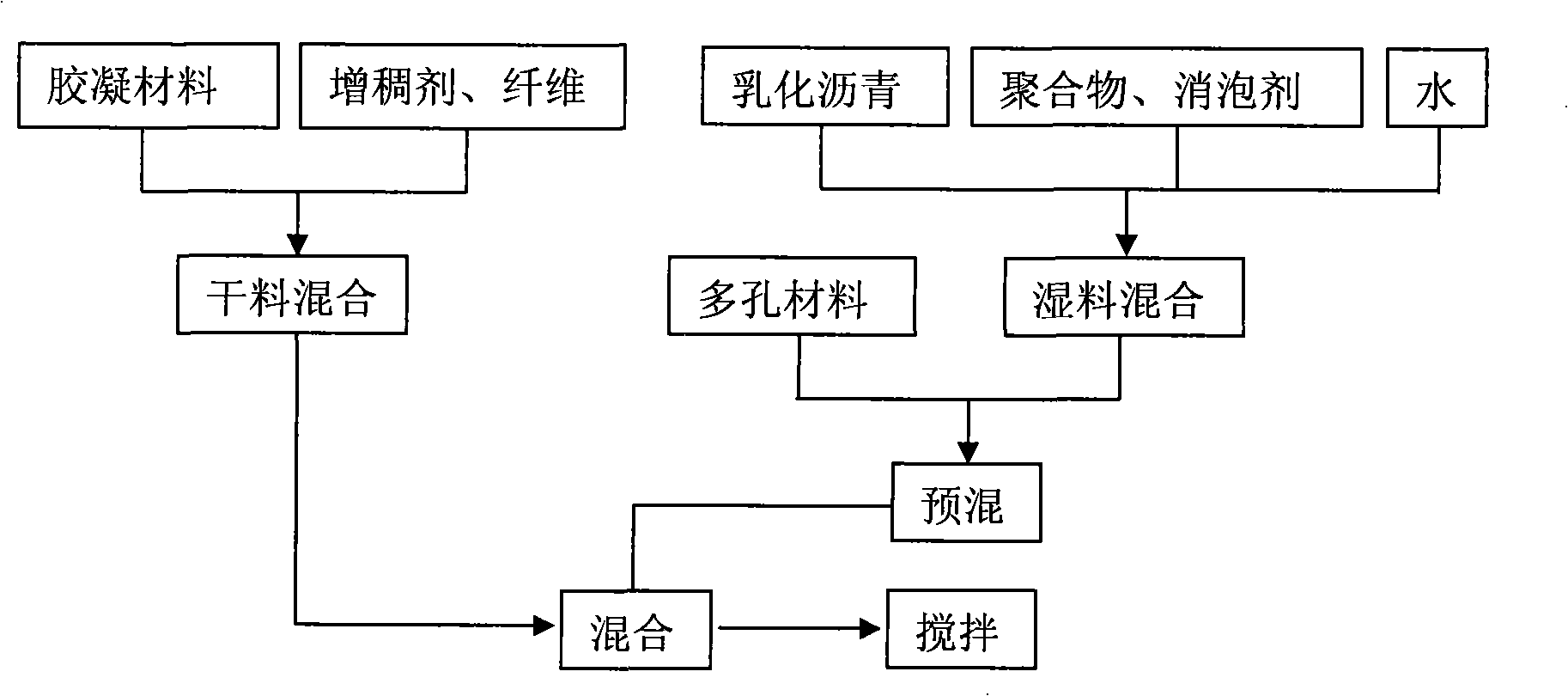

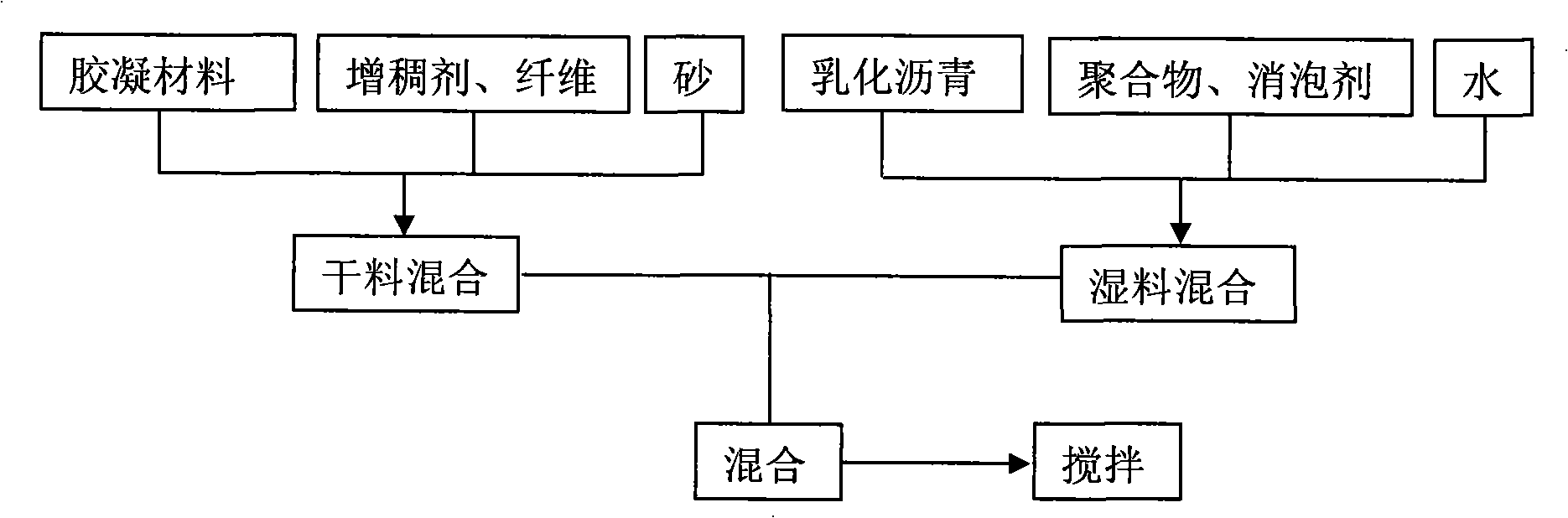

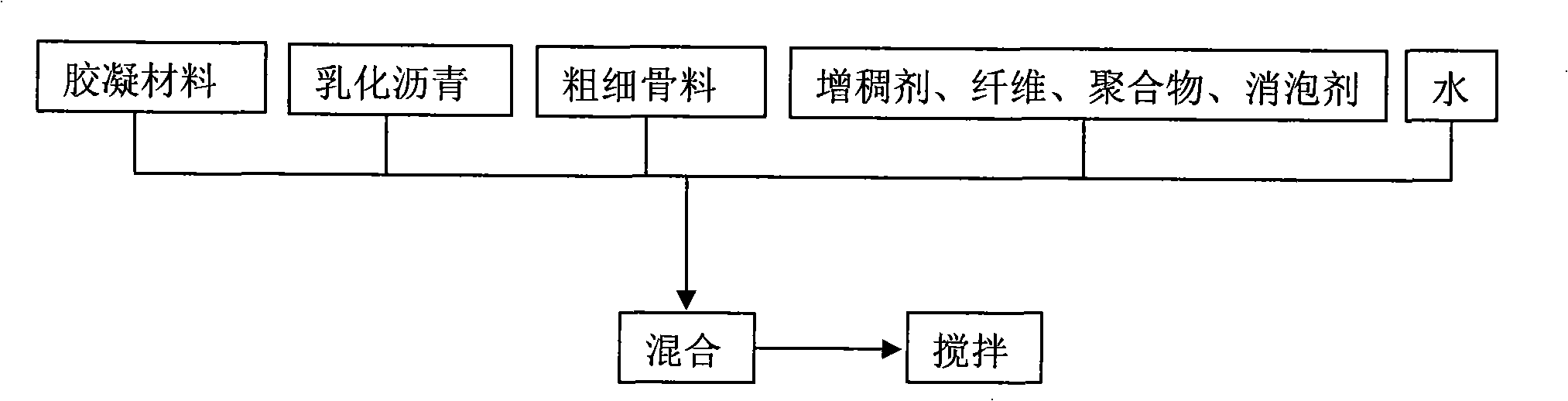

Method used

Image

Examples

Embodiment 1

[0089] Mix the required raw materials according to the following table (the foam particles are added by volume)

[0090]

[0091] 1 Stir at 30r / min for 4min by mortar mixer, stop for 1min, and then stir at 45r / min for 2min.

[0092] The performance test of the thermal insulation mortar prepared according to this ratio is as follows:

[0093] Compressive strength (14 days) 475.6KPa Thermal conductivity 0.065W / (m·K)

[0094] Dry apparent density 385.3kg / m 3 Softening factor 0.76

Embodiment 2

[0096] Mix the required raw materials according to the following table (the foam particles are added by volume)

[0097]

[0098] Stir at 25r / min for 4min by mortar mixer, stop for 1min, and then stir at 40r / min for 2min.

Embodiment 3

[0100] Mix the required raw materials according to the following table (the foam particles are added by volume)

[0101]

[0102] Stir for 4 minutes at a speed of 30r / min by a mortar mixer, stop for 1 minute, and then stir at a speed of 45r / min for 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com