Optical fibre sensor with variable precision

A fiber optic sensor and variable precision technology, applied in the field of sensors, can solve the problems of inability to accurately measure the liquid level in real time, high precision limitations, etc., and achieve variable precision liquid level measurement, high precision accurate measurement, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

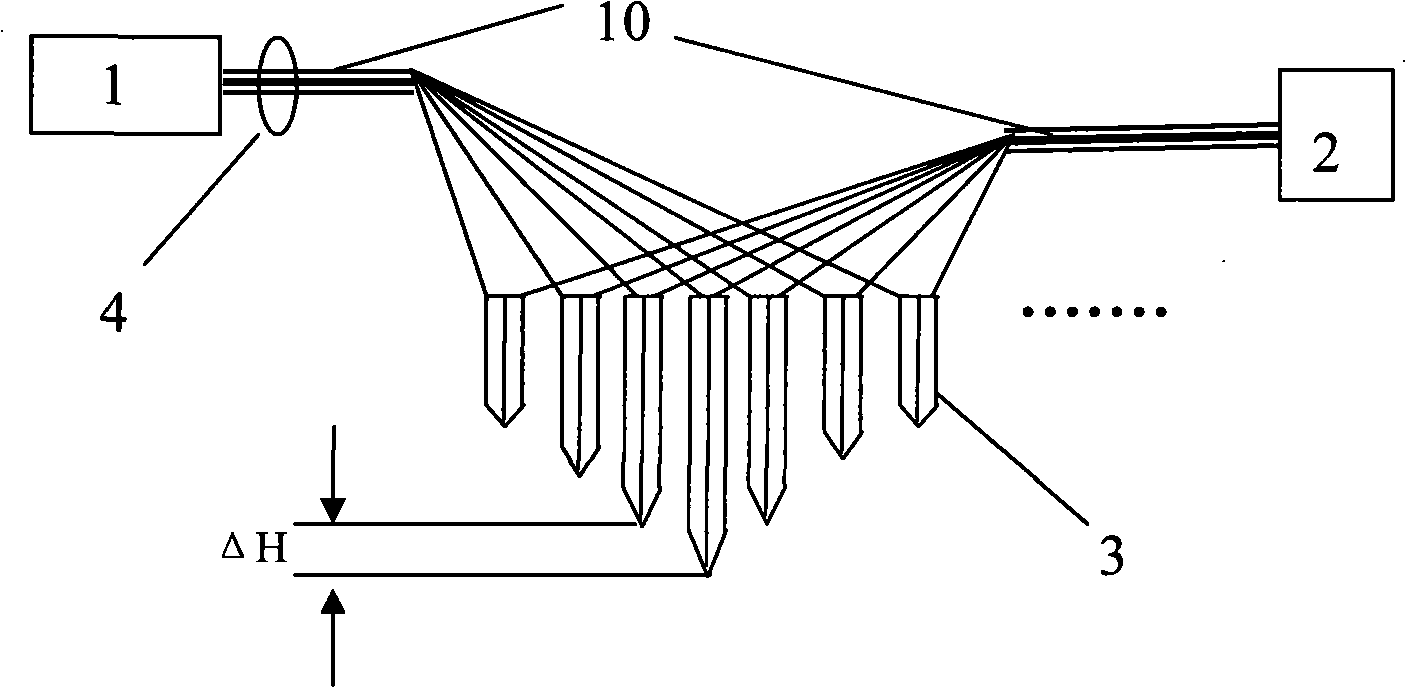

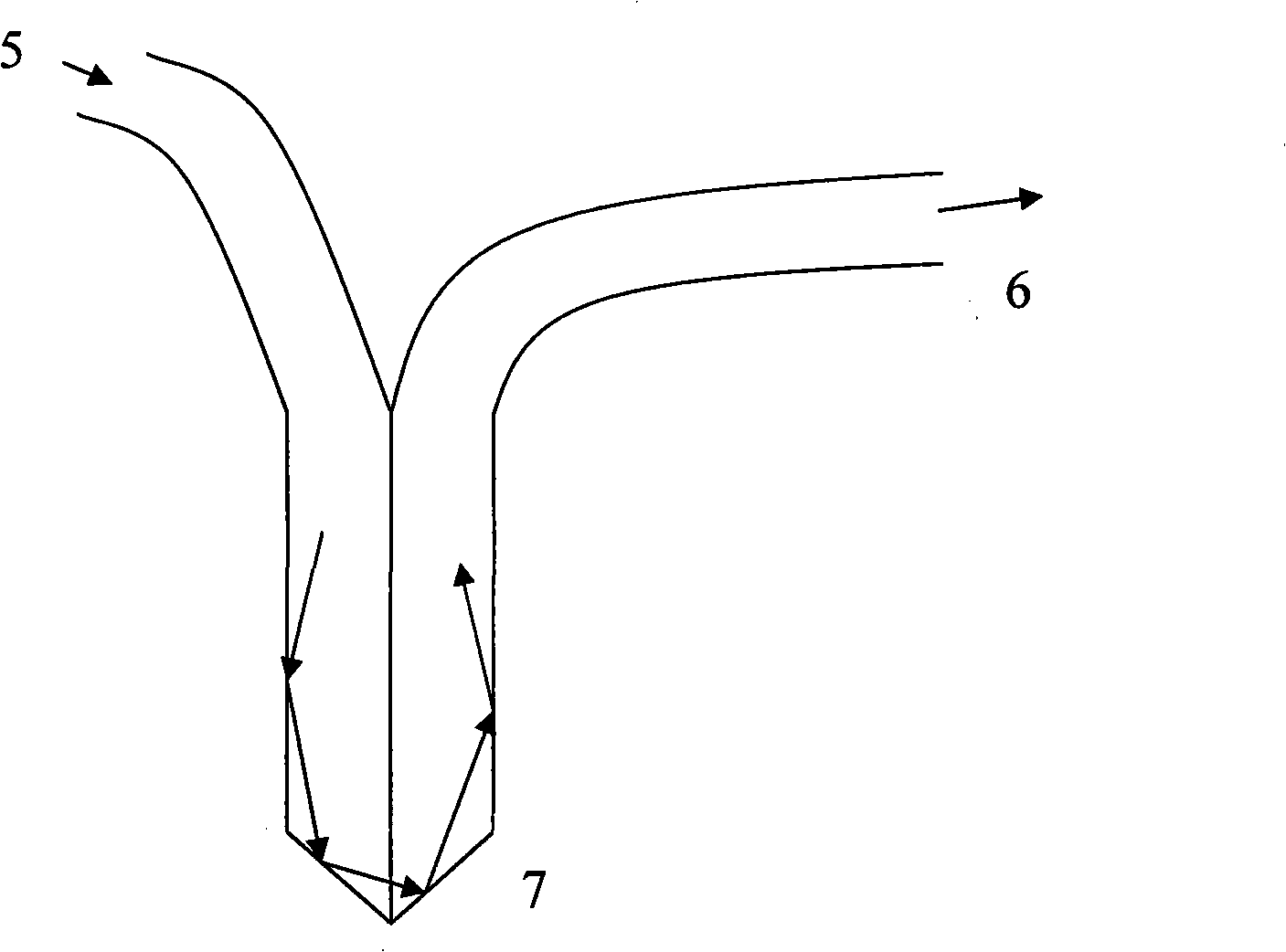

[0024] see figure 1 , figure 2 , a liquid level measurement sensor with variable precision, consisting of a light source 2 (laser or photodiode), a dual fiber optic probe 2 and an optical cable 10, a focusing lens 4, and a light receiving device 1 (CCD, CMOS, photodiode, etc.). Multiple dual fiber optic probes 2 are arranged according to a certain height difference ΔH. Each double fiber optic probe 2 can achieve a certain range of measurement accuracy through the height difference ΔH. Extend the dual fiber optic probes 2 into the measured liquid to the bottom. According to the formula n1Sinθ1=n2Sinθ2, when the refractive index n2 becomes larger, the refraction angle θ2 decreases, and when the refractive indices of the two media are closer, the closer Total reflection is not easy to occur, that is, the light is directly refracted into the second medium, which is why the light intensity at the exit end of the dual fiber optic probe 2 will be darker when immersed in the liquid...

Embodiment 2

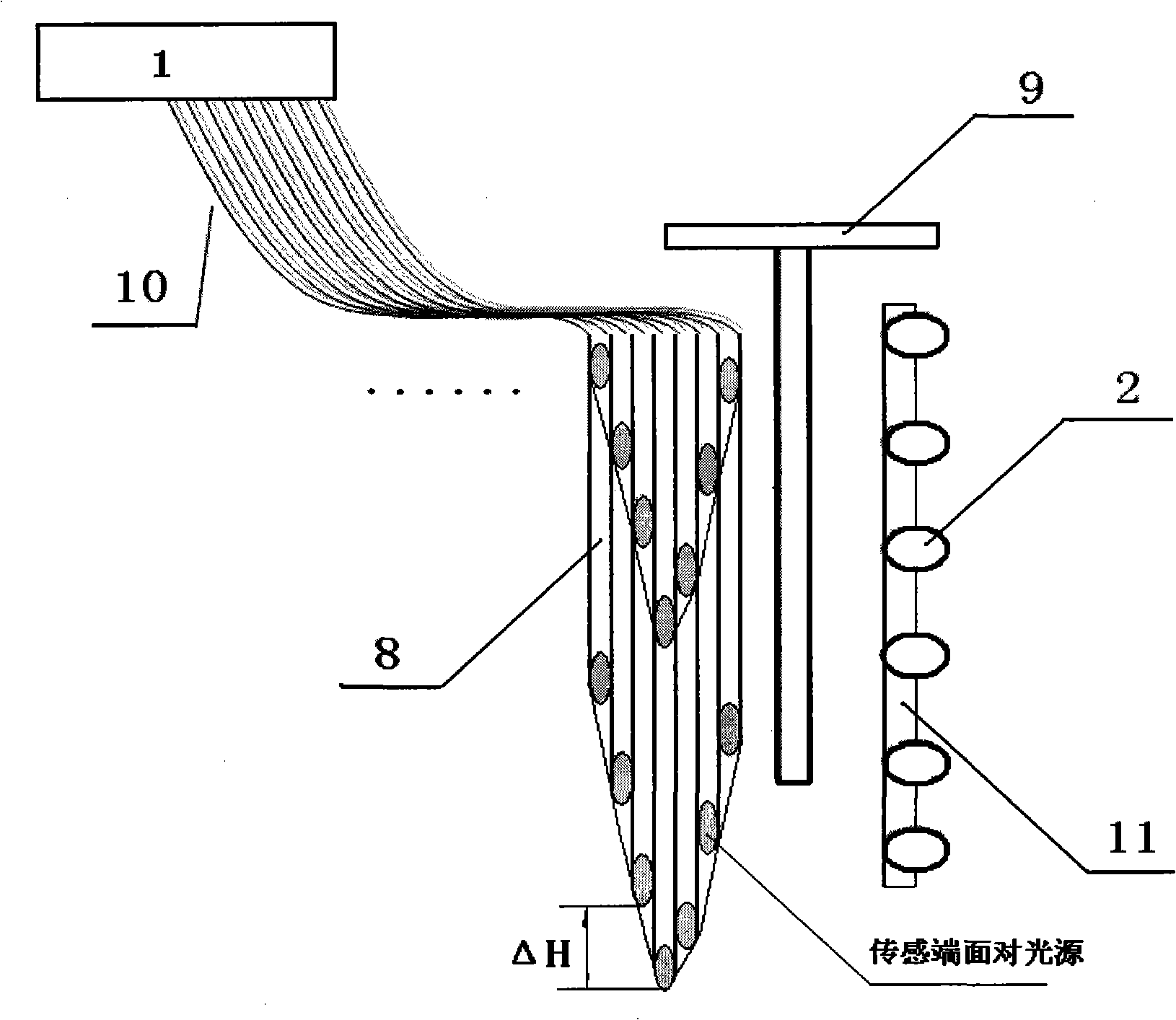

[0028] see image 3 , a variable precision displacement measurement sensor, the optical fiber displacement sensor is composed of a light source 2, a single optical fiber probe 8 and an optical cable 10, a shading plate 9, a light receiving device 1 and the like. The light source 2 is composed of a plurality of light-emitting diodes from bottom to top to form a linear point light source, and is converted into a relatively uniform line light source through a uniform light plate 11 (such as frosted glass, etc.) that uniformizes the light. A plurality of single-fiber probes 8 are arranged according to a certain height difference ΔH, and the light incident end of each single-fiber probe 8 forms a 45° inclined plane with the fiber core axis to form a sensing end face and is opposite to the light-emitting diode; A light-shielding plate 9 that can move up and down is arranged between them; the optical fiber at the light output end of each single fiber probe 8 is led out to form an opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com