Pressure-change absorption separation method for ethylene and hydrogen from refining plant dry gas

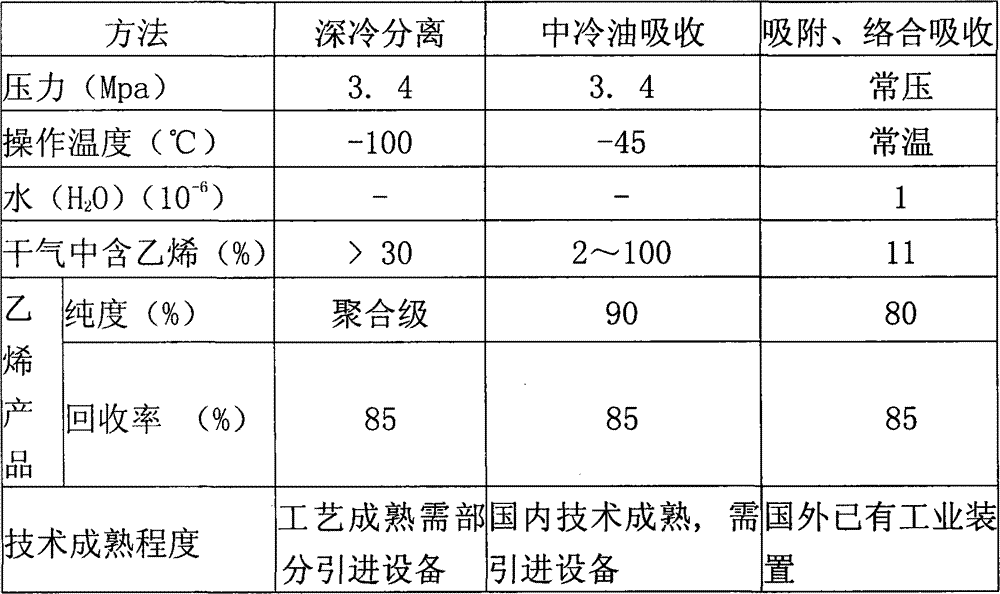

A pressure swing adsorption and refinery dry gas technology, applied in the direction of adsorption purification/separation, hydrogen separation, hydrogen separation using solid contact, etc., can solve problems such as inability to effectively achieve simultaneous separation of ethylene and hydrogen, harsh operating conditions, etc. , to achieve low cost, reduce air emissions, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0035] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

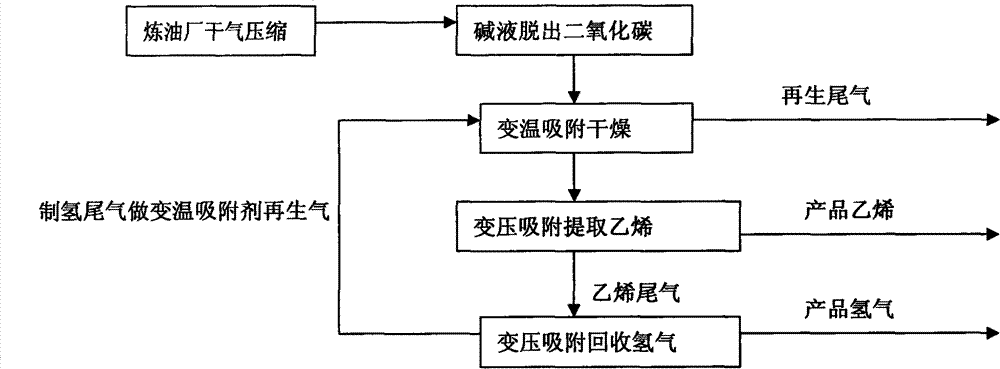

[0036] as attached figure 1 As shown, the method for separating ethylene and hydrogen in the dry gas of the refinery by pressure swing adsorption is carried out in the following steps:

[0037] The first step of carbon dioxide removal: use lye to remove carbon dioxide from refinery dry gas with an inlet pressure of 0.3Mpa or 0.4Mpa or 0.8Mpa and normal temperature;

[0038] The second step of dehydration: the dry gas of the refinery that removes carbon dioxide in the first step is subjected to adsorption and dehydration with a conventional desiccant;

[0039] The third step is pressure swing adsorption extraction of ethylene: the refinery dry gas d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com