Exact filtration for refining furfuryl alcohol, continuous distillation composite technique and device for the same

A technology of precision filtration and composite process, applied in the field of furfuryl alcohol rectification, can solve the problems of small processing capacity of a single set of equipment, no continuous production, high labor intensity of workers, etc., to improve equipment processing capacity, save equipment investment and operation. cost and energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

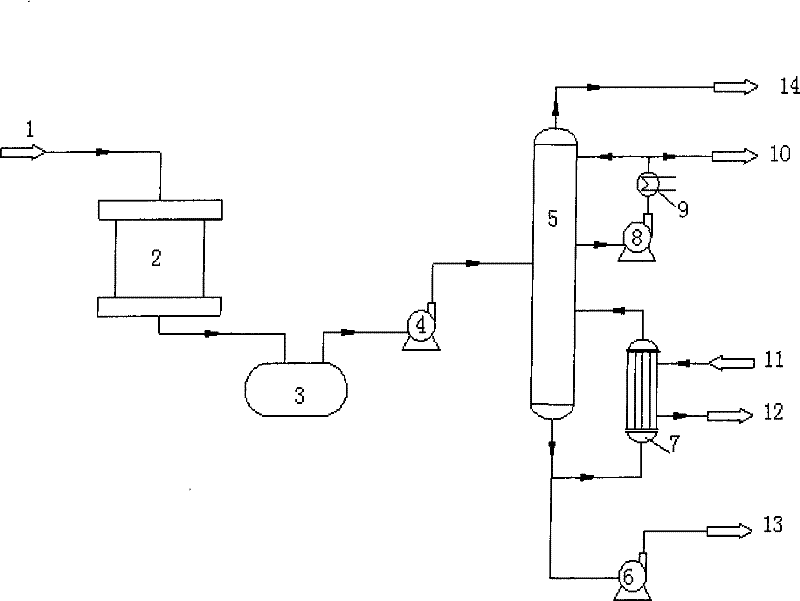

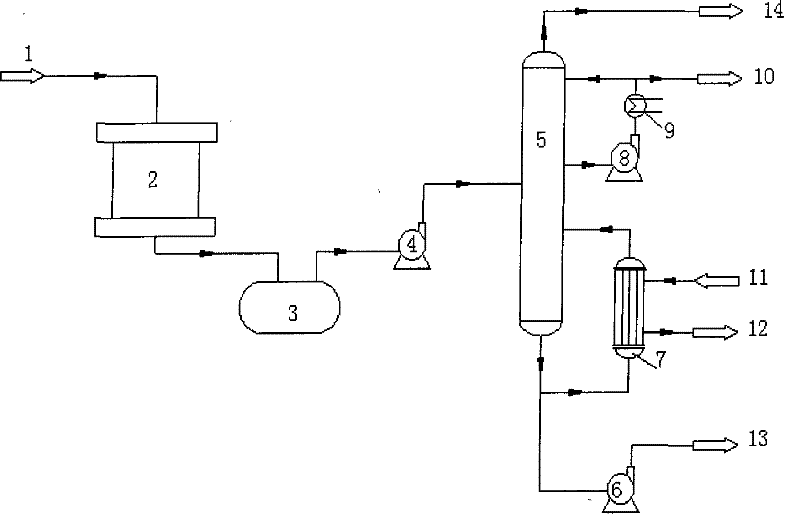

[0016] Accompanying drawing is the present invention is used for crude product furfuryl alcohol refinement fine filtration and continuous rectification composite process schematic diagram, comprises precision filtration equipment 2 and continuous rectification tower 5, passes intermediate storage tank 3, material pump 4, valve and sealing pipeline between them connected. The continuous rectification column 5 is a packed column, and the internal parts adopt structured packing and multi-row hole distributor. Crude furfuryl alcohol 1 is sent from the raw material tank to precision filtration equipment 2 (commercially available disc centrifugal sedimentation machine) through the raw material pump for precision filtration. The separation factor of 5000 removes solid impurities greater than 300 meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com