Highly effective separation purification method for polygalic acid and tenuigenin

A technology of polysapogenin and purification method, which is applied in the field of separation of active components of traditional Chinese medicinal materials, can solve the problems of inability to achieve mass production, large solvent consumption, low monomer yield, etc., and achieves less time consumption and improved processing capacity. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for separating and purifying polygalaic acid and polygalagenin, characterized in that it is carried out according to the following process steps:

[0027] A, the preparation of semi-finished products: take 10 kilograms of the original medicinal material of polygala, add 80 liters of volume percentage concentration and be 70% methanol solution reflux extraction, after extracting liquid is filtered, recover methanol through decompression, add volume percentage concentration and be 30% hydrochloric acid 30 times the amount, heated and hydrolyzed at 90°C for 4 hours, then filtered out the precipitate, and the obtained precipitate was dried to obtain 200 grams of semi-finished products; The contents of acid and polygalagenin are 32% and 50% respectively.

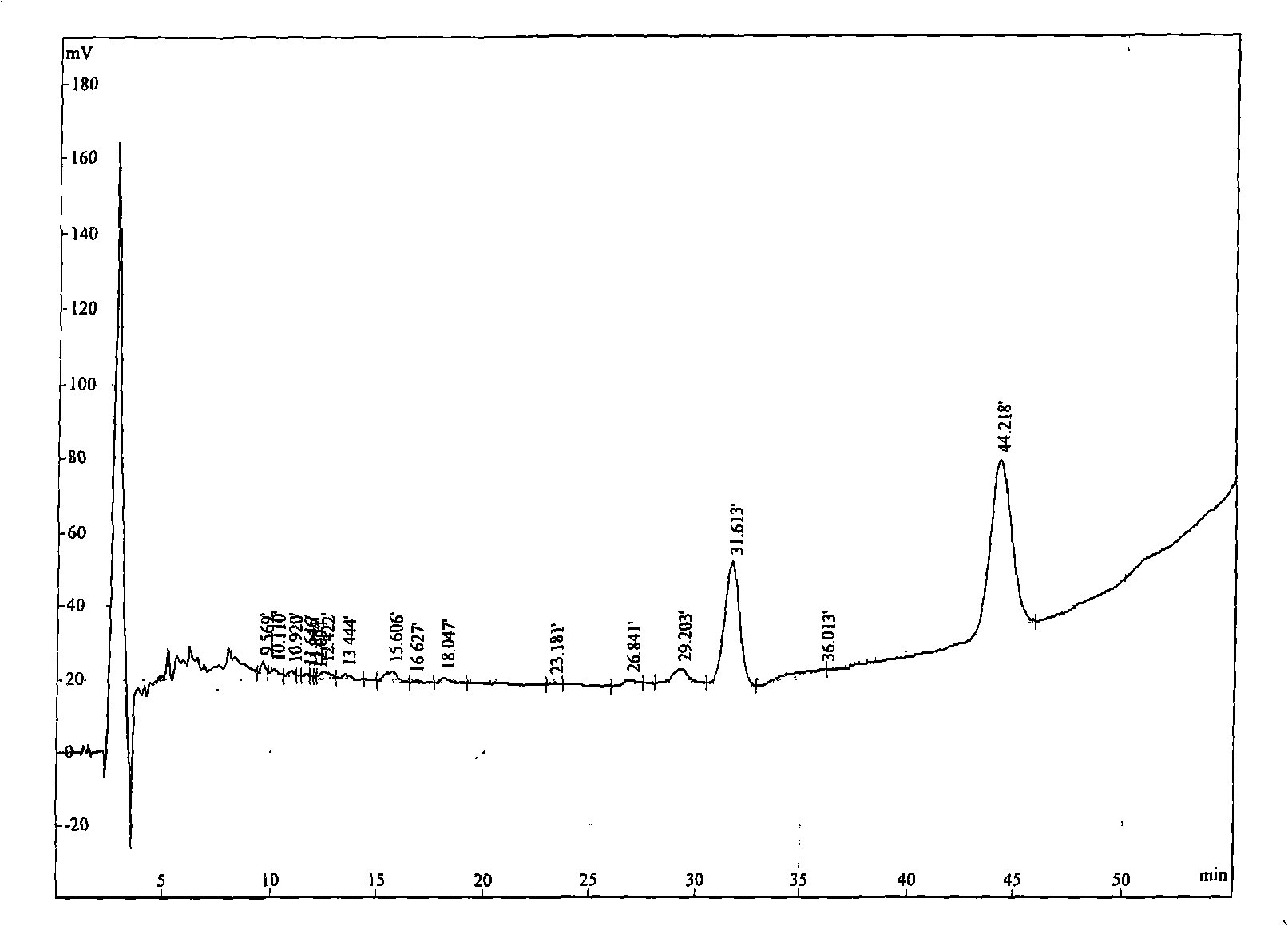

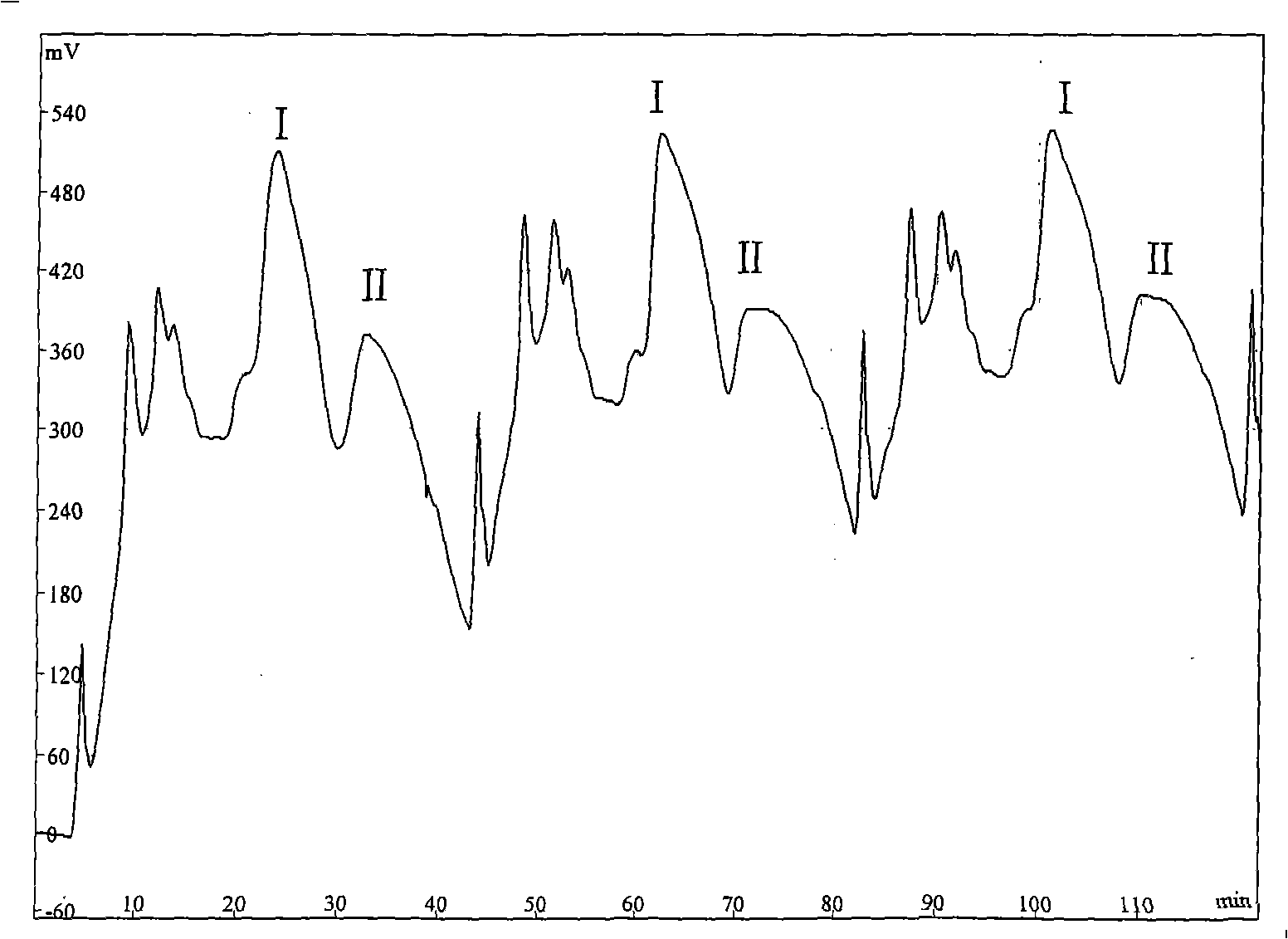

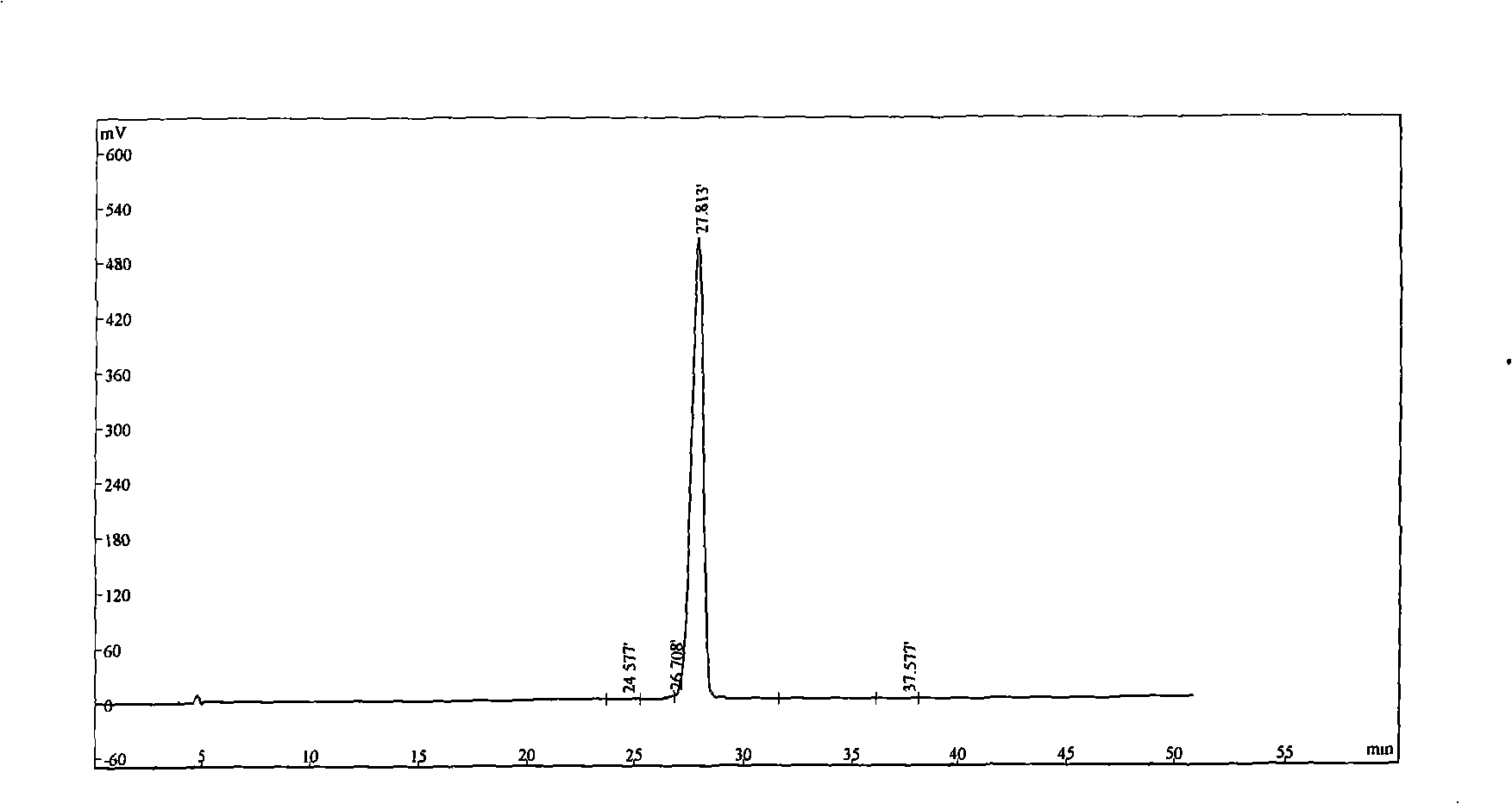

[0028] The chromatographic condition of described analytical high performance liquid chromatograph is: chromatographic column: octadecyl bonded silica gel (4.6 * 250mm, 5 μ m); Mobile phase: tetrahydrofuran-water-...

Embodiment 2

[0033] A method for separating and purifying polygalaic acid and polygalagenin, characterized in that it is carried out according to the following process steps:

[0034] A, the preparation of semi-finished products: take 10 kilograms of the original medicinal material of polygala, add 50 liters of volume percentage concentration and be 80% methanol solution reflux extraction, after extracting liquid is filtered, recover methanol through decompression, add volume percentage concentration and be 20% hydrochloric acid 20 times the amount, heated and hydrolyzed at 100°C for 2 hours, then filtered out the precipitate, and the obtained precipitate was dried to obtain 190 grams of semi-finished products; The contents of acid and polygalagenin were 34% and 52% respectively.

[0035] The chromatographic condition of described analytical high performance liquid chromatograph is: chromatographic column: octadecyl bonded silica gel (4.6 * 250mm, 5 μ m); Mobile phase: tetrahydrofuran-wate...

Embodiment 3

[0040] A method for separating and purifying polygalaic acid and polygalagenin, characterized in that it is carried out according to the following process steps:

[0041] A, the preparation of semi-finished products: take 10 kilograms of the original medicinal material of polygala, add 100 liters of volume percentage concentration and be 95% methanol solution reflux extraction, after extracting liquid is filtered, recover methanol through decompression, add volume percentage concentration and be 10% hydrochloric acid 10 times the amount, heated and hydrolyzed at 80°C for 3 hours, then filtered out the precipitate, and the obtained precipitate was dried to obtain 180 grams of semi-finished products; the polygala The contents of acid and polygalagenin are 35% and 51% respectively.

[0042] The chromatographic condition of described analytical high performance liquid chromatograph is: chromatographic column: octadecyl bonded silica gel (4.6 * 250mm, 5 μ m); Mobile phase: tetrahyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com