Ethene homopolymerization and copolymerization catalyst and preparation method thereof

A technology for ethylene polymerization and copolymerization, applied in the field of solid titanium catalysts, can solve the problems of low catalyst active components, poor catalyst activity, and difficulty in regulating particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

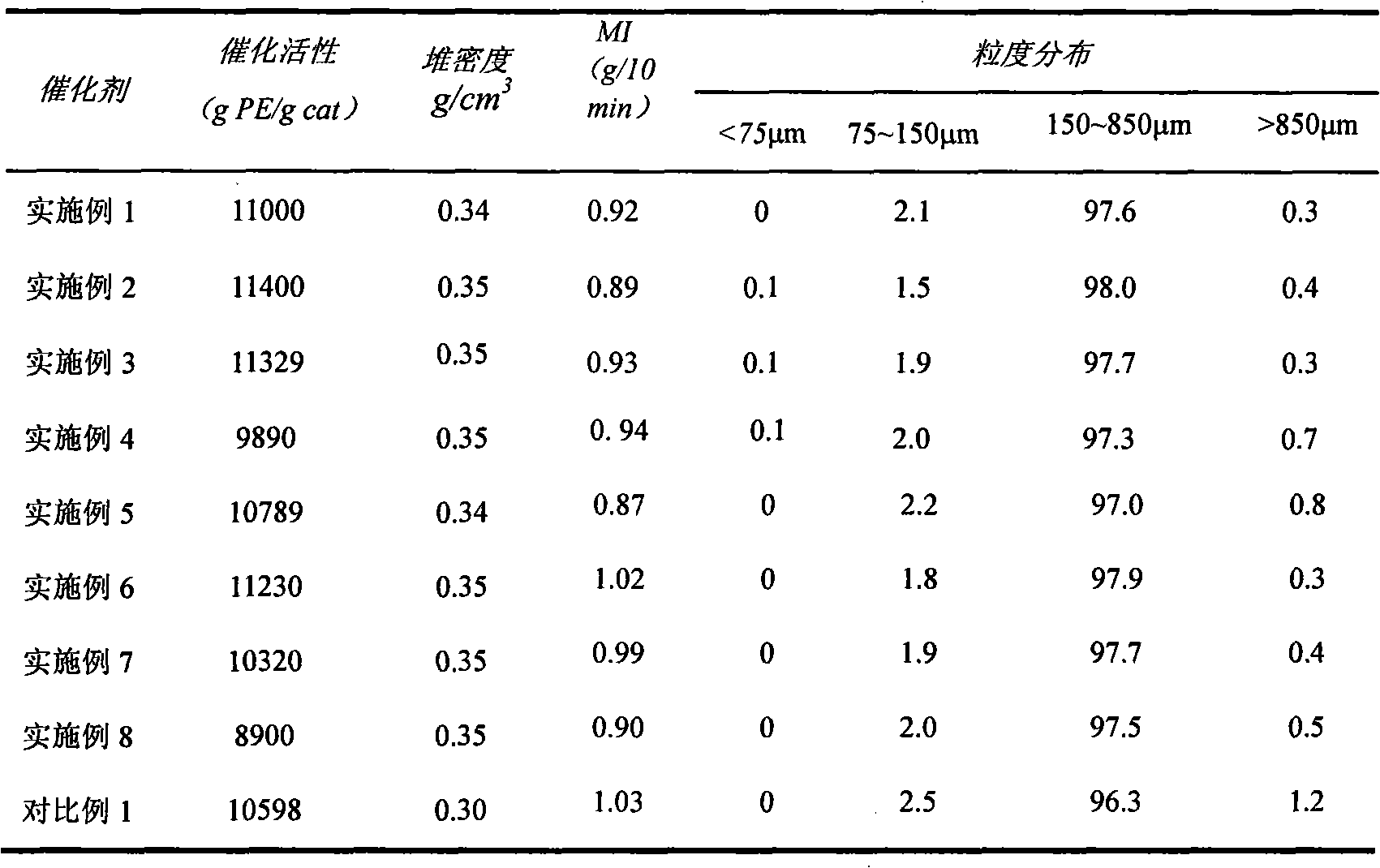

Examples

Embodiment 1

[0014]Example 1 4.76 grams (50 mmol) of anhydrous magnesium chloride, 90 milliliters of decane and 16.3 grams (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. To this solution was added 15 mmol of triethyl borate and stirred at 50° C. for 1 hour to dissolve triethyl borate in the solution. Add 10 grams of XPO2485 silica gel to the above solution, stir at 50°C for 1 hour, then cool the suspension obtained above to -10°C, then add 100 mL of titanium tetrachloride dropwise to the above solution within 1 hour while stirring in suspension. After completion of the dropwise addition, the temperature of the mixture was maintained at -10°C for 1 hour, then raised to 120°C over 3 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no precipita...

Embodiment 2

[0017] Example 2 4.76 grams (50 mmol) of anhydrous magnesium chloride, 90 milliliters of decane and 16.3 grams (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. Add 12 grams of XPO2485 silica gel to the above solution, stir at 50°C for 1 hour, then cool the suspension obtained above to -10°C, and then add 100 mL of titanium tetrachloride dropwise to the above solution within 1 hour while stirring. in suspension. After the dropwise completion, the temperature of the mixture was maintained at -10°C for 1 hour. Then 15 mmol of triethyl borate was added to the above mixture and stirred at -10°C for 1 hour to fully react the system. The temperature was then raised to 120°C over 3 hours with stirring and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no preci...

Embodiment 3

[0019] Example 3 4.76 grams (50 mmol) of anhydrous magnesium chloride, 90 milliliters of decane and 16.3 grams (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. To this solution, 7.5 mmol of triethyl borate was added and stirred at 50° C. for 1 hour to dissolve triethyl borate in the solution. Add 12 grams of XPO2485 silica gel to the above solution, stir at 50°C for 1 hour, then cool the suspension obtained above to -10°C, and then add 100 mL of titanium tetrachloride dropwise to the above solution within 1 hour while stirring. in suspension. After the dropwise completion, the temperature of the mixture was maintained at -10°C for 1 hour. Then 7.5 mmol of triethyl borate was added to the above mixture and stirred at -10°C for 1 hour to fully react the system. The temperature was then raised to 120°C over 3 hours with stirring and maintained at this temperature for 2 hours. After 2 hours of reaction, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com