Single-layer carbon nano-tube non-woven fabrics and preparation method thereof

A technology of single-layer carbon nanotubes and non-woven fabrics, which can be used in non-woven fabrics, textiles, papermaking, fiber processing, etc., and can solve problems such as low carbon conversion rate, limited carbon nanotubes excellent performance, and slow decomposition speed. , to achieve the effect of increasing mechanical properties, excellent mechanical properties, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

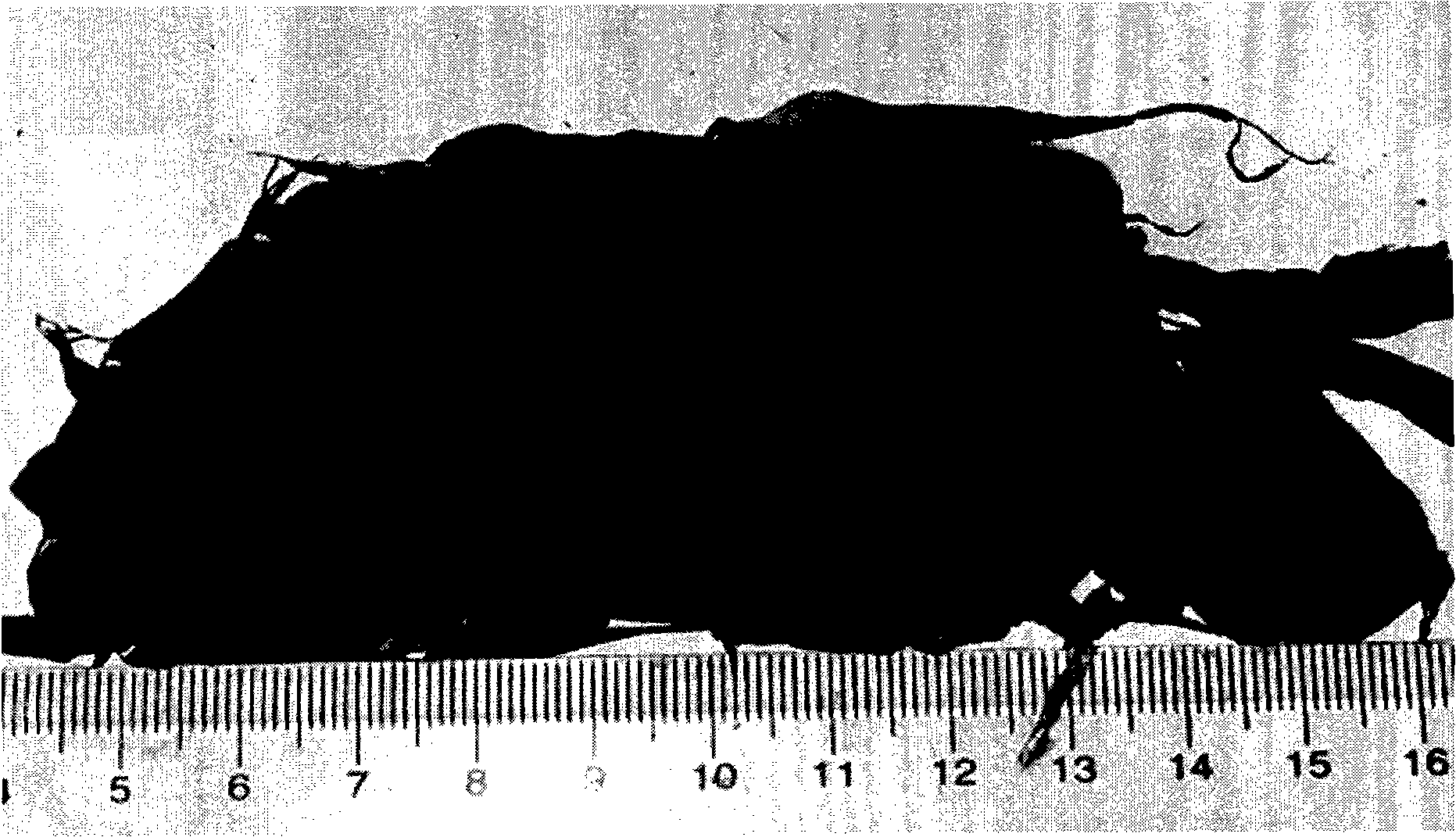

[0039] Example 1: Growth of original single-layer carbon nanotube nonwoven fabric

[0040] First design the following experimental device for preparing single-layer carbon nanotube non-woven fabrics by floating catalytic method:

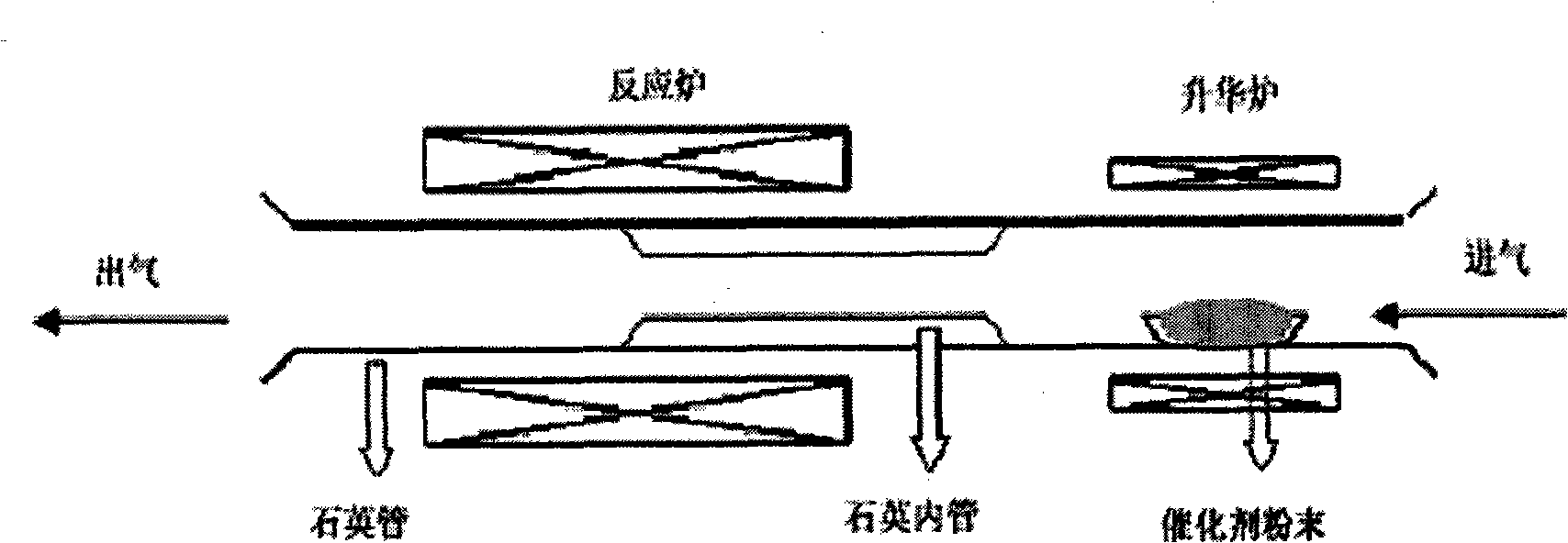

[0041] The schematic diagram of the equipment is as follows figure 1As shown, the experimental setup consists of two resistance furnaces with rated temperatures of 1250 °C and 300 °C, respectively. The reaction chamber used in the experiment is a quartz tube with a special structure, and its structure includes: the inner diameter of the outer large quartz tube is 30-40mm, and the length is 1-1.4m; the inner diameter of the small quartz tube inserted inside is 6-10mm, The length is 30-60cm. The port for the insert tubing is located throughout the middle of the reactor.

[0042] Then configure the following catalyst mixture:

[0043] Chemically pure ferrocene and sublimed sulfur were weighed and uniformly mixed at a molar ratio of 16:1, and ground ...

Embodiment 2

[0049] Embodiment 2: Purification of the original single-layer carbon nanotube non-woven fabric

[0050] The original single-layer carbon nanotube non-woven fabric prepared by the present invention is purified by gas-phase oxidation combined with concentrated hydrochloric acid immersion.

[0051] First, the original grown single-layer carbon nanotube non-woven fabric sample was placed in a resistance furnace at 350°C for oxidation, and kept in an air atmosphere for 48 hours; then the sample was placed in concentrated hydrochloric acid (concentration of 37%wt) Soak for one week; finally, the samples were removed from the hydrochloric acid and rinsed with deionized water until the pH value was 7.

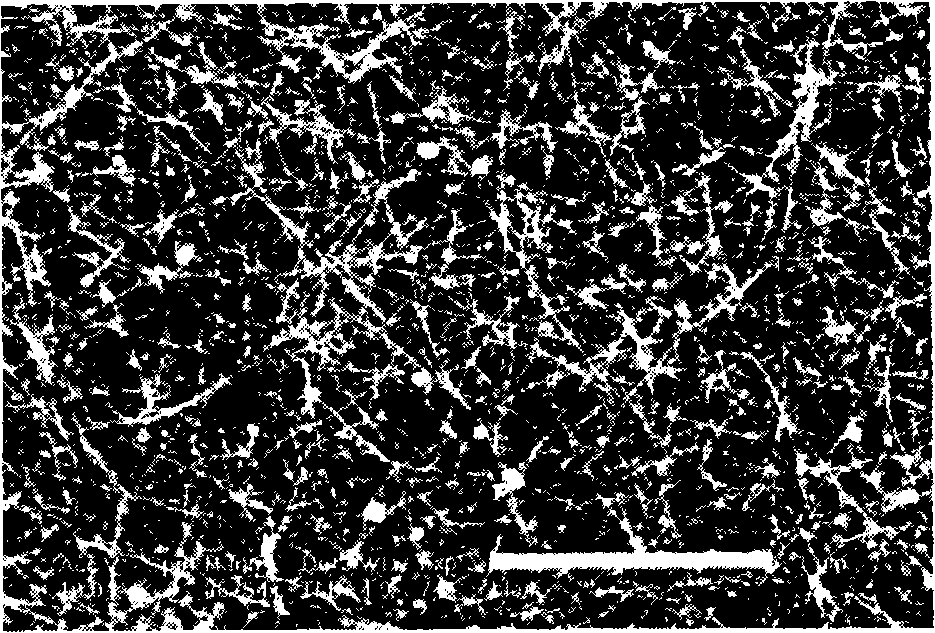

[0052] Figure 4a-Figure 4b It is a scanning electron microscope image of the plane and fracture of the purified single-layer carbon nanotube nonwoven fabric of the present invention. It can be seen from the figure that after the purification treatment, almost all the catalyst parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com