Sensing semiconductor and its making method

A technology of semiconductor and manufacturing method, which is applied in the field of sensing semiconductor devices, and can solve problems such as complex manufacturing process, high cost, and position deviation of inclined notches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention is described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

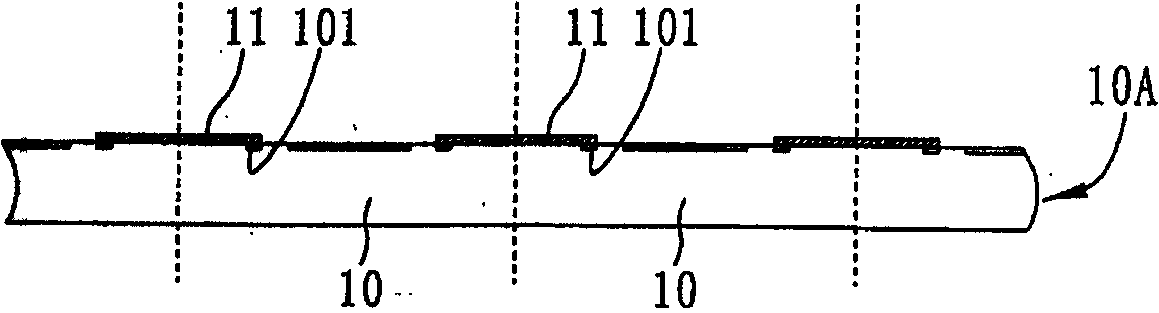

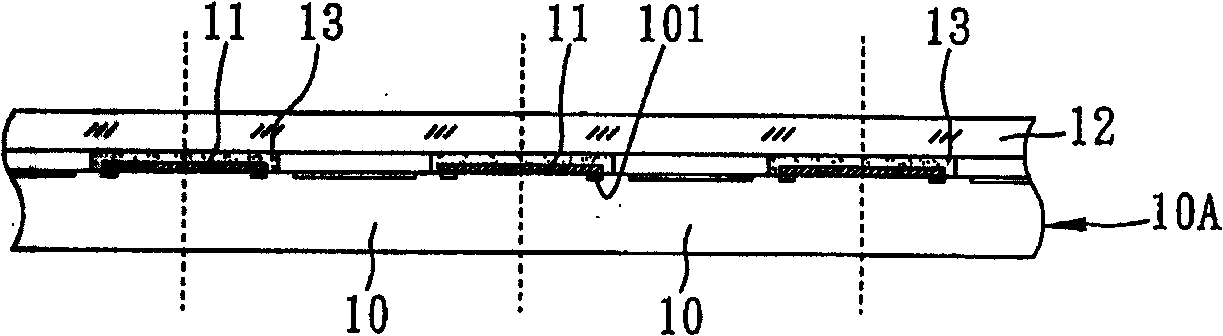

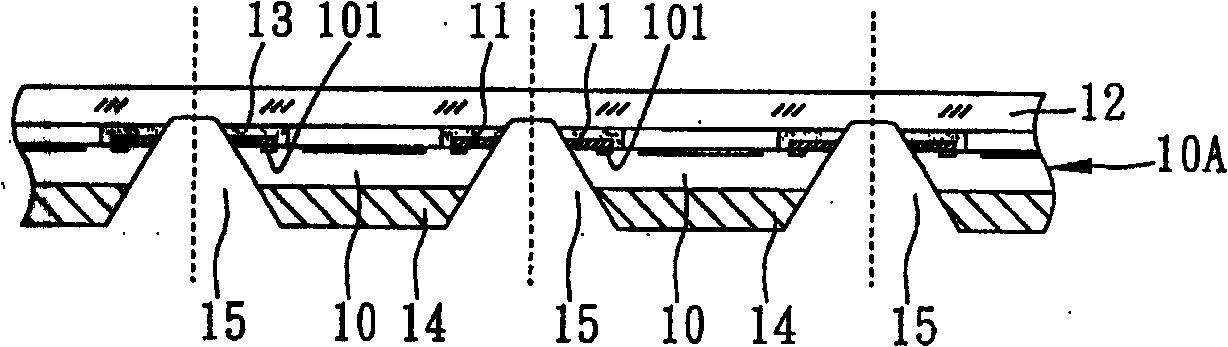

[0043] see Figure 2A to Figure 2I , is a schematic diagram of a first embodiment of the sensing semiconductor device and its manufacturing method of the present invention. In the following, the mass production of the sensing semiconductor device of the present invention will be taken as an illustration.

[0044] Such as Figure 2A As shown, a wafer 20A including a plurality of sensing chips 20 is provided. The sensing chip 20 has an active surface and a non-active surface opposite to each other. The active surface is provided with a sensing region 202 and a plurality of bonding pads 201, A plurality of grooves 203 are formed between the bonding pads 201 on the active surface of adjacent sensing chips 20 , wherein the grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com