Glass for shielding 2.45GHz electromagnetic wave and preparation method thereof

An electromagnetic wave and glass technology, which is applied in the field of glass shielding 2.45GHz electromagnetic wave and its preparation, can solve the problems of large volume, easy disconnection of grid points, and affecting product life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

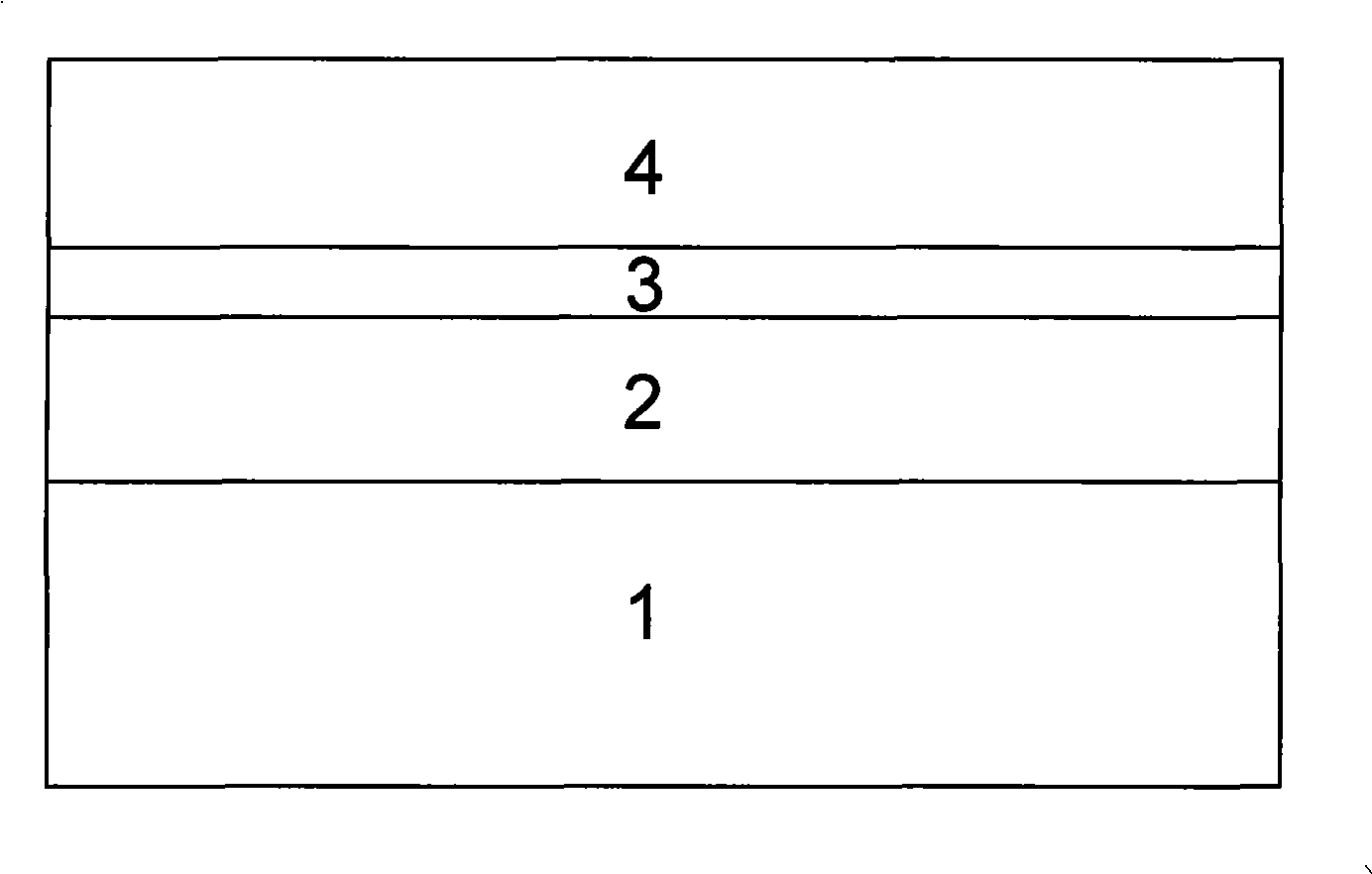

Image

Examples

Embodiment 1

[0019] 1) Use 3mm white glass as the coating substrate, first soak and clean it with a special glass cleaning solution, then place it in an acetone solution for ultrasonic vibration cleaning, then rinse it with deionized water, and finally dry it with clean hot air, put it into the electron beam evaporation studio, at 10 -5 Under Pa background vacuum, Ar gas was introduced, and the substrate surface was cleaned again by ion bombardment. The ion bombardment voltage was 1.4kV, the bombardment current was 90mA, and the bombardment time was 10min.

[0020] 2) Heating the substrate temperature to 100°C, evaporating a zinc sulfide film on the substrate by electron beam evaporation, and controlling the vacuum degree of the working room to 1.6×10 -3 Pa, beam current 10mA, deposition rate 9 Å / s:

[0021] 3) Turn off the heating device in the working room, and after cooling to room temperature, use electron beam evaporation to evaporate the metal silver film, and control the vacuum deg...

Embodiment 2

[0025] 1) Use 3mm white glass as the coating substrate, first soak and clean it with a special glass cleaning solution, then place it in an acetone solution for ultrasonic vibration cleaning, then rinse it with deionized water, and finally dry it with clean hot air, put it into the electron beam evaporation studio, at 10 -5 Under Pa background vacuum, Ar gas was introduced, and the substrate surface was cleaned again by ion bombardment. The ion bombardment voltage was 2.5kV, the bombardment current was 180mA, and the bombardment time was 16min.

[0026] 2) Heating the substrate temperature to 100°C, evaporating a zinc sulfide film on the substrate by electron beam evaporation, and controlling the vacuum degree of the working room to 2.5×10 -3 Pa, beam current 40mA, deposition rate 9 angstroms / second;

[0027] 3) Turn off the heating device in the working room, and after cooling to room temperature, use electron beam evaporation to evaporate and deposit metallic silver film, a...

Embodiment 3

[0031] 1) Use 3mm white glass as the coating substrate, first soak and clean it with a special glass cleaning solution, then place it in an acetone solution for ultrasonic vibration cleaning, then rinse it with deionized water, and finally dry it with clean hot air, put it into the electron beam evaporation studio, at 10 -5 Under Pa background vacuum, Ar gas was introduced, and the substrate surface was cleaned again by ion bombardment. The ion bombardment voltage was 2.0kV, the bombardment current was 120mA, and the bombardment time was 13min.

[0032] 2) Heating the substrate temperature to 100°C, evaporating a zinc sulfide film on the substrate by electron beam evaporation, and controlling the vacuum degree of the working room to 2.0×10 -3 Pa, beam current 20mA, deposition rate 6 angstroms / second;

[0033] 3) Turn off the heating device in the working room, and after cooling to room temperature, use electron beam evaporation to evaporate the metal silver film, and control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com