Technique for extracting cynamorlum herba cistanches medicinal materials effective component

An extraction process and technology of Cistanche deserticola, applied in the directions of medical preparations containing active ingredients, organic chemistry, pharmaceutical formulations, etc., can solve the problems of waste and neglect of resources, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

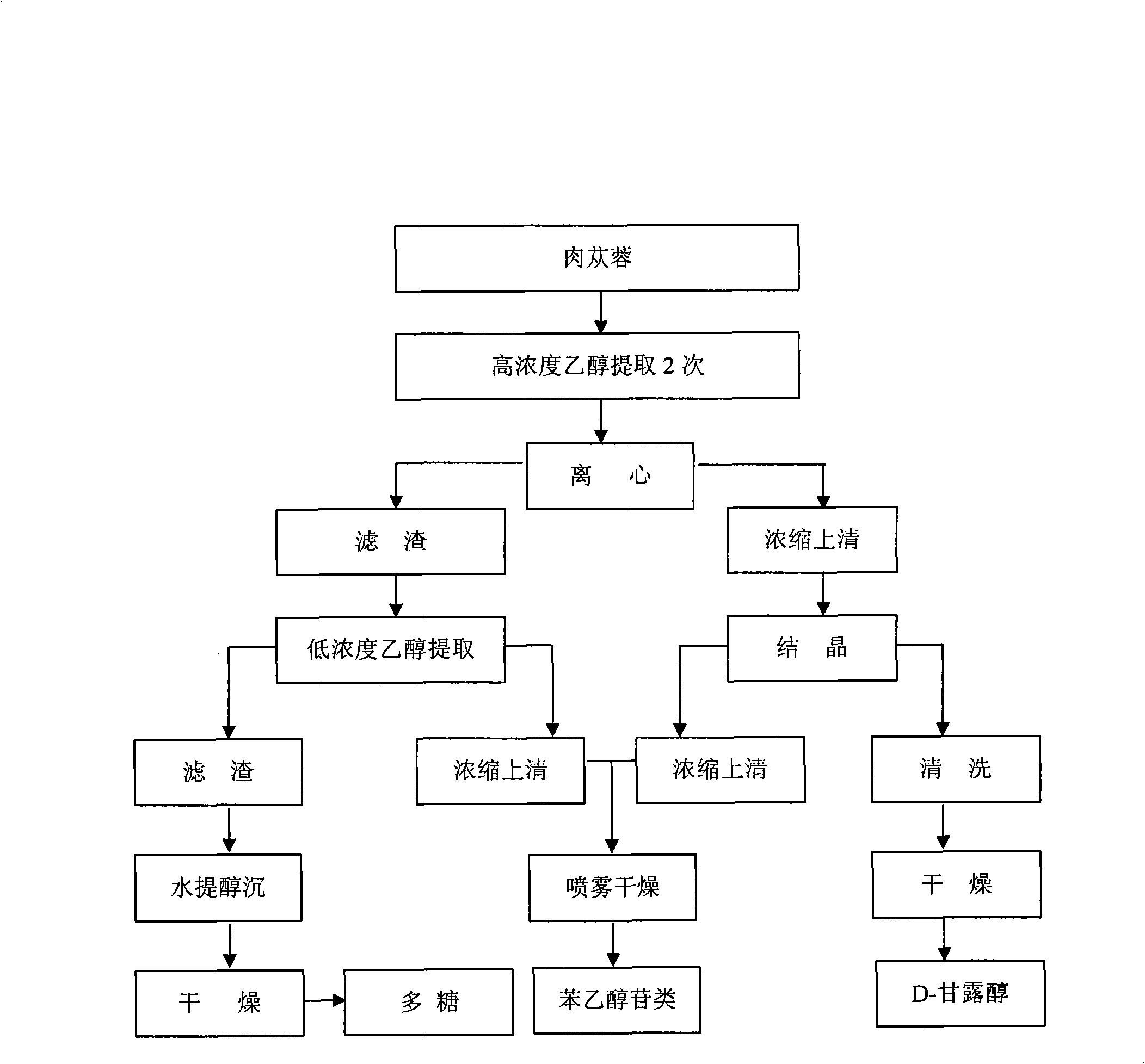

Method used

Image

Examples

Embodiment 1

[0019] Cistanche powder 1kg, adding 10 times the amount of ethanol with a concentration of 90% (V / V), extracted for 2 hours, then extracted with 8 times the amount of 90% (V / V) ethanol, combined two extracts, concentrated under reduced pressure, Crystallized and dried to obtain 16 g of crystalline material with a D-mannitol content of 50%. The extraction residue was continued to be extracted twice with 80% (V / V) ethanol solution, and the extract was concentrated under reduced pressure and spray-dried to obtain 300 g of Cistanche deserticola alcohol extract, containing 5% of phenylethanol glycosides. Continue to add 10 times the amount of distilled water to the extraction residue, heat and extract twice, add 3 times the volume of 95% ethanol to the supernatant after concentration under reduced pressure for precipitation, let stand at 4°C for 24 hours, collect the precipitate after centrifugation, and dry it. 60g of Cistanche polysaccharide can be obtained with a purity of 75%. ...

Embodiment 2

[0021] Cistanche powder 1kg, add 10 times the amount of 95% (V / V) ethanol, extract for 2 hours, then extract with 8 times the amount of 95% (V / V) ethanol, combine the two extracts, concentrate under reduced pressure, crystallize, and dry 20 g of dried crystals were obtained, and the D-mannitol content was 64%. The extraction residue was continued to be extracted with 10 times the concentration of 80% (V / V) ethanol solution for 2 hours, and then extracted with 70% (V / V) ethanol solution for 2 hours, and the extract was concentrated under reduced pressure, Spray-dry to obtain 350 g of phenylethanol glycosides, and the content of phenylethanol glycosides is 7%. Continue to add 15 times the amount of distilled water to the extraction residue, heat and extract twice, add 3 times the volume of 95% ethanol to the supernatant after concentration under reduced pressure for precipitation, let it stand at 4°C for 24 hours, collect the precipitate after centrifugation, and dry it. 60g of...

Embodiment 3

[0023] Cistanche deserticola powder 1kg, add 8 times the amount of 90% (V / V) ethanol, extract 2 hours, extract twice, combine two extractions, concentrate under reduced pressure, crystallize, dry to obtain crystalline substance 10g, D-mannitol content is 50%. Extract the residue, continue to use 10 times the concentration of 70% (V / V) ethanol solution to carry out reflux extraction twice, the extract is passed through D101 macroporous resin, the eluate is collected, concentrated under reduced pressure, and spray-dried to obtain phenylethanol glycosides 10 g of a purified product with a content of 80%. Continue to add 15 times the amount of distilled water to the extraction residue, decoct and extract twice, add 3 times the volume of 95% ethanol to the supernatant after concentration under reduced pressure for precipitation, let stand at 4°C for 24 hours, collect the precipitate after centrifugation, and dry 70g of Cistanche polysaccharide can be obtained with a purity of 70%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com