Method and apparatus for distinguishing coal-burning boiler coal fines timely degree property

A coal-fired boiler, a timely technology, applied in the safety device, combustion method, combustion chamber and other directions of the combustion chamber, which can solve the problems of complex system and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

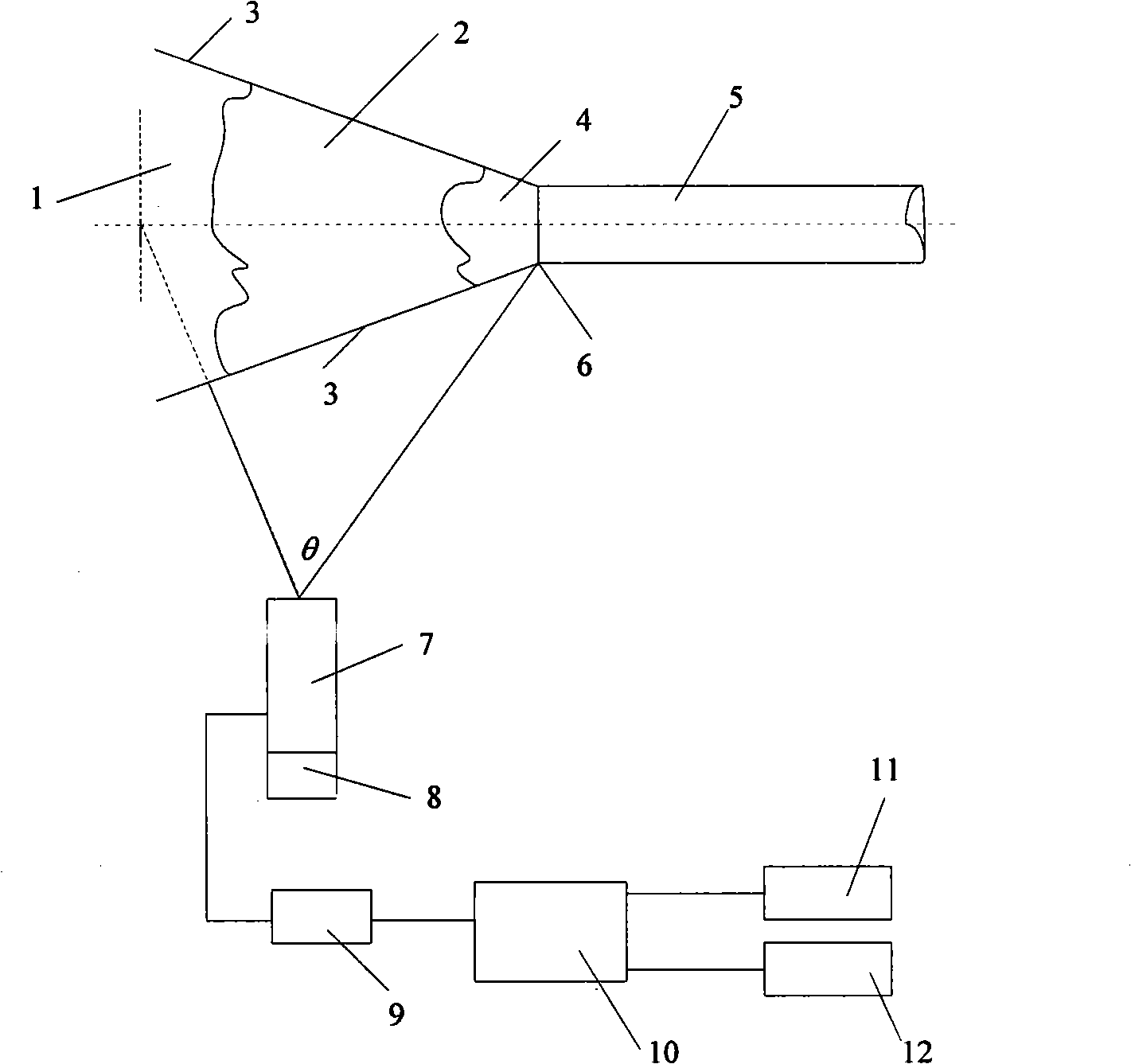

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

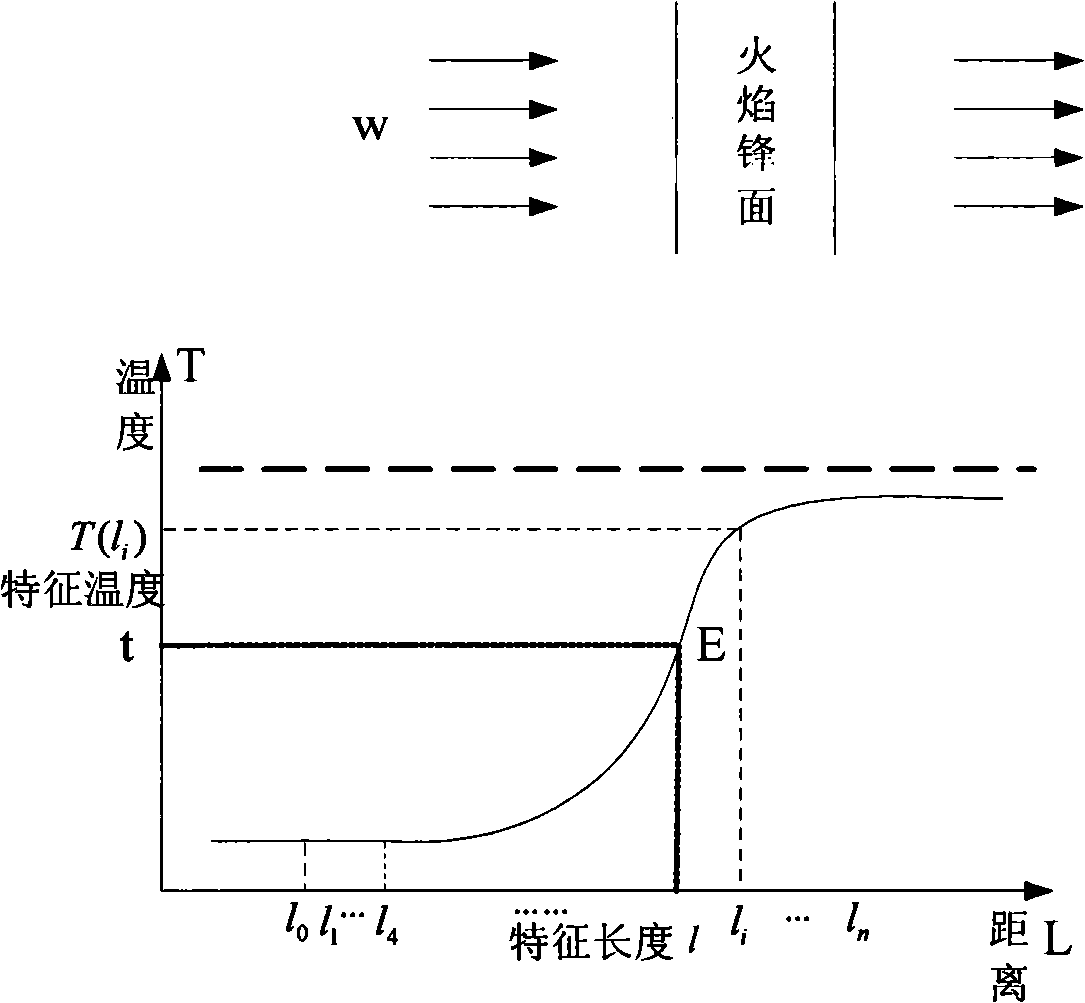

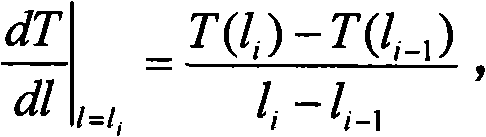

[0026] The principle of the present invention: the combustion process of the pulverized coal airflow in the boiler can basically be divided into three processes of ignition, combustion and burnout, and the three processes are always accompanied by two processes of heat absorption and heat release. After the pulverized coal flow is ejected from the nozzle, it first absorbs a certain amount of heat. During the process of absorbing heat, the temperature rises. After reaching the ignition temperature, it starts to ignite and burn, releasing a large amount of heat, and the temperature rises further. After reaching the energy balance, the temperature is stable. at a certain value. The pulverized coal airflow will form a flame after it starts to burn in a certain part. Through radiation, convection and heat conduction, the heat will be transferred to the fresh unbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com