SOG structure micro heat pipe and its manufacture method

A micro heat pipe and silicon wafer technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as limited heat transfer capacity, improve heat pipe performance, increase capillary driving force, improve performance and maximize heat transfer effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

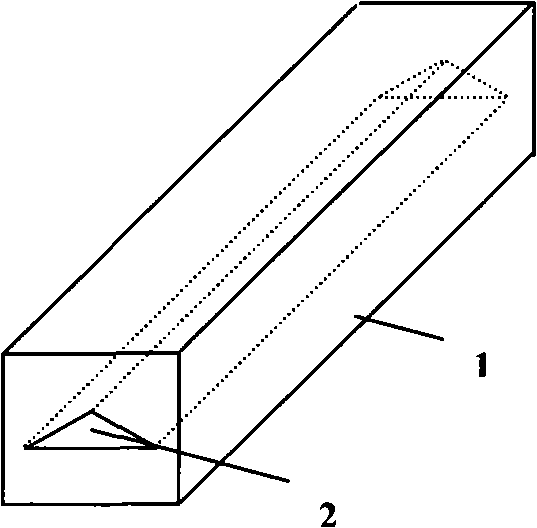

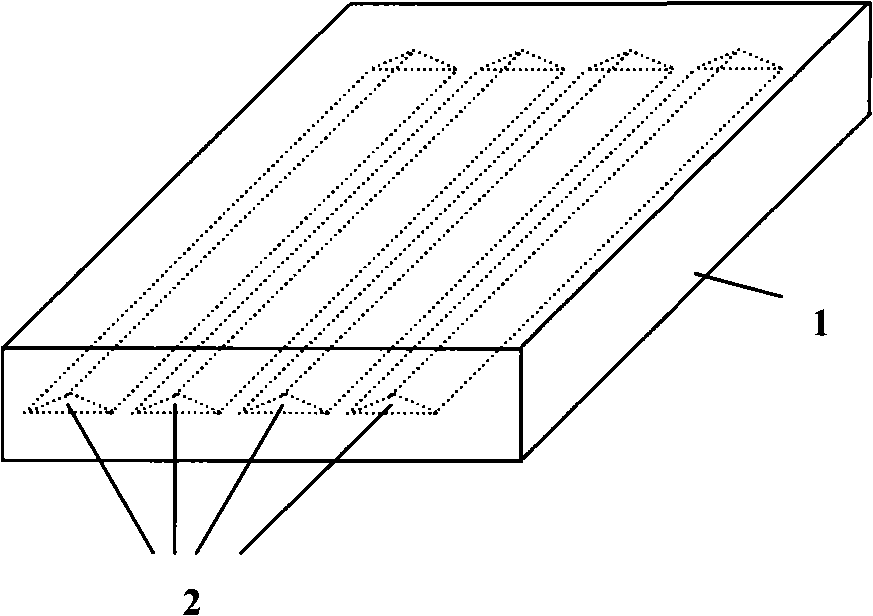

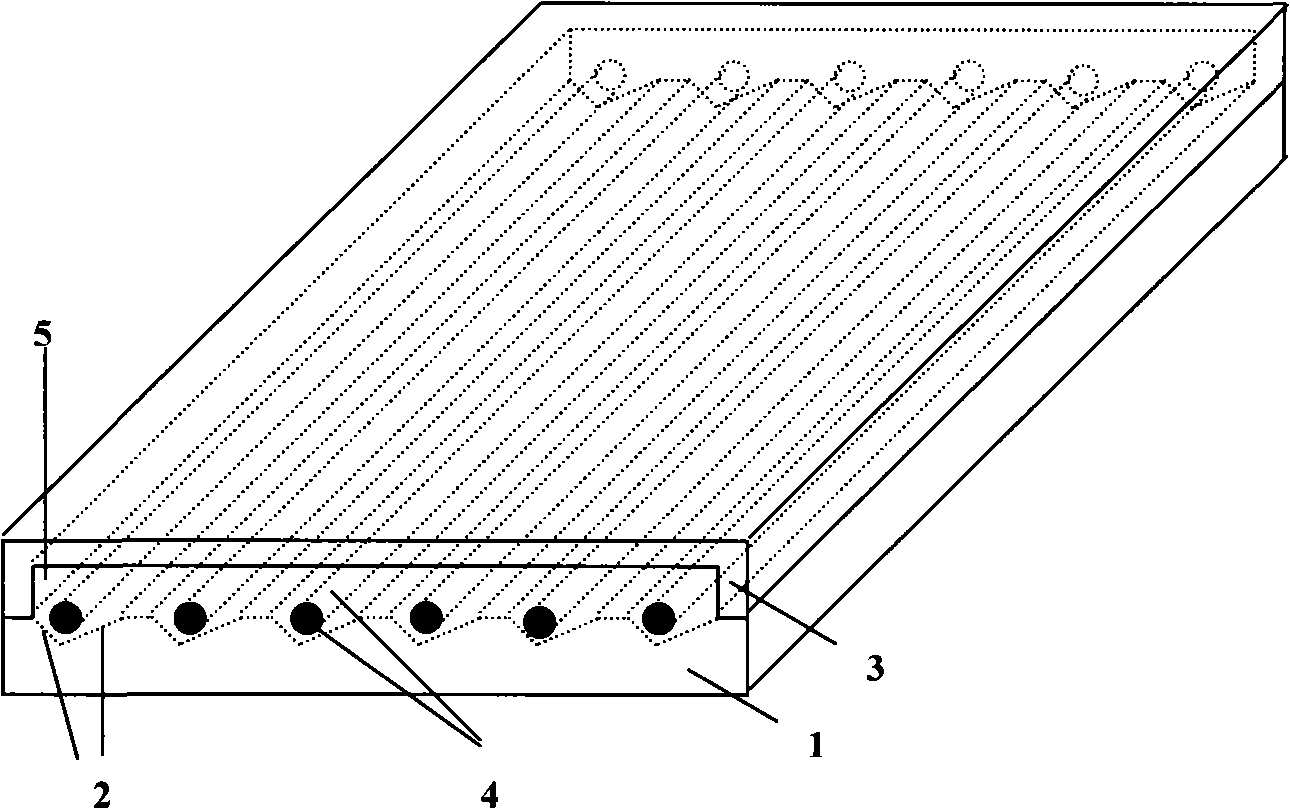

[0034] In the figure 1. Silicon wafer substrate; 2. Working fluid return groove; 3. Glass cover sheet; 4. Glass filament; 5. Connected steam chamber; 6. Liquid injection hole; 7. CPU; 8. SOG micro heat pipe; 9. Heat dissipation aluminum plate. combine image 3 , the composition of the SOG micro heat pipe in this embodiment includes three main parts: a silicon wafer substrate, a glass wafer and a glass filament; at the same time in conjunction with Figure 5, a series of parallel triangular grooves are etched on the substrate silicon wafer by anisotropic etching 2. The sharp corner area of the groove can provide capillary force for the backflow of the working fluid, and it is also a channel for the backflow of the working fluid. Put a straight glass filament in the groove 3. The existence of the glass filament can reduce the meniscus of the gas-liquid interface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com