Long period optical fibre grating ultraviolet laser point-to-point writing method

A fiber grating and ultraviolet laser technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of high cost, fixed grating wavelength, difficult to adapt to research, design and experiment, etc., and achieve the effect of saving production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

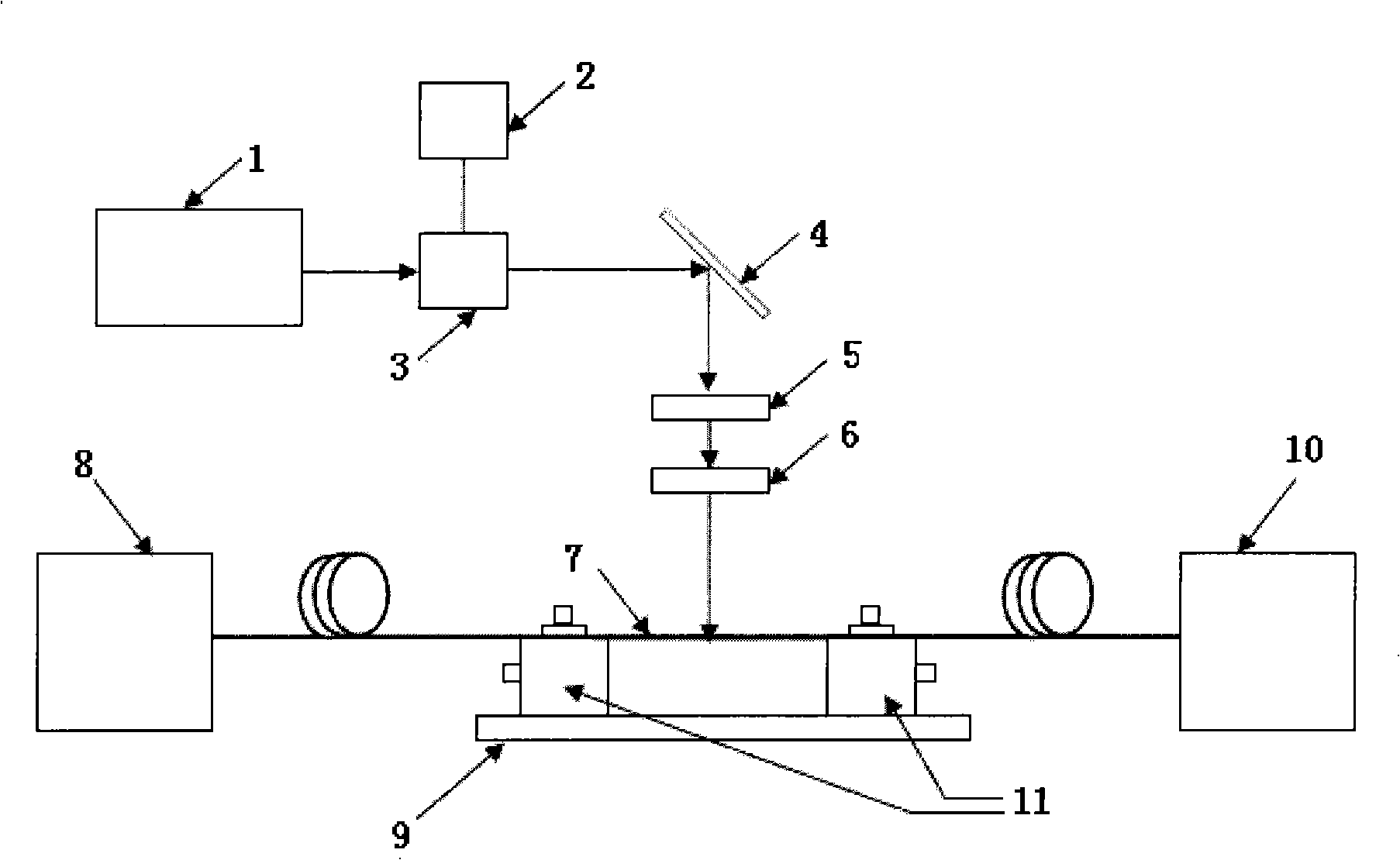

[0022] The embodiment device of the present invention such as figure 1 As shown, the model of laser 1 is Innova 300C Motofred (Coherent Company); the model of acousto-optic modulator 3 is M110-4UV(BR)-AT4 (GOOCH&HOUSEGO).

[0023] The ultraviolet laser point-by-point writing method of long-period fiber gratings, the steps are as follows:

[0024] I. Making optical path adjustment: the laser beam sent by laser 1 passes through AOM 3 and is reflected by plane mirror 4 again, and is vertically incident on the first cylindrical mirror 5 and the second cylindrical mirror 6 successively; the first cylindrical mirror 5 and the second cylindrical mirror Cylindrical mirrors 6 are placed orthogonally to each other, so that the laser beams form an energy-concentrated spot after being focused;

[0025] II. Determination of the position of the optical fiber: First clamp a test optical fiber in the V-shaped grooves of the optical fiber clamps 11 at both ends of the precision electronically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com