Rubber composition and tire made therefrom

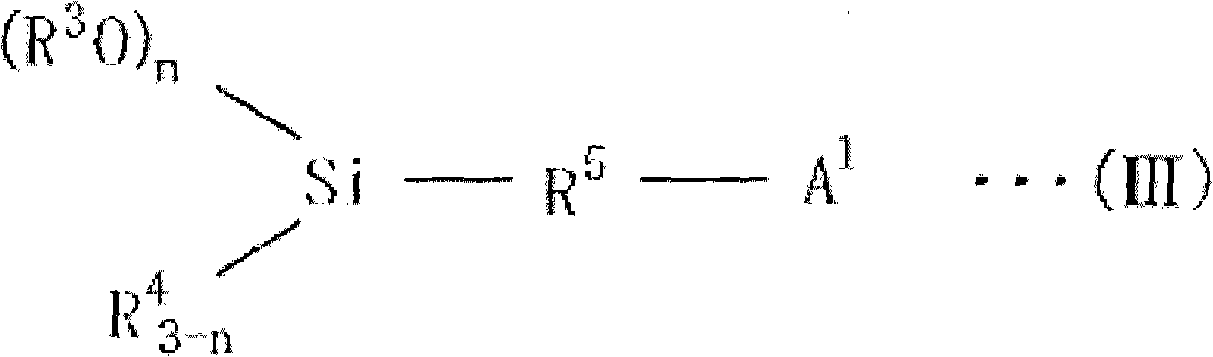

一种橡胶组合物、橡胶的技术,应用在特殊轮胎、轮胎零部件、运输和包装等方向,能够解决不能充分改善橡胶组合物加工性、不能充分体现填充剂分散性、低发热性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] (Manufacturing method of polymer A)

[0107] In a 800mL pressure-resistant glass container that was dried and replaced with nitrogen, 300g of cyclohexane, 40g of 1,3-butadiene, 10g of styrene, 0.2mmol of ditetrahydrofurylpropane were added, and n-butyllithium (n-BuLi ) 0.4 mmol, and then carry out polymerization reaction at 50° C. for 1.5 hours. The polymerization conversion rate at this time was almost 100%. Then, 0.5 mL of isopropanol solution (BHT concentration: 5% by mass) of 2,6-di-tert-butyl-p-cresol (BHT) was added to the polymerization reaction system to stop the polymerization reaction, followed by drying according to a common method. Polymer A is obtained.

[0108] (Manufacturing method of polymer B)

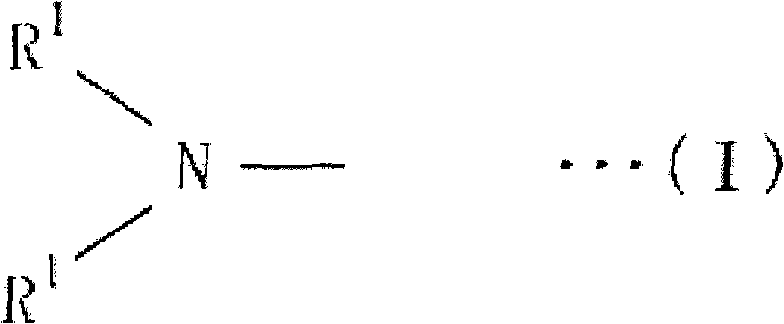

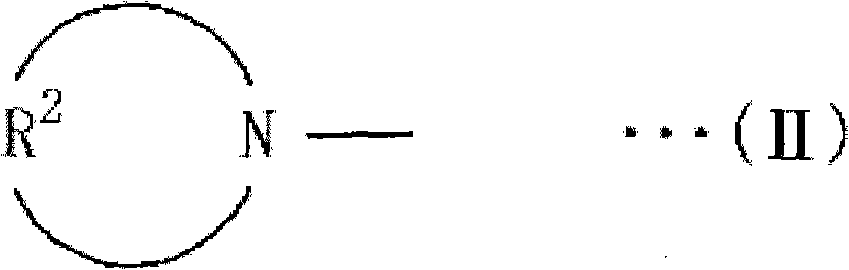

[0109] As a polymerization initiator, 0.48 mmol of in-situ prepared lithium hexamethyleneimide [HMI-Li: hexamethyleneimine (HMI) / lithium (Li) molar ratio = 0.9] was used in lithium equivalent, 0.48 mmol, Except for this, it carried out similarly to the said ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com