Process for preparing nano-SiO2/PET engineering plastic product

A technology of engineering plastics and production methods, applied in the direction of coating, etc., can solve problems that have not been reported before, and achieve the effects of wide application range, good quality of finished products, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

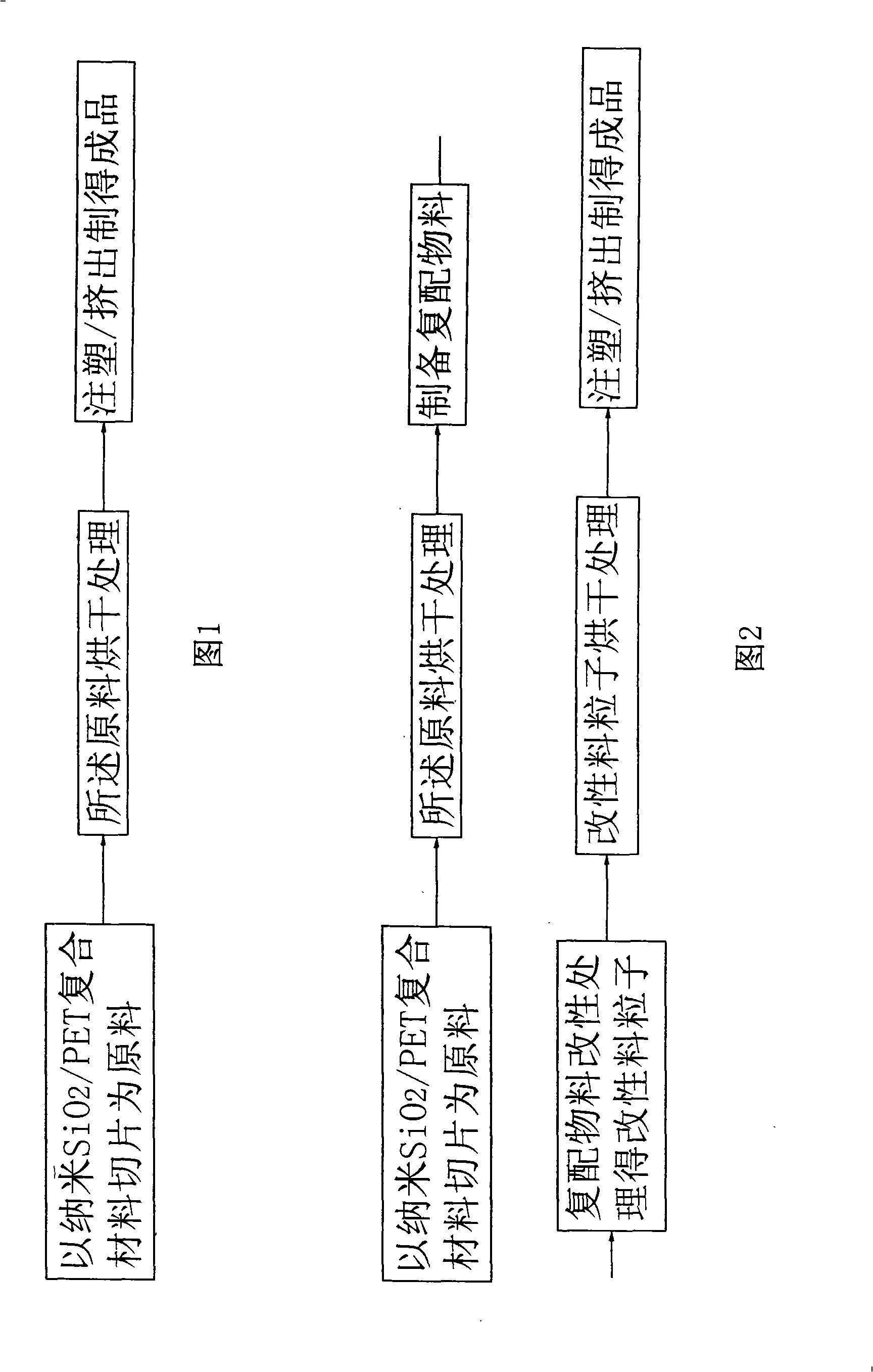

[0021] Embodiment 1, as shown in accompanying drawing 1. Preparation of nano-SiO 2 / PET engineering plastic products, such as plastic mechanical parts. Its production steps are:

[0022] (1) Raw material nano-SiO 2 / PET composite material drying treatment. The raw materials were placed in a hot air drying oven, dried at 150°C for 5 hours, and the moisture content was detected to be ≤40ppm, and they were taken out of the box for use.

[0023] (2) Molding. The dried nano-SiO 2 / PET composite material, put it into a screw injection molding machine, and adopt the usual PET injection molding process to obtain nano-SiO 2 / PET engineering plastic products.

Embodiment 2

[0024] Implementation 2, as shown in Figure 1. Preparation of nano-SiO 2 / PET plastic bar or plate. Its production steps are: except adopting screw extruder, others are all identical with implementation 1.

Embodiment 3

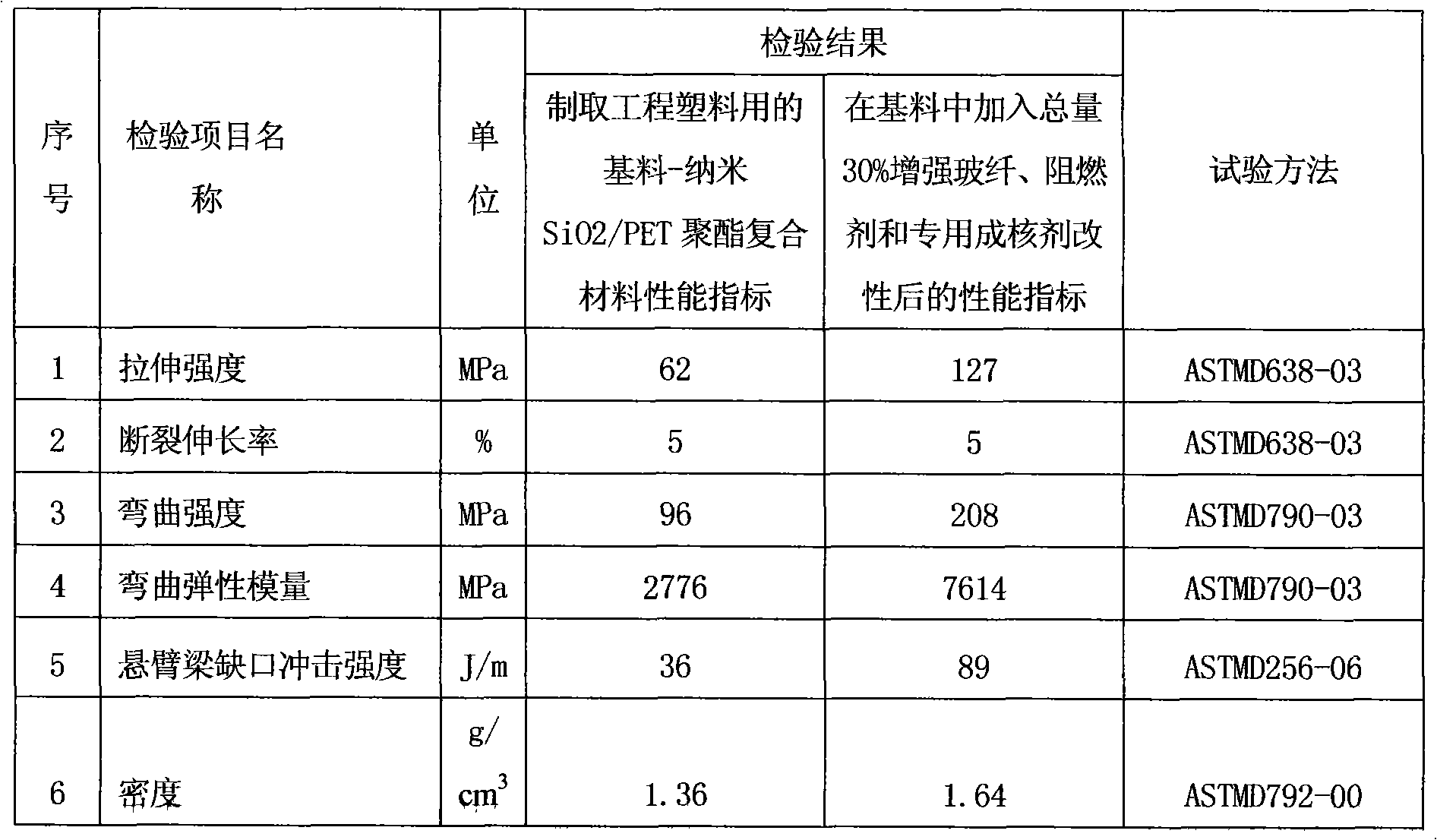

[0025] Implementation 3, refer to accompanying drawing 2. Preparation of Flame Retardant Nano-SiO 2 / PET engineering plastic products. Its production steps are:

[0026] (1) Raw material nano-SiO 2 / ET composite drying treatment. The raw materials were placed in a vacuum drying oven, dried at 135° C. for 6 hours, tested to have a moisture content of ≤ 40 pmm, and taken out of the box for use.

[0027] (2) Preparation of flame retardant. Take 3 parts by weight of decabromodiphenyl ether and 1 part by weight of antimony trioxide to compound to form a compound flame retardant.

[0028] (3) Preparation of compound materials. The dried nano-SiO prepared in the first step 2 / PET composite material, and the composite flame retardant prepared in the second step are weighed and compounded in a ratio of 100:5 by weight, and mixed into a composite material by uniform stirring; Dry at ℃ for 2 hours, and leave the box for use.

[0029] (4) Modification treatment. Put the compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com