Concentration method for sugar liquid in cellulose alcoholic fermentation

A technology of cellulosic ethanol and sugar liquid, which is applied in fermentation, pervaporation, biofuel and other directions to achieve the effect of reducing operating cost, compact equipment and short concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, a method for concentrating sugar liquid in cellulose ethanol fermentation, the following steps are carried out successively:

[0024] 1), membrane filtration (this is prior art):

[0025] The hydrolyzed sugar solution (concentration less than 2%) is filtered through a membrane to remove suspended particles.

[0026] 2), membrane distillation concentration:

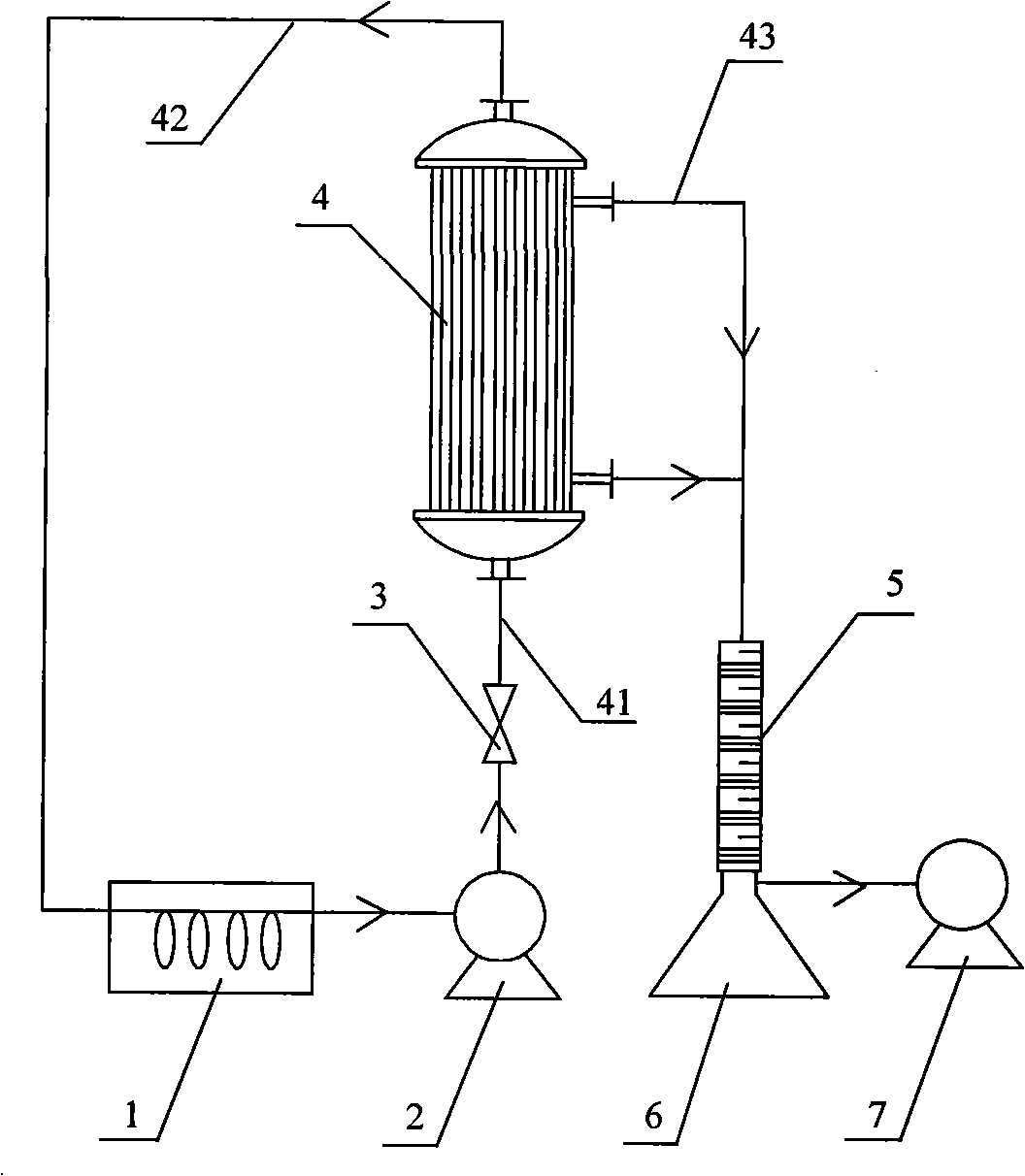

[0027] Devices used such as figure 1 As shown, it selects a single hydrophobic membrane module, and uses vacuum operation to realize the concentration of sugar solution, so all connections of the whole device must be kept sealed and connected.

[0028] Place the sugar solution after removing suspended particles in the feed liquid tank 1 with heating device, and the feed liquid tank 1 heats the sugar liquid to 50°C; under the action of the feed liquid pump 2, the sugar liquid passes through the control valve 3 and enters Feed pipe 41 is delivered to hydrophobic membrane assembly 4 (that is feed pipe ...

Embodiment 2

[0033] Embodiment 2, a method for concentrating sugar liquid in cellulose ethanol fermentation, the following steps are carried out successively:

[0034] 1), membrane filtration: with embodiment 1.

[0035] 2), membrane distillation concentration:

[0036] The feed liquid tank 1 heats the sugar solution to 70°C; the hydrophobic membrane module 4 can be a plate-and-frame module, and a hydrophobic microporous membrane made of polypropylene is selected. The pore diameter of the membrane is 0.1 μm, and the membrane area is about 0.2m 2 . Use the vacuum pump 7 to keep the vacuum on the right side of the membrane at 0.090Mpa, and the flux of the microporous membrane is about 4.5L / m at this time 2 h.

[0037] Embodiment 1 of the remaining contents.

[0038] The monosaccharide concentration in the finally obtained sugar solution reaches 20%. The concentration of monosaccharides in the water permeated from the microporous membrane is less than 0.01%.

Embodiment 3

[0039] Embodiment 3, a method for concentrating sugar liquid in cellulose ethanol fermentation, the following steps are carried out successively:

[0040] 1), membrane filtration: with embodiment 1.

[0041] 2), membrane distillation concentration:

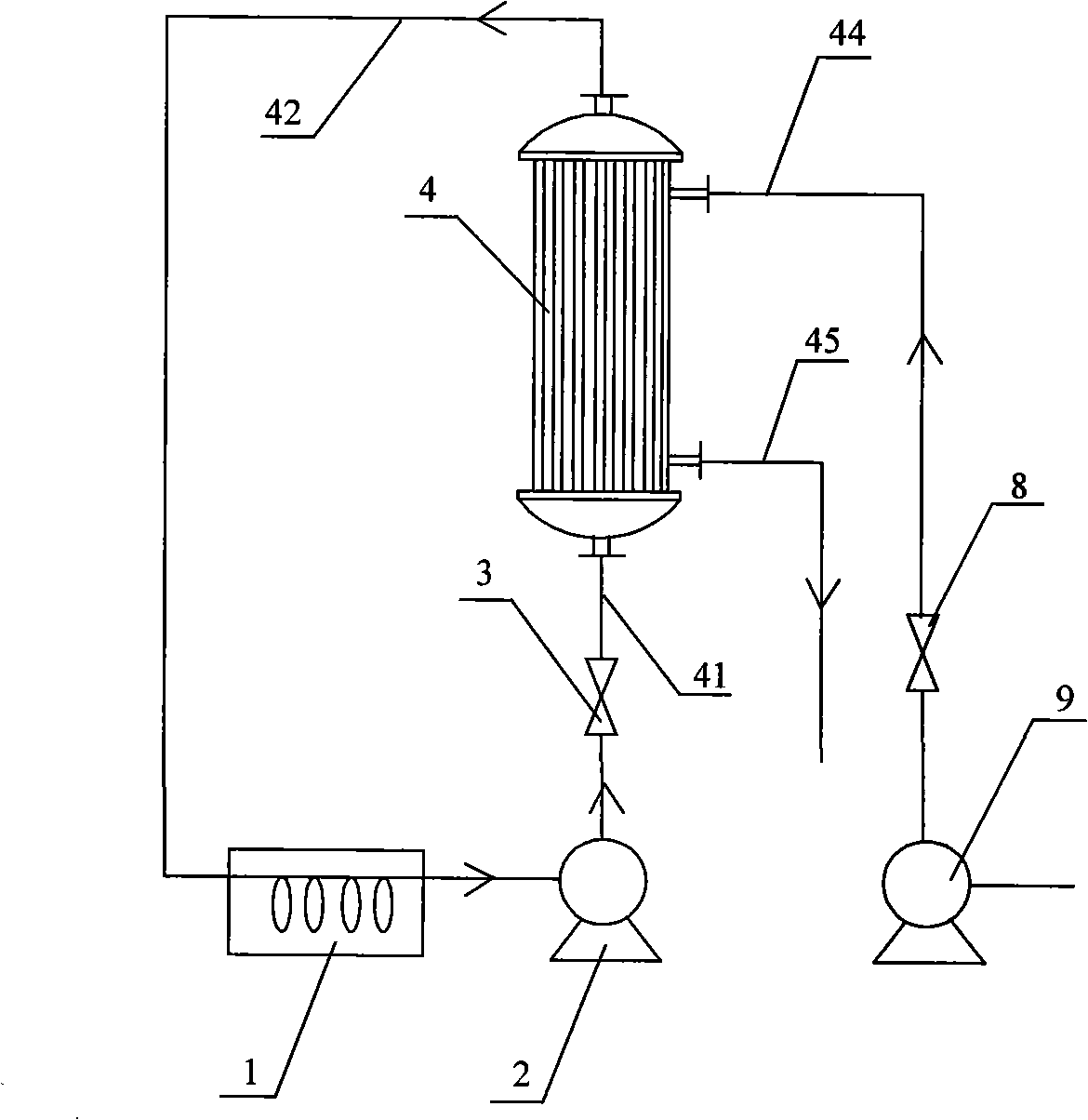

[0042] Devices used such as figure 2 As shown, it selects a single hydrophobic membrane module and realizes the concentration of sugar solution by direct contact operation.

[0043] Place the sugar solution after removing suspended particles in the feed liquid tank 1 with heating device, and the feed liquid tank 1 heats the sugar liquid to 50°C; under the action of the feed liquid pump 2, the sugar liquid passes through the control valve 3 and enters The feed pipe 41 is transported to the hydrophobic membrane module 4 (that is, the feed pipe 41 communicates with the lower end on the left side of the hydrophobic membrane module 4, and the sugar solution enters the left side of the microporous membrane) for direct contact membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com