Internal-burning type gas-heating machine

A heat engine and compressor technology, which is applied to the hot air variable capacity engine device, the open gas positive displacement engine plant, mechanical equipment, etc., can solve the problems of insufficient energy and low power, and achieve efficiency The effect of improving, high power transmission efficiency, and simple power transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

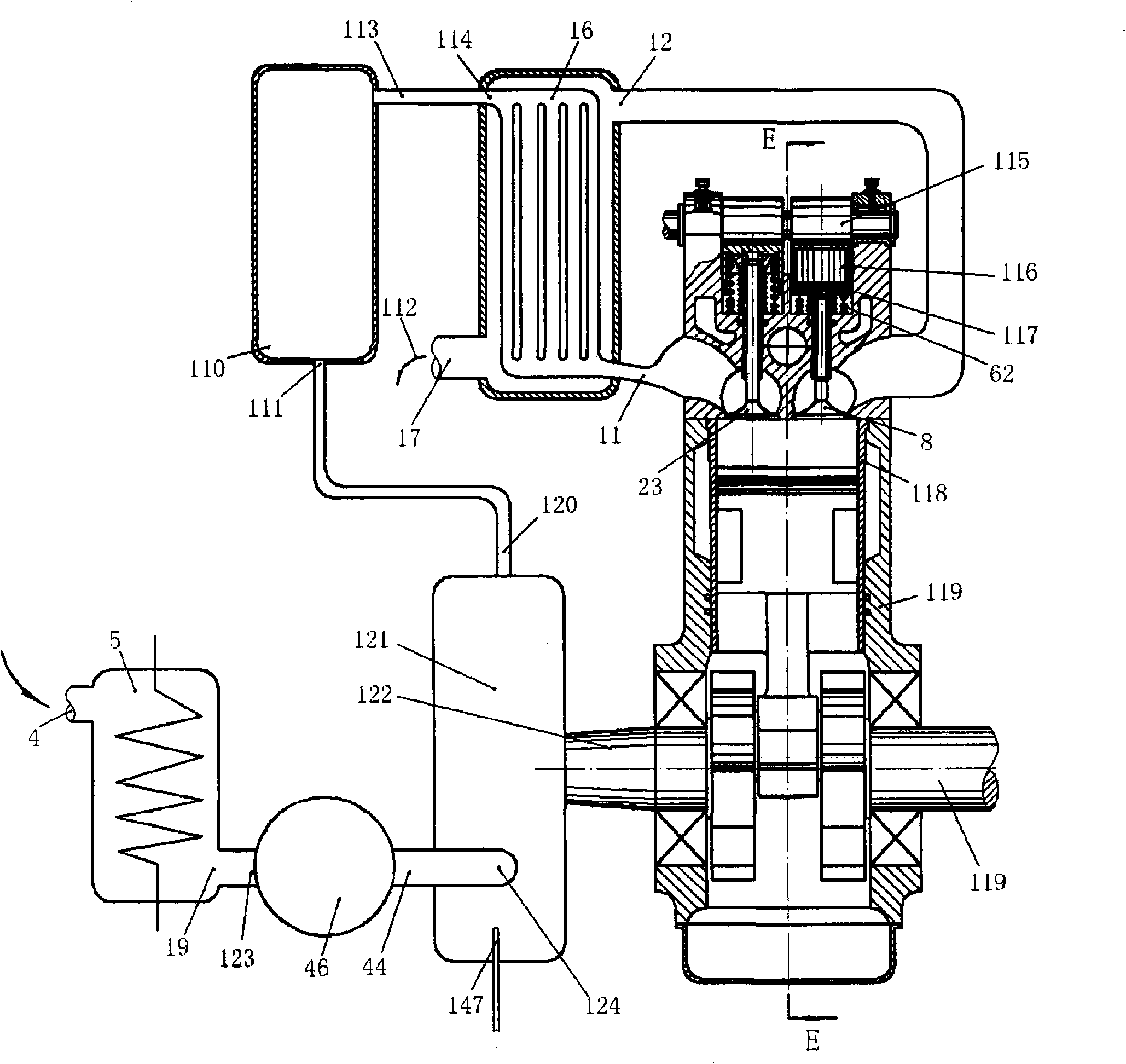

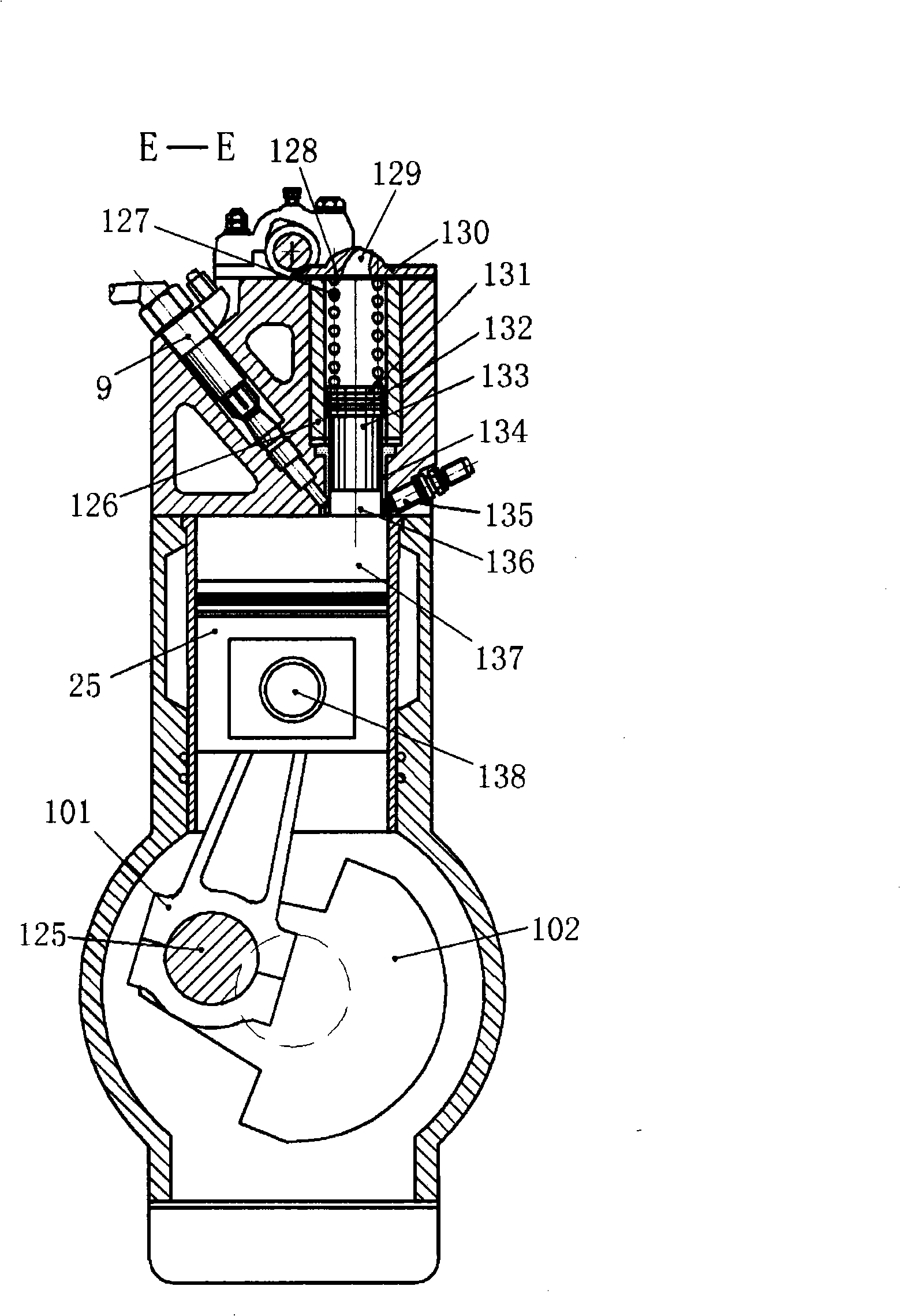

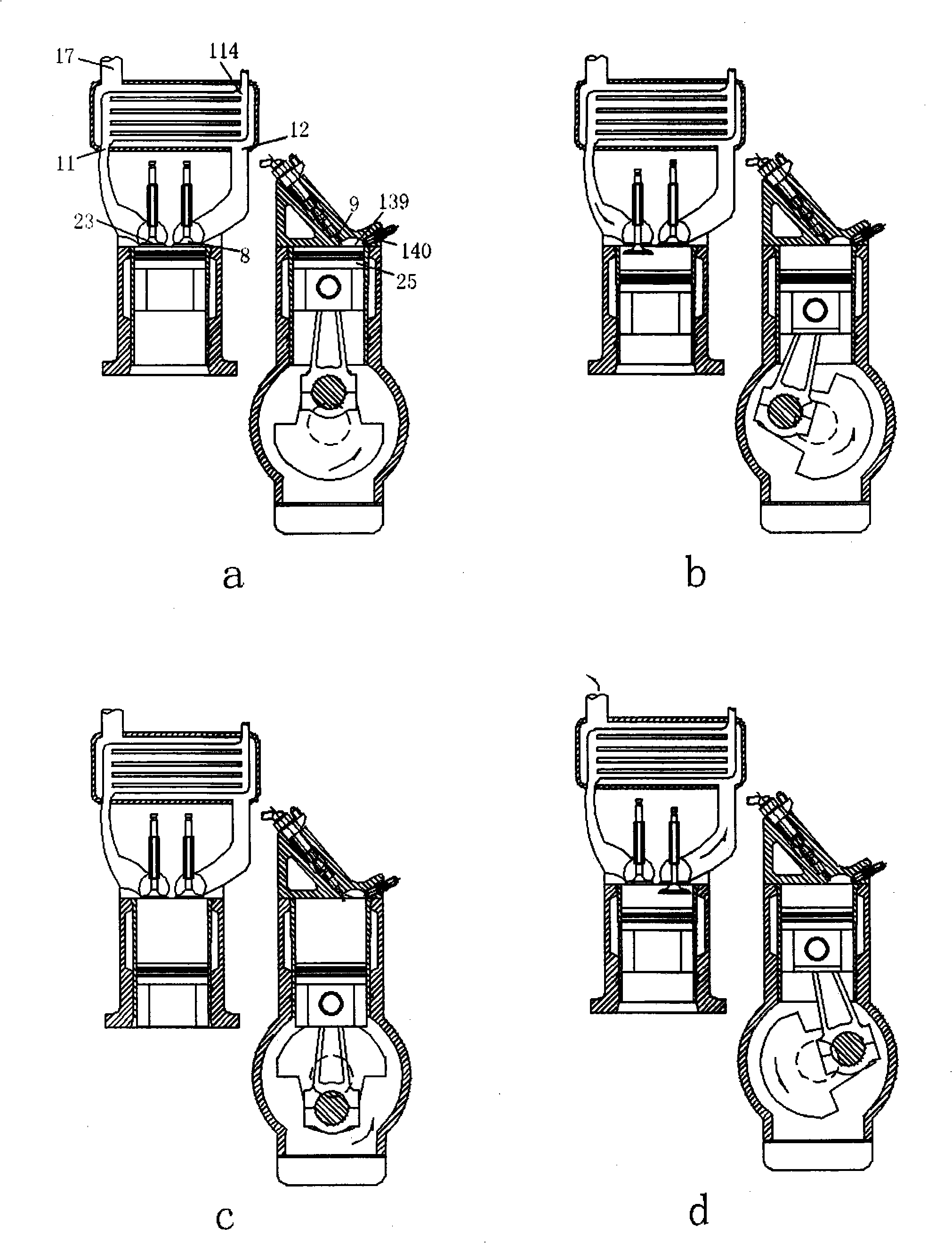

[0097] Depend on figure 1 As shown, the internal combustion type heat engine is mainly composed of a cylinder 118, a cylinder head 117, a compressor 121, a heat exchanger 16, a gas distribution mechanism, a power transmission mechanism and a heater. The gas distribution mechanism is arranged on the cylinder head, mainly Composed of intake valve 23, exhaust valve 8, camshaft 115, timing gear, etc., the cylinder is provided with a piston 25, and the piston, cylinder and cylinder head are sealed to form a cavity 137 whose volume changes with the movement of the piston. , the intake valve and exhaust valve arranged on the cylinder head are opened or closed regularly under the action of the camshaft, the piston is connected to the crank 102 through the piston connecting rod 101, and the power output shaft 122 of the crank is connected to the compressor 121 drive shaft connection. A variety of compressors can be used on internal combustion air heaters, such as reciprocating piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com