Quantum point-trap infrared detector structure and method for producing the same

A technology of infrared detectors and quantum dots, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low quantum efficiency of devices, large dark current, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

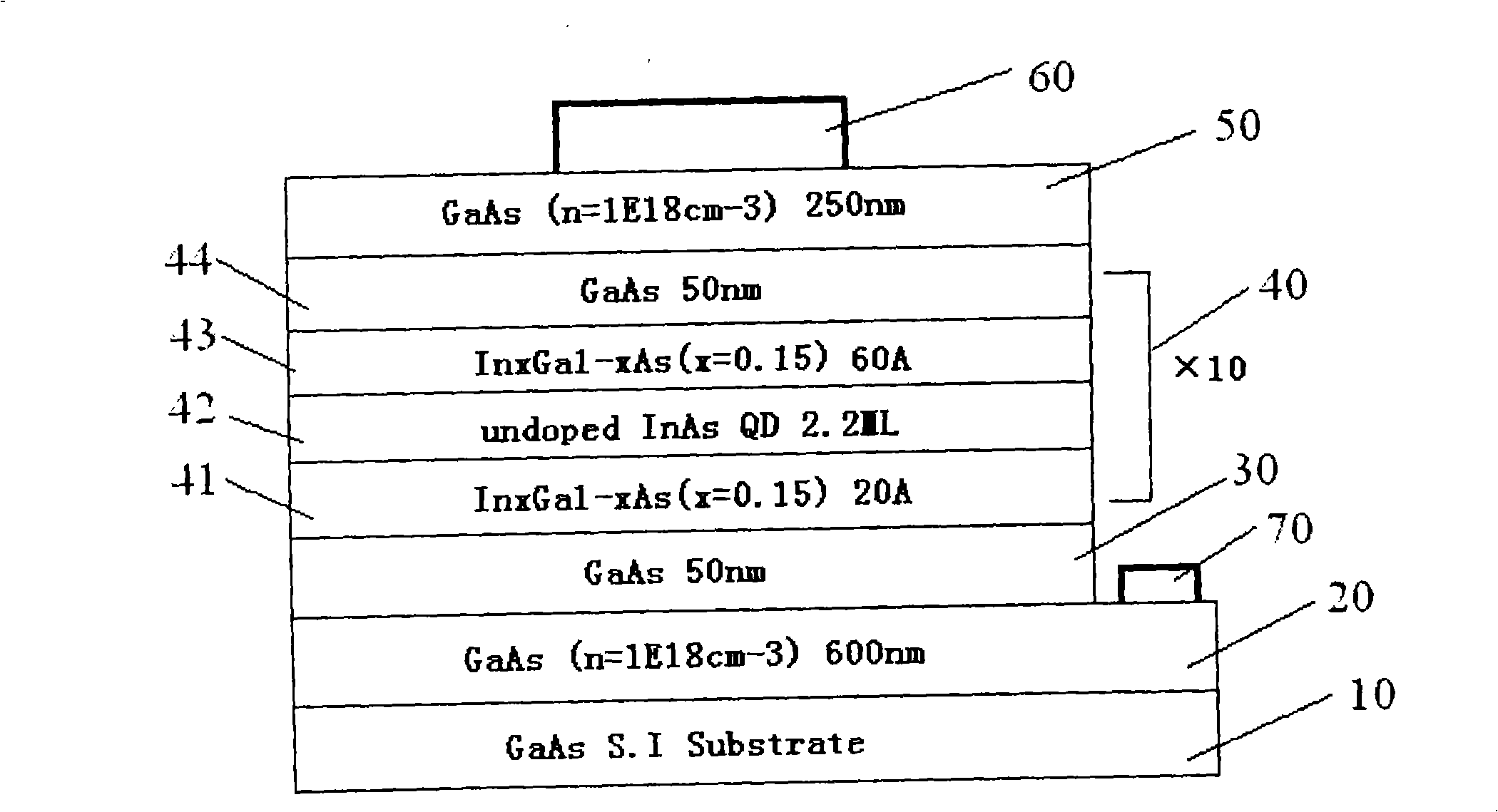

[0045] figure 1 It is the core idea of the present invention, that is, it is used in the growth process of the quantum dot-well structure infrared detector.

[0046] (1) First grow a highly doped GaAs bottom contact layer 20 on a semi-insulating GaAs substrate 10; the doping element is Si, and the doping concentration is 1×1018 / cm 3, the growth temperature is 580°C, and the thickness is 600nm. The purpose of doping the GaAs bottom contact layer 20 with a high concentration is to form a good ohmic contact with the electrode material AuGe / Ni / Au instead of a Schottky contact when the lower electrode 70 is fabricated later. The relatively thick 600nm growth is to facilitate the etching operation in the subsequent device manufacturing process;

[0047] (2) Then grow an undoped lower GaAs spacer layer 30 on the highly doped GaAs bottom contact layer 20 at a growth temperature of 580° C. and a thickness of 50 nm. The purpose of growing the undoped lower GaAs isolation layer 30 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com