Method for performing Yt-based heavy rare earth modification on high manganese steel

A technology of rare earth modification and high manganese steel, which is applied in the field of metal material modification, can solve the problems of wear, low yield strength of high manganese steel, easy deformation, etc., and achieve the effect of high cost performance and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Smelting: smelting scrap steel, adding ferromanganese, after the charge is completely melted, adding fluorite and quicklime to remove slag, and then inserting pure aluminum to remove oxygen, the insertion amount is 1.2Kg / ton steel.

[0023] (2), the addition of rare earth modifier

[0024] The yttrium-based heavy rare earth is baked, the baking temperature is 250° C., and the baking time is 8 minutes.

[0025] (3), pouring

[0026] The molten molten steel is flushed into the ladle, and the discharge temperature is 1410 °C, the molten steel is sedated for 10 minutes, and then poured, and the pouring temperature is 1400 °C.

[0027] (4), water toughness treatment

[0028] The castings are treated with water toughening, the temperature is 1060℃, the heat preservation is 90min, and the quality of the cooling water is 10 times that of the castings.

Embodiment 2

[0030] (1) Smelting: smelting scrap steel, adding ferromanganese, after the charge is completely melted, adding fluorite and quicklime to remove slag, and then inserting pure aluminum to remove oxygen, the insertion amount is 1.6Kg / ton steel.

[0031] (2), the addition of rare earth modifier

[0032] The yttrium-based heavy rare earth is baked at a baking temperature of 200°C and a baking time of 12 minutes. The baked rare earth is placed at the bottom of the ladle, the size of the rare earth is 12 mm, and the amount of rare earth added is 0.3%.

[0033] (3), pouring

[0034] The molten molten steel was flushed into the ladle, and the temperature was 1430°C, the molten steel was sedated for 12 minutes, and then poured at a temperature of 1425°C.

[0035] (4), water toughness treatment

[0036] The castings are treated with water toughening, the temperature is 1080℃, the holding time is 90min, and the quality of the cooling water is 15 times that of the castings.

Embodiment 3

[0038] (1) Smelting: smelting scrap steel, adding ferromanganese, after the charge is completely melted, adding fluorite and quicklime to remove slag, and then inserting pure aluminum to remove oxygen, the insertion amount is 1.8Kg / ton steel.

[0039] (2), the addition of rare earth modifier

[0040] The yttrium-based heavy rare earth is baked, the baking temperature is 150° C., and the baking time is 15 minutes.

[0041] (3), pouring

[0042] The molten molten steel is flushed into the ladle, and the temperature is 1460 °C, the molten steel is sedated for 15 minutes, and then poured, and the pouring temperature is 1450 °C.

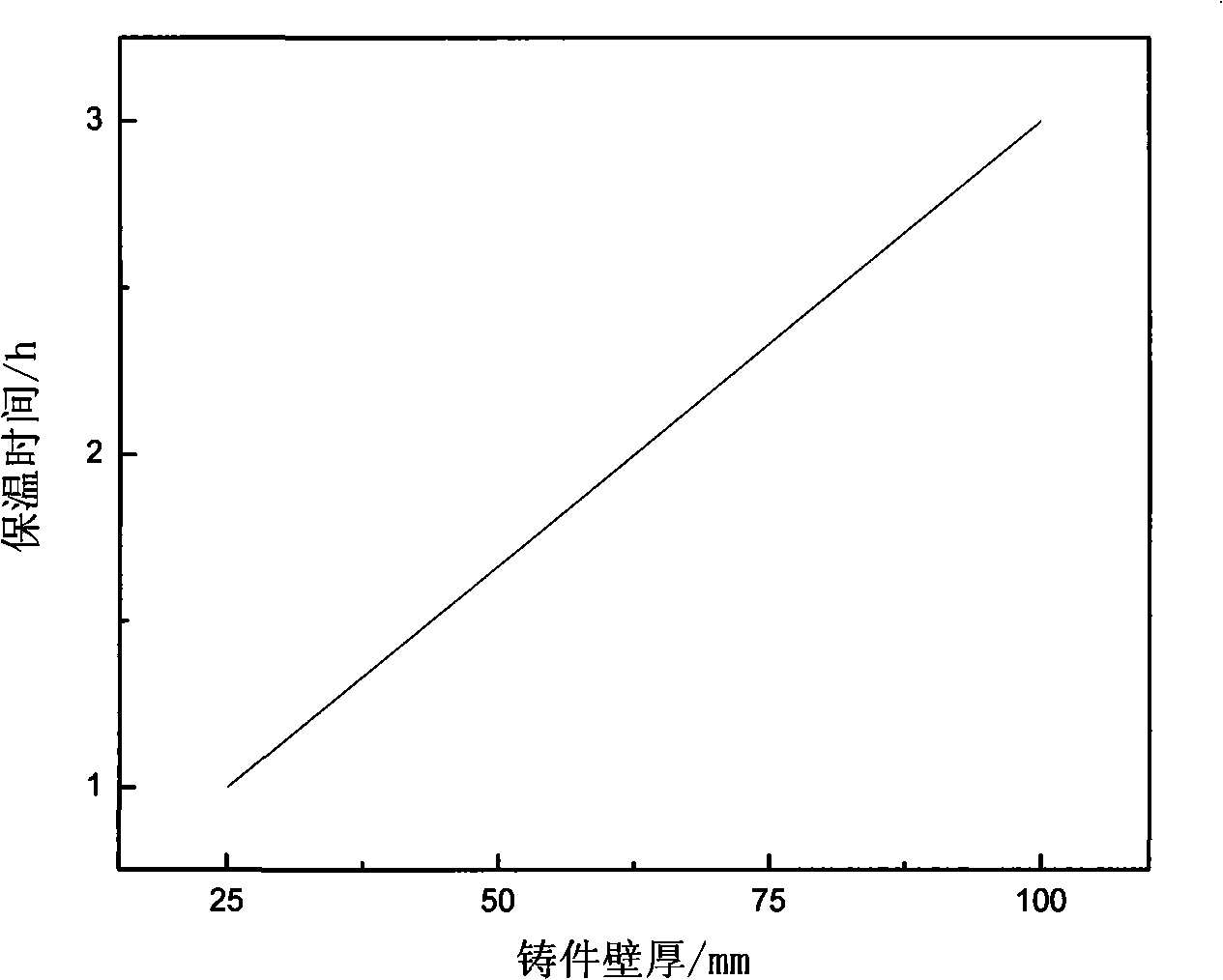

[0043] (4), water toughness treatment

[0044] The castings are treated with water toughening, the temperature is 1100℃, and the quality of the cooling water is 20 times that of the castings.

[0045] Implementation result:

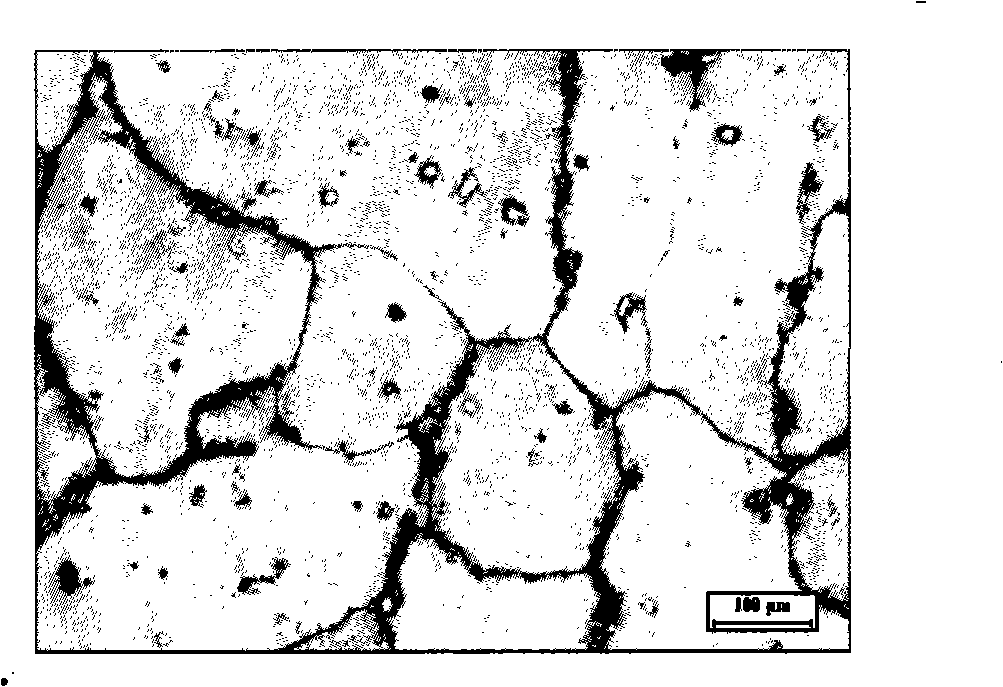

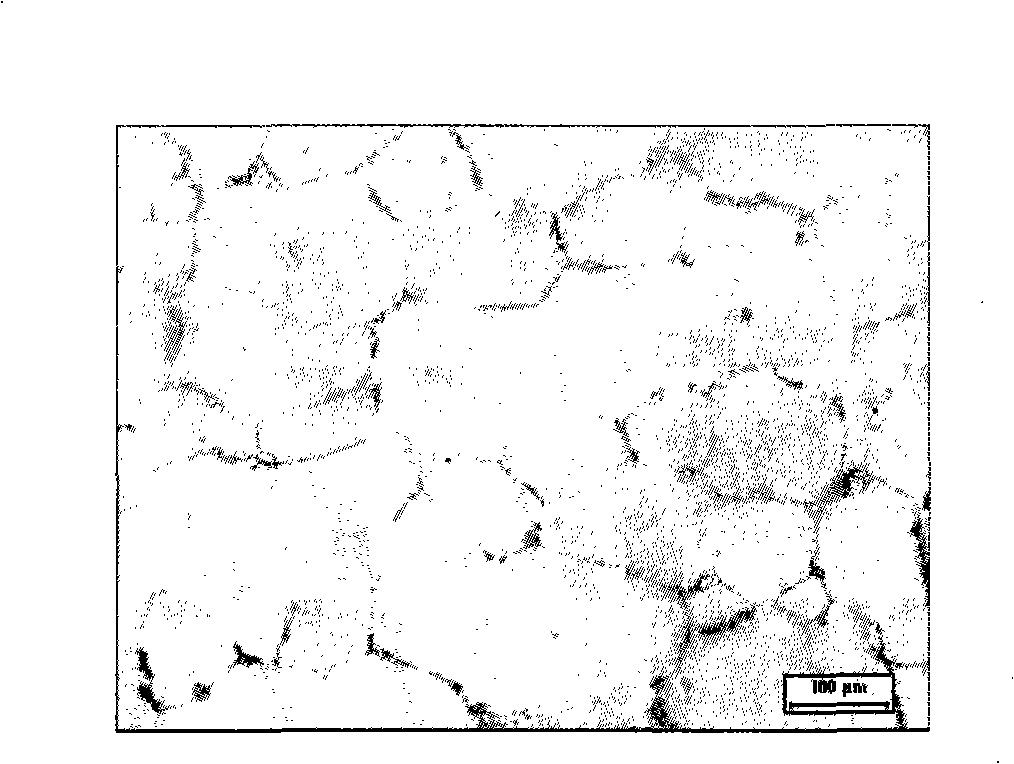

[0046] (1) The microstructure of the high manganese steel after the modification of the yttrium-based heavy rare earth has been...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com