Double Brewster's angle nonlinear optical crystal and cutting method thereof

A technology of nonlinear optics and Brewster angles, applied in the field of double Brewster angle nonlinear optical crystals and their cutting, can solve problems such as reflection loss, and achieve the effect of avoiding surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

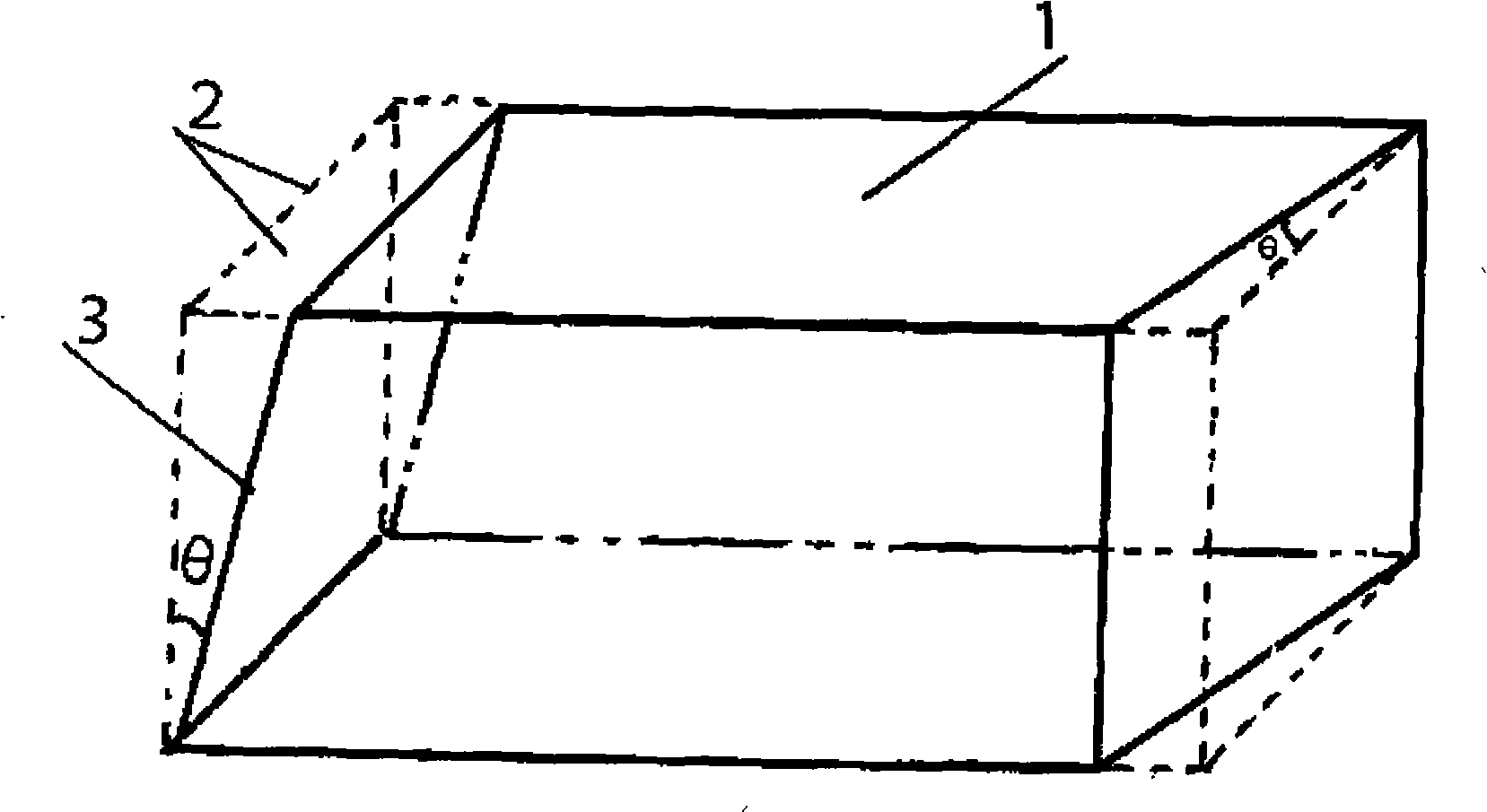

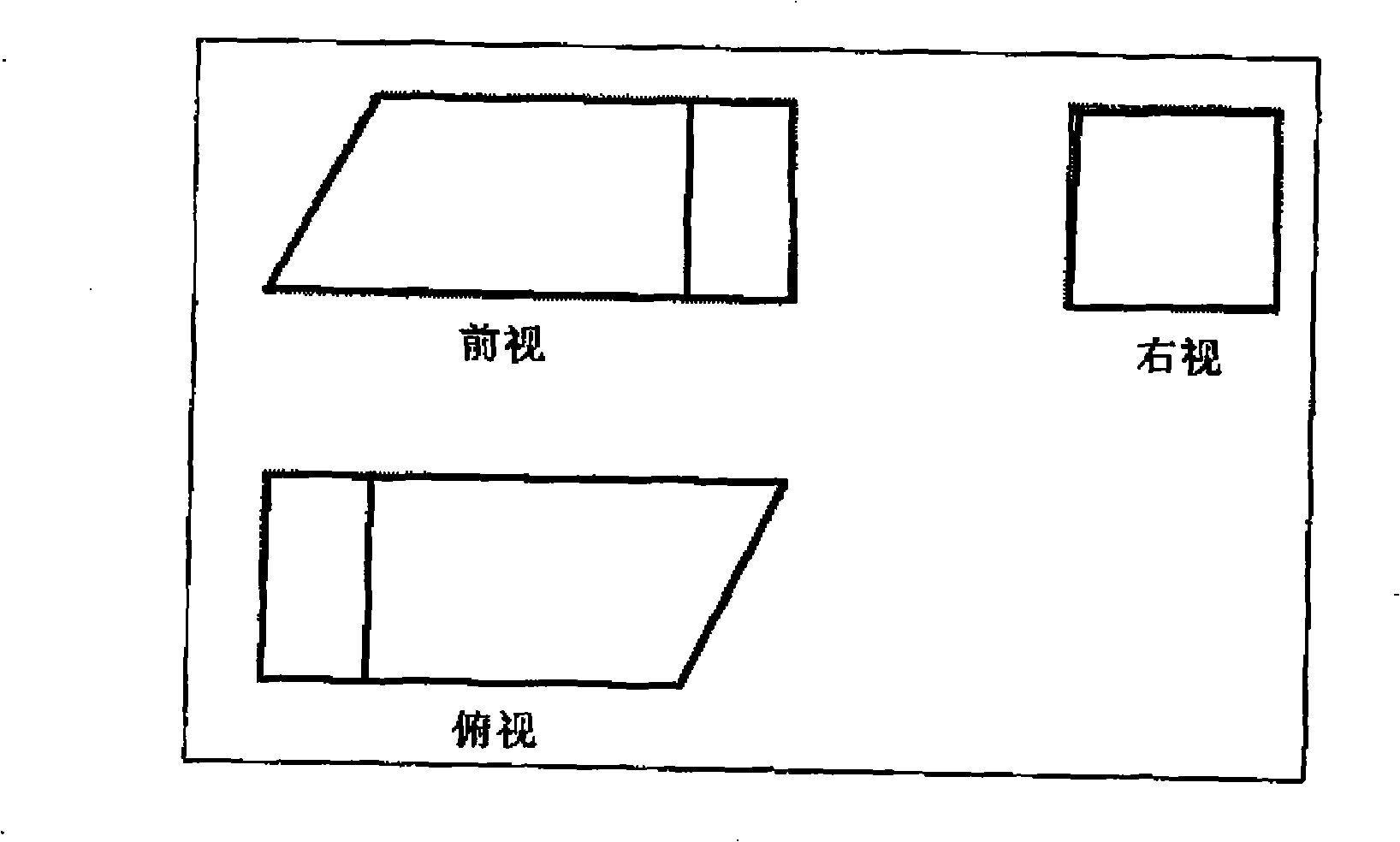

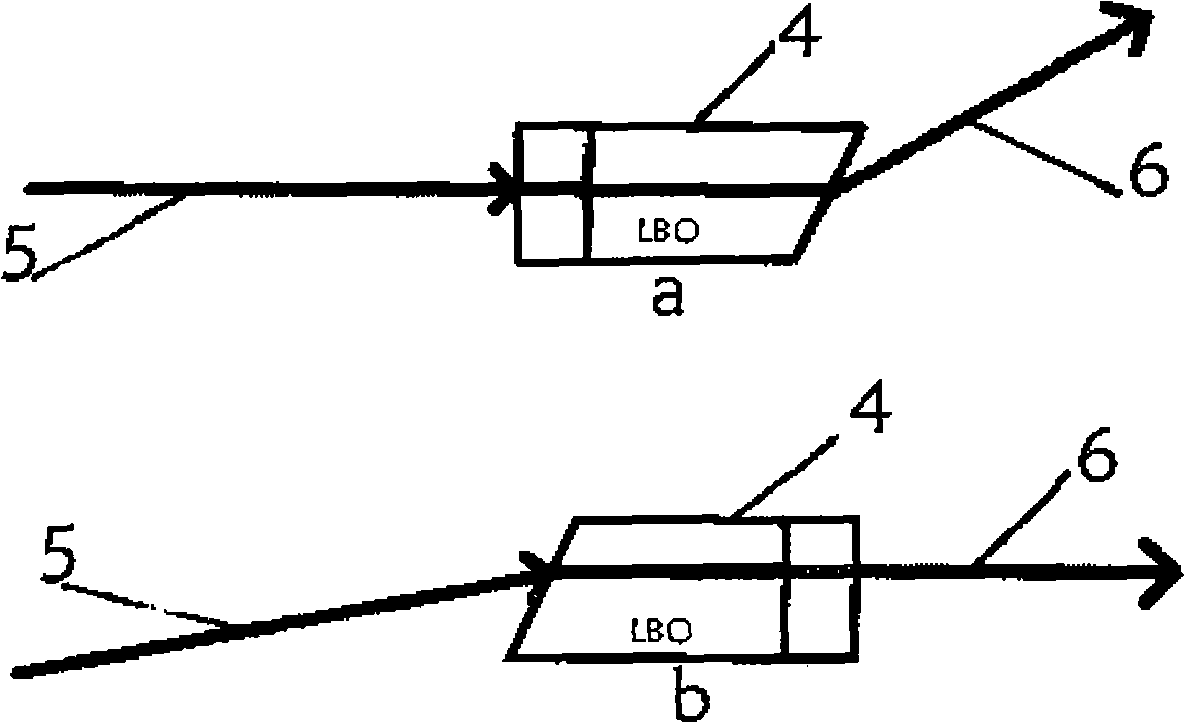

[0027] exist image 3 Among them, the LBO crystal 4 is a type I phase matching and frequency crystal, which adopts figure 1 The light input and output surfaces shown are cut according to Brewster's angle θ, and the incident beam 5 is a mixed beam of 1064nm infrared light and 532nm green light, which is incident at a special angle of Brewster's angle according to the incident light To the light input surface cut according to the Brewster angle, the reflected light and the refracted light are perpendicular to each other, the mixed light beam 5 is incident on the light input surface at the Brewster angle θ, so that the 1064nm infrared light and The polarization direction of 532nm green light is parallel to the front view plane (such as image 3 As shown in b), it is transmitted into the LBO crystal 4 without reflection loss, and a type I phase-matched sum frequency occurs, and the outgoing light 6 of 355nm sum frequency light (ultraviolet light) is generated. The polarization d...

Embodiment 2

[0029] Such as Figure 4 In the schematic diagram of the quadruple frequency doubling scheme shown, the cavity mirror M1 has a high reflectivity, and the output cavity mirror M2 has a reflectivity of 90%, and the two form a resonant cavity 8 . The Nd-YVO4 laser crystal between M1 and M2 is pumped by two laser pumping sources LD that generate pump light with a wavelength of 808nm, and the incident light 5 generated is infrared light with a wavelength of 1064nm. Q-Swithch stands for an optical Q-switched crystal, which is used to generate laser pulses. LBO crystal 4 is a type-I phase-matching frequency-doubling crystal, which generates 532nm green light by frequency doubling 1064nm laser, and CLBO crystal 7 is a type-I phase-matching frequency-doubling crystal, which generates 266nm ultraviolet light 6 by frequency doubling 532nm green light. Both LBO crystal 4 and CLBO crystal 7 are cut according to the double Brewster angle θ.

[0030] The polarization direction of the 1064n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com