Process and equipment for etching and drying silicon solar cell

A technology of silicon solar cells and drying process, applied in the direction of circuits, electrical components, cleaning methods and utensils, etc., can solve the problems of high energy consumption, danger, high consumption of chemical reagents and water sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

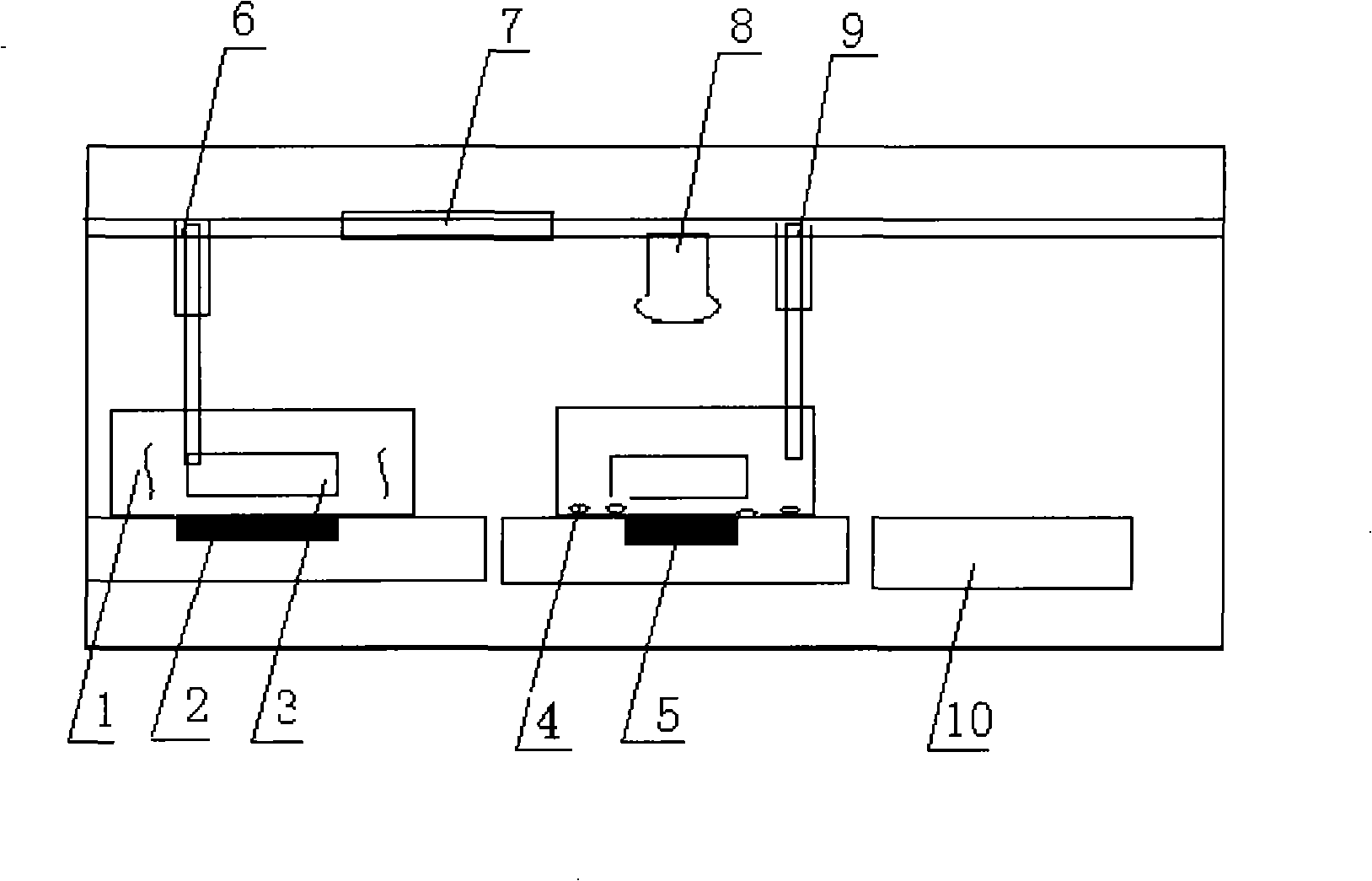

[0017] Cleaning, etching and drying process of silicon solar cells, using megasonic energy to generate O 3 , as an etching solution to clean the silicon wafer, and add HF to remove metal ions and SiO 2 layer, the specific steps are:

[0018] ① Megasonic tank cleaning to remove the damaged layer: use megasonic to generate O in deionized water 3 , O 3 The solubility is above 10ppm, and HF is added in deionized water, the HF concentration is 2-5%, and the cleaning is carried out at room temperature, and the ideal temperature is controlled at 23°C; To the effect of uniform cleaning;

[0019] ② Put the silicon wafer into deionized water for ultrasonic cleaning, in which the megasonic frequency is above 1MHZ, and the power is adjustable from 50 to 600W; it can remove the influence of F ions, achieve a uniform cleaning effect, and make the cleaning more thorough;

[0020] ③ After the above cleaning, dry the silicon wafer when it is lifted out of the liquid surface. A set of N 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com