Wet-rub resistant styrene-acrylic emulsion and preparation thereof

A styrene-acrylic emulsion and moisture-resistant technology, which is applied in the field of polymer emulsions, can solve problems such as failure to meet requirements, and achieve the effects of easy control, simple process, and stable polymerization system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

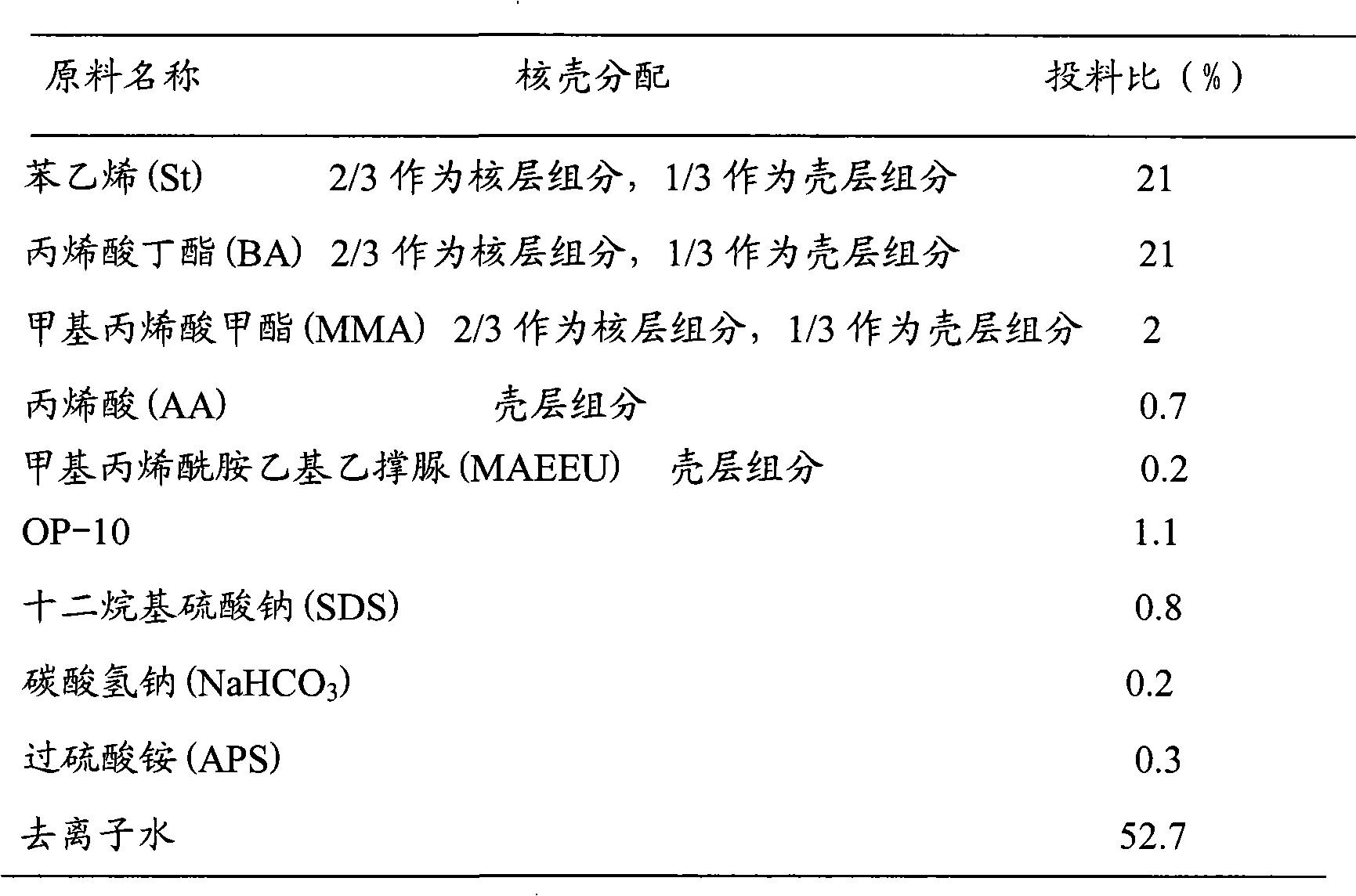

[0015] 1. The raw material formula of styrene-acrylic emulsion is as follows:

[0016]

[0017] Two, the preparation method of styrene-acrylic emulsion is as follows:

[0018] First, dissolve 2 / 3 of the emulsifier SDS and OP-10 in water, then mix with 2 / 3 of styrene (St), butyl acrylate (BA), and methyl methacrylate (MMA), and stir vigorously for 30 minutes. Obtain a uniform and stable pre-emulsion A; then another part of the compound emulsifier and the remaining styrene (St), butyl acrylate (BA), methyl methacrylate (MMA) and acrylic acid (AA) and methacrylamide Ethylene ethylene urea (MAEEU) was mixed, vigorously stirred for 30 minutes to obtain a uniform and stable pre-emulsion B; the initiator was dissolved in deionized water to make solution C; sodium bicarbonate was dissolved in deionized water to make solution D; Add 1 / 3 each of pre-emulsion A and solution C, deionized water and solution D into the reactor, stir and heat to 78°C for 30 minutes, then add the remainin...

Embodiment 2

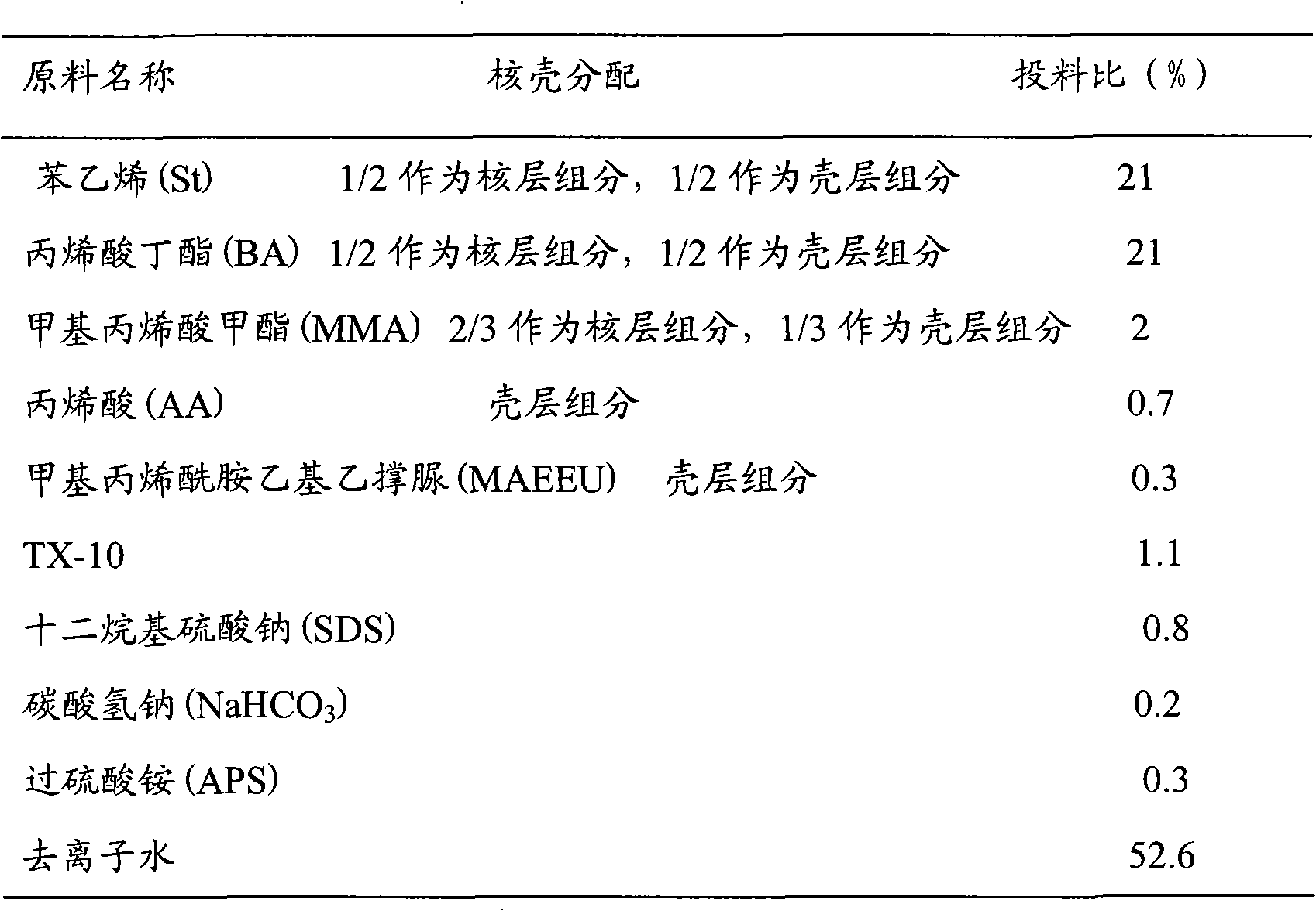

[0020] 1. The raw material formula of styrene-acrylic emulsion is as follows:

[0021]

[0022] Two, the preparation method of styrene-acrylic emulsion is as follows:

[0023] First, dissolve 1 / 2 of the emulsifier SDS and TX-10 in water, and then mix with 1 / 2 and 1 / 3 of methyl methacrylate (MMA) of styrene (St) and butyl acrylate (BA). Stir for 30 minutes to obtain a uniform and stable pre-emulsion A; then another part of the compound emulsifier and the remaining styrene (St), butyl acrylate (BA), methyl methacrylate (MMA) and acrylic acid (AA) and Mix methacrylamide ethyl ethylene urea (MAEEU) and stir vigorously for 30 minutes to obtain a uniform and stable pre-emulsion B; dissolve the initiator in deionized water to make solution C; dissolve sodium bicarbonate in deionized water to make Solution D: Take 1 / 3 each of pre-emulsion A and solution C, deionized water and solution D into the reaction kettle, stir and heat to 78°C for 45 minutes, then add the remaining pre-emul...

Embodiment 3

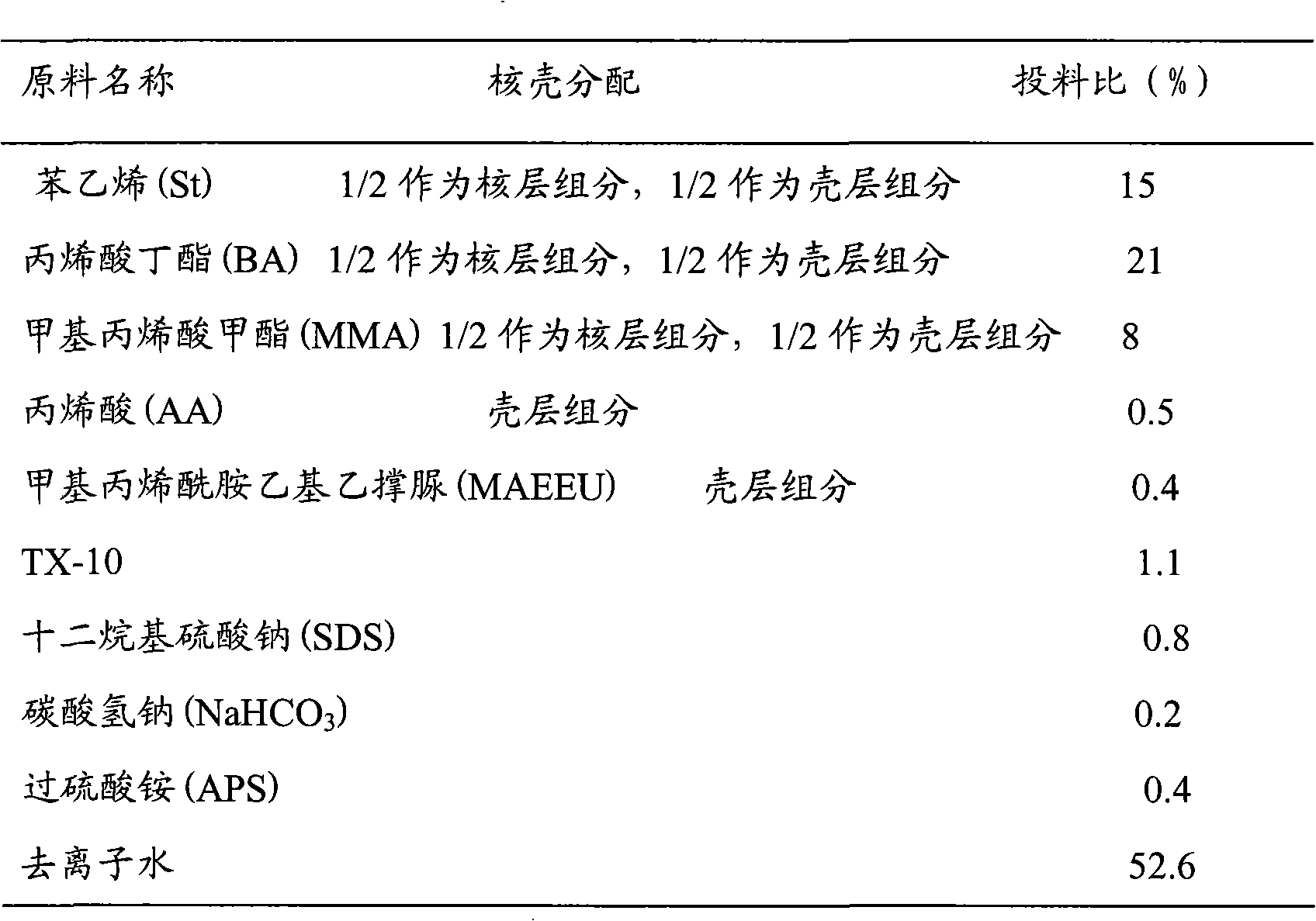

[0025] 1. The raw material formula of styrene-acrylic emulsion is as follows:

[0026]

[0027] Two, the preparation method of styrene-acrylic emulsion is as follows:

[0028] First, dissolve 1 / 2 of the emulsifier SDS and TX-10 in water, then mix with 1 / 2 of styrene (St), butyl acrylate (BA), and methyl methacrylate (MMA), and stir vigorously for 45 minutes. Obtain a uniform and stable pre-emulsion A; then another part of the compound emulsifier and the remaining styrene (St), butyl acrylate (BA), methyl methacrylate (MMA) and acrylic acid (AA) and methacrylamide Ethylene ethylene urea (MAEEU) was mixed, vigorously stirred for 45 minutes to obtain a uniform and stable pre-emulsion B; the initiator was dissolved in deionized water to make solution C; sodium bicarbonate was dissolved in deionized water to make solution D; Add 1 / 3 each of pre-emulsion A and solution C, deionized water and solution D into the reactor, stir and heat to 80°C for 45 minutes, then add the remainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com