Instrument and method for real time monitoring optical fibre distributed multi-point mash gas

A fiber optic distributed, real-time monitor technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of inflexible sensor access, short service life, frequent adjustment, etc., to overcome the susceptibility to interference, reduce costs, improve The effect of detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

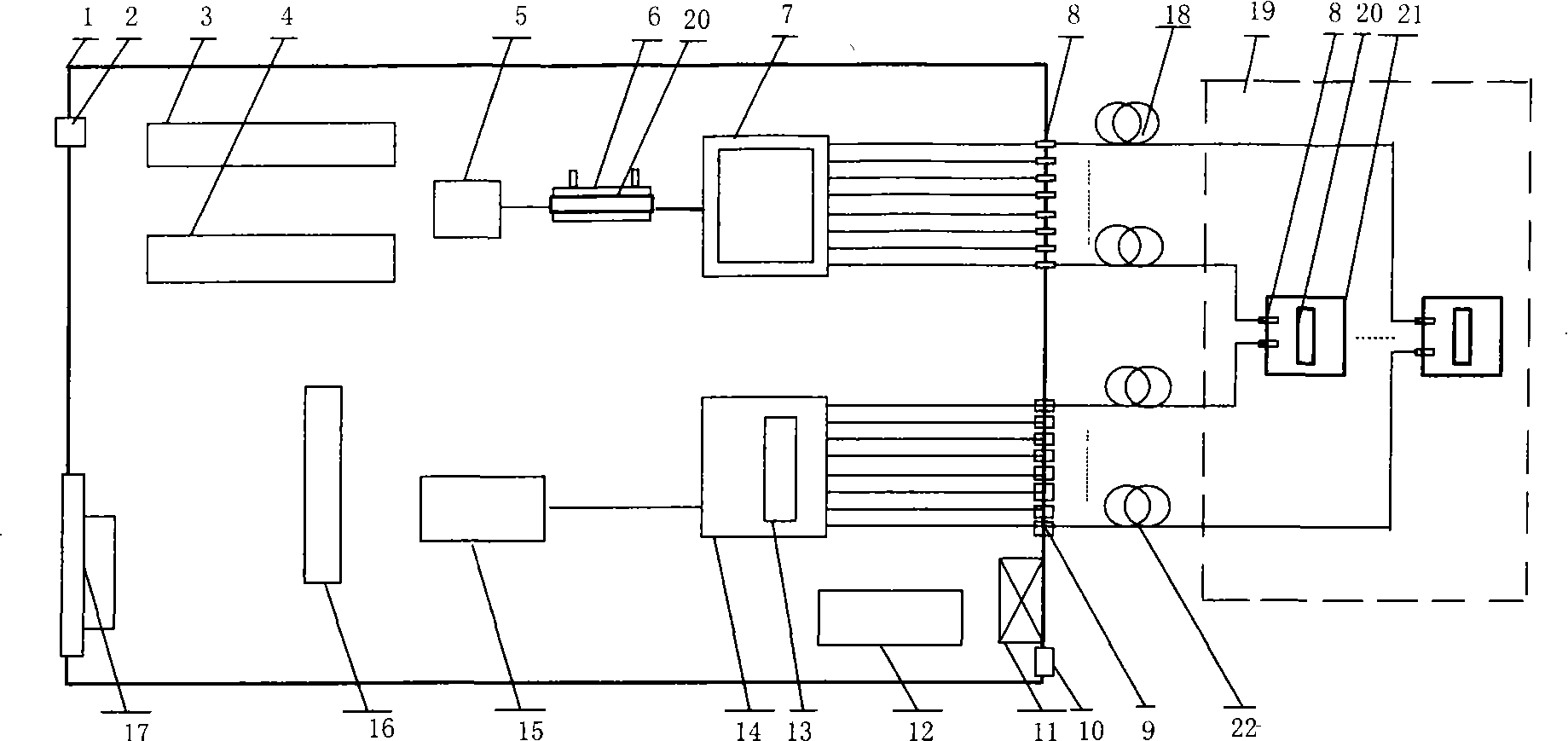

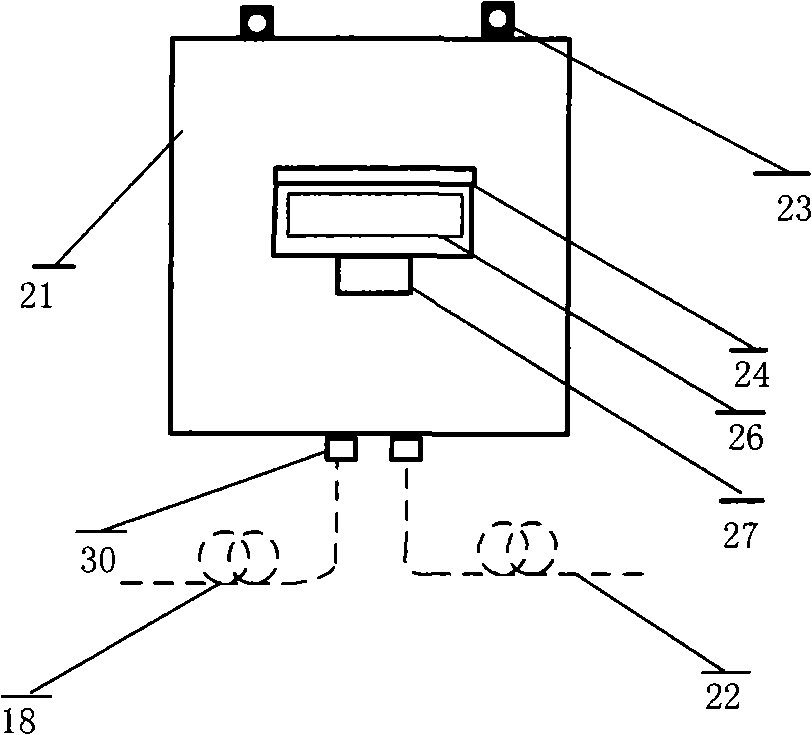

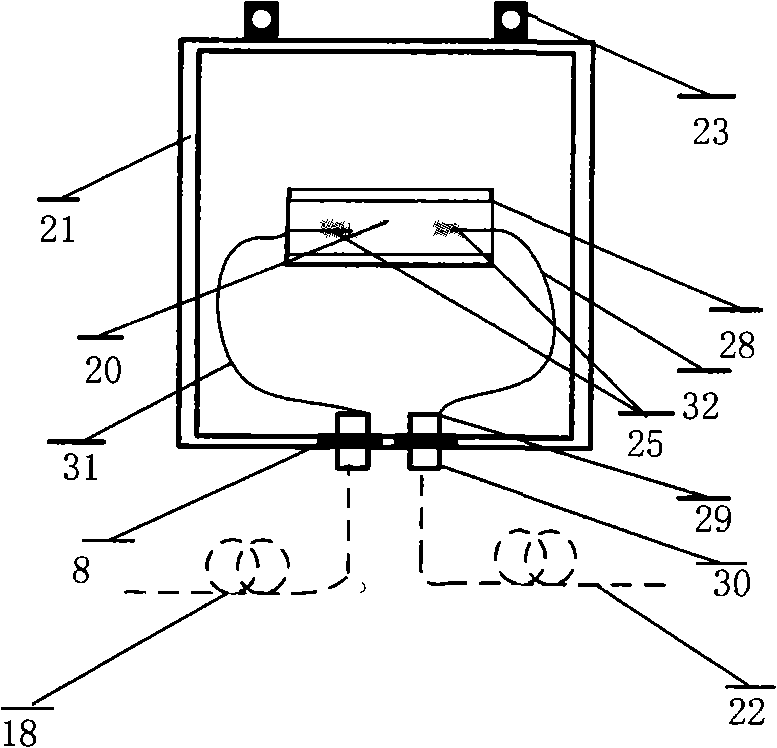

[0014] see figure 1 , figure 2 , image 3 , Figure 4 .

[0015] Labels in the figure: 1. Main box, 2. Main power switch, 3. 1653nm semiconductor laser temperature and current control module, 4. Signal generation circuit, 5. 1653nm near-infrared DFB semiconductor laser, 6. Gas calibration pool, 7. 1× N (N 1~64 optional, determined by the laser power and the number of points required to be measured) optical fiber splitter, 8, output flange, 9, infrared photodetector, 10, main power socket, 11, fan, 12, DC stabilized power supply, 13. N-way analog signal switch, 14. N-way analog signal switch drive circuit, 15. Lock-in amplifier board, 16. Data acquisition, processing and control module, 17. Liquid crystal display. The components involved in the above are all installed on the chassis. 18. Input single-mode optical fiber, 19. Downhole detection optical path, 20. Micro optical absorption cell, 21. External protection box, 22. Output single-mode optical fiber. The following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com