Tar cracking device of biomass gasifier

A technology of tar cracking and gasification furnace, which is applied in the direction of tar processing through heat treatment, etc. It can solve the problems of secondary pollution cost, affecting the calorific value of gas, secondary pollution, etc., and achieve sufficient tar cracking, improved quality, and convenient operation Effect

Inactive Publication Date: 2008-10-15

ZHANGJIAJIE SANMU ENERGY DEV

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existence of tar is unfavorable to the utilization of biomass gas, which not only reduces the benefit of biomass gasification, but also causes energy waste

Especially the tar in the gas produced by the household biomass gasifier is transported from the air guide pipe to the purifier with the gas, and then the purifier is transported to the gas stove through the pipeline. During this period, the tar condenses into a liquid when it gradually cools from heat, And combined with elements such as water and carbon, it not only affects the calorific value of the gas, but more importantly, it is easy to cause the gasifier to block the gas pipeline

This is the main reason why the existing biomass gasification stoves are difficult to be widely promoted

The existing tar treatment methods in biomass mixed gas are mainly physical separation, including water washing method, inhalation method, centrifugal separation method, etc., not only the separation effect is poor, but also there is secondary pollution, practice has proved that it is not suitable for promotion

Use centrifugal principle to remove tar, but this method still has energy waste and secondary pollution

In general, the existing tar treatment methods in biomass mixed gas all have defects such as poor tar separation effect, complicated technology, secondary pollution and high cost, and are especially not suitable for the application of household biomass gas stoves

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

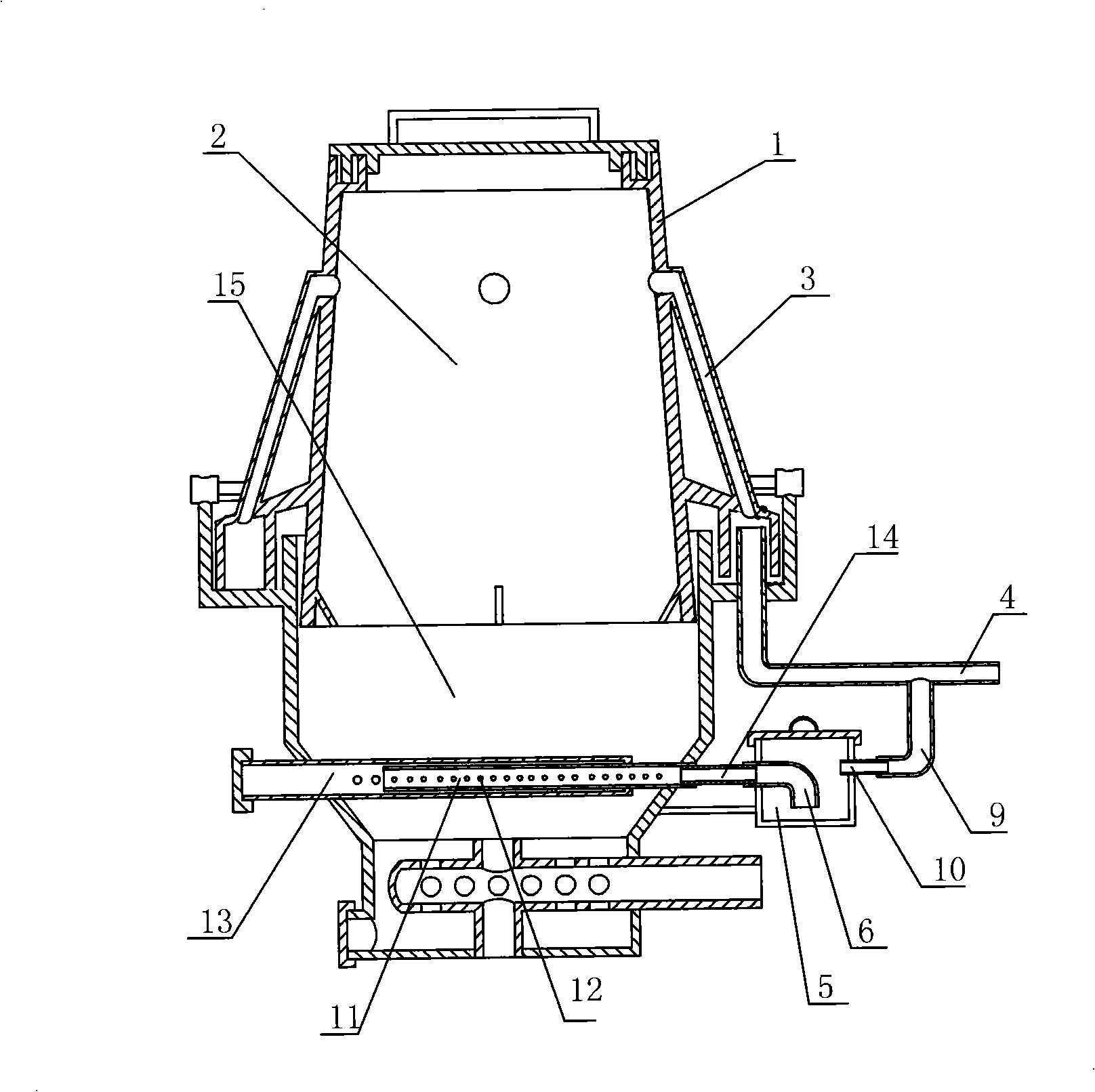

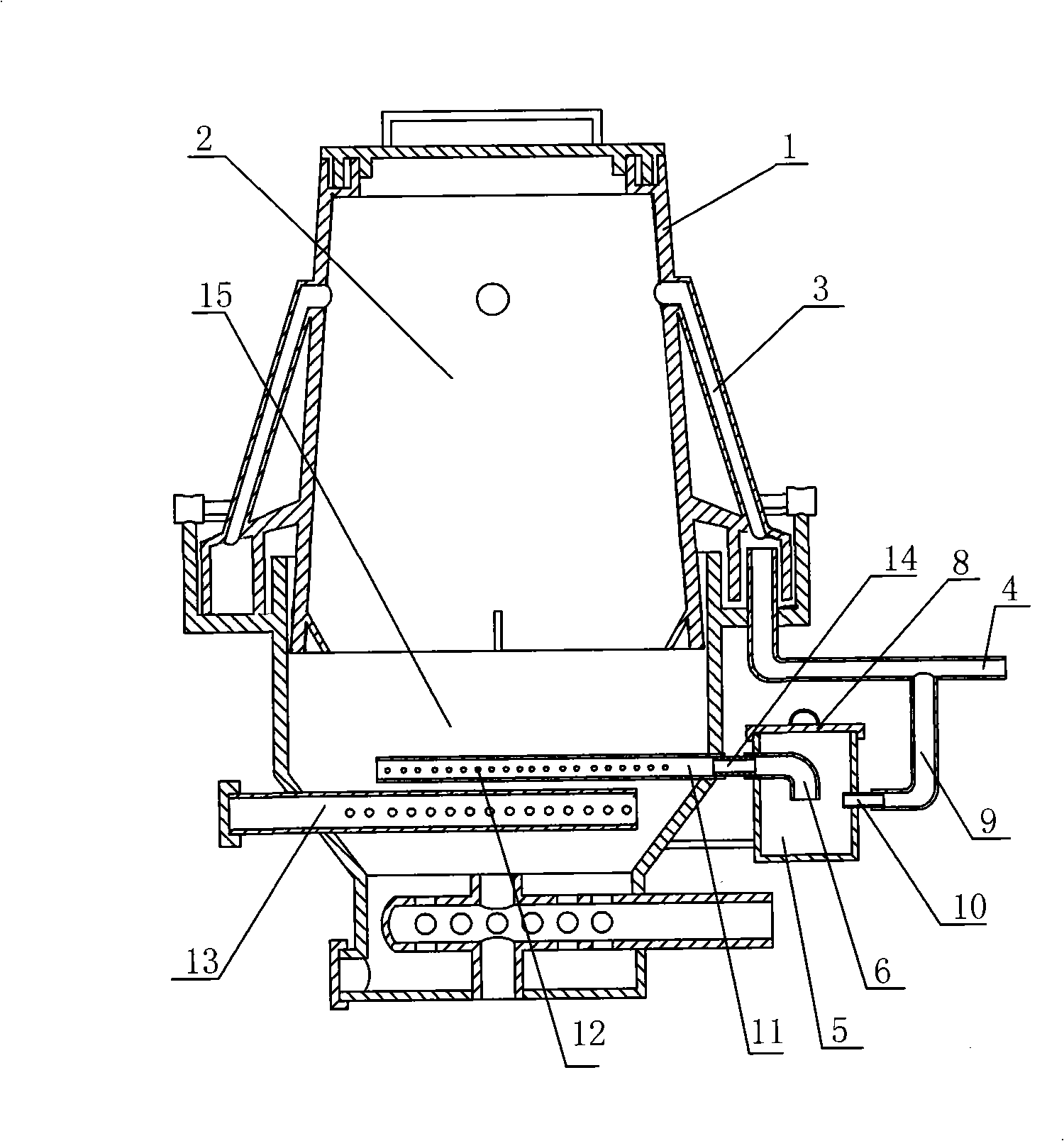

The invention relates to a tar cracking device for biomass gasifiers. The lower part outside a furnace hearth (2) is provided with a reflow device (5); a V-shaped pipe (6) is arranged in the reflow device (5); one end of the V-shaped pipe (6) stretches into the hollow lower part of the reflow device (5); the other end of the V-shaped pipe (6) is connected with a cracking reaction pipe (11) and stretches into a furnace hearth high temperature area (15); the reflow device (5) is communicated with a gas transmission pipe (4) through a reflow pipe (9); a reaction hole (12) is arranged on the cracking reaction pipe; the reflow device (5) is arranged lower than the gas transmission pipe (4). The tar cracking device has tar and water reflow to enter the furnace hearth, utilizes the high temperature produced in the working process of a gasifier to transform tar and water into combustible gas, realizes tar cracking without additional heat source, cracks tar fully, produces no matter such as black charcoal, cannot cause secondary pollution, and can improve the quality of produced gas. In addition, the tar cracking device is simple in structure and very convenient to operate.

Description

A kind of tar cracking device of biomass gasification furnace technical field The invention relates to a tar treatment device, in particular to a tar treatment device for biomass gasification furnace gas. Background technique Biomass gas is a kind of combustible gas produced by using plant fuel to pass through the gas furnace, under the condition of airtight and hypoxic, using dry pyrolysis and thermochemical oxidation method, also known as wood tar, which is black or dark brown, viscous Viscous, is a by-product of biomass gas. Tar is a mixture of gas and gas at high temperature, and condenses into a liquid state within 200°C. The existence of tar is unfavorable to the utilization of biomass gas, which not only reduces the benefit of biomass gasification, but also causes energy waste. Especially the tar in the gas produced by the household biomass gasifier is transported from the air guide pipe to the purifier with the gas, and then the purifier is transported to the ga...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10B53/02C10C1/19

Inventor 周松林周海军

Owner ZHANGJIAJIE SANMU ENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com