Ion beam emission source for outputting single ionic energy

An ion energy and emission source technology, applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the problems of difficulty in achieving ion beam repeatability, large influence on film quality, etc., and reduce diversity factors. Effects of interference, wide energy adjustment range, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

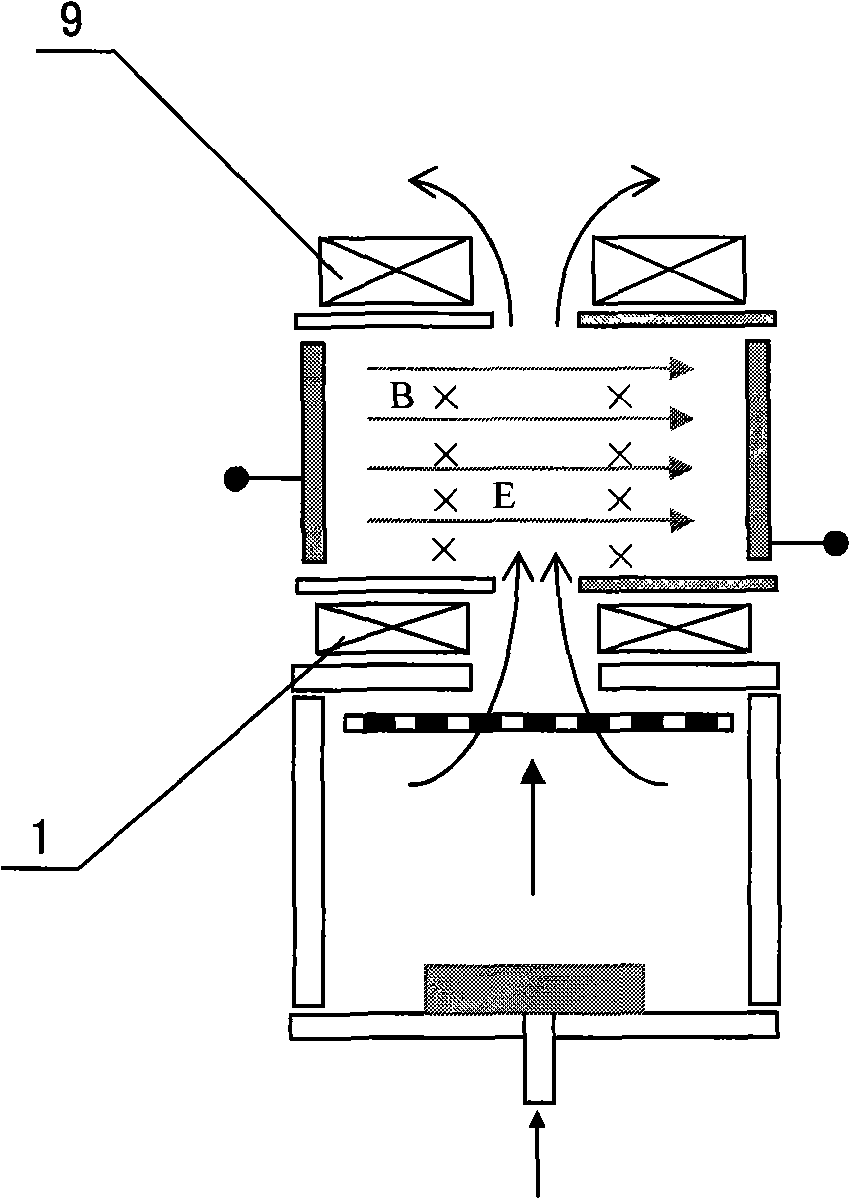

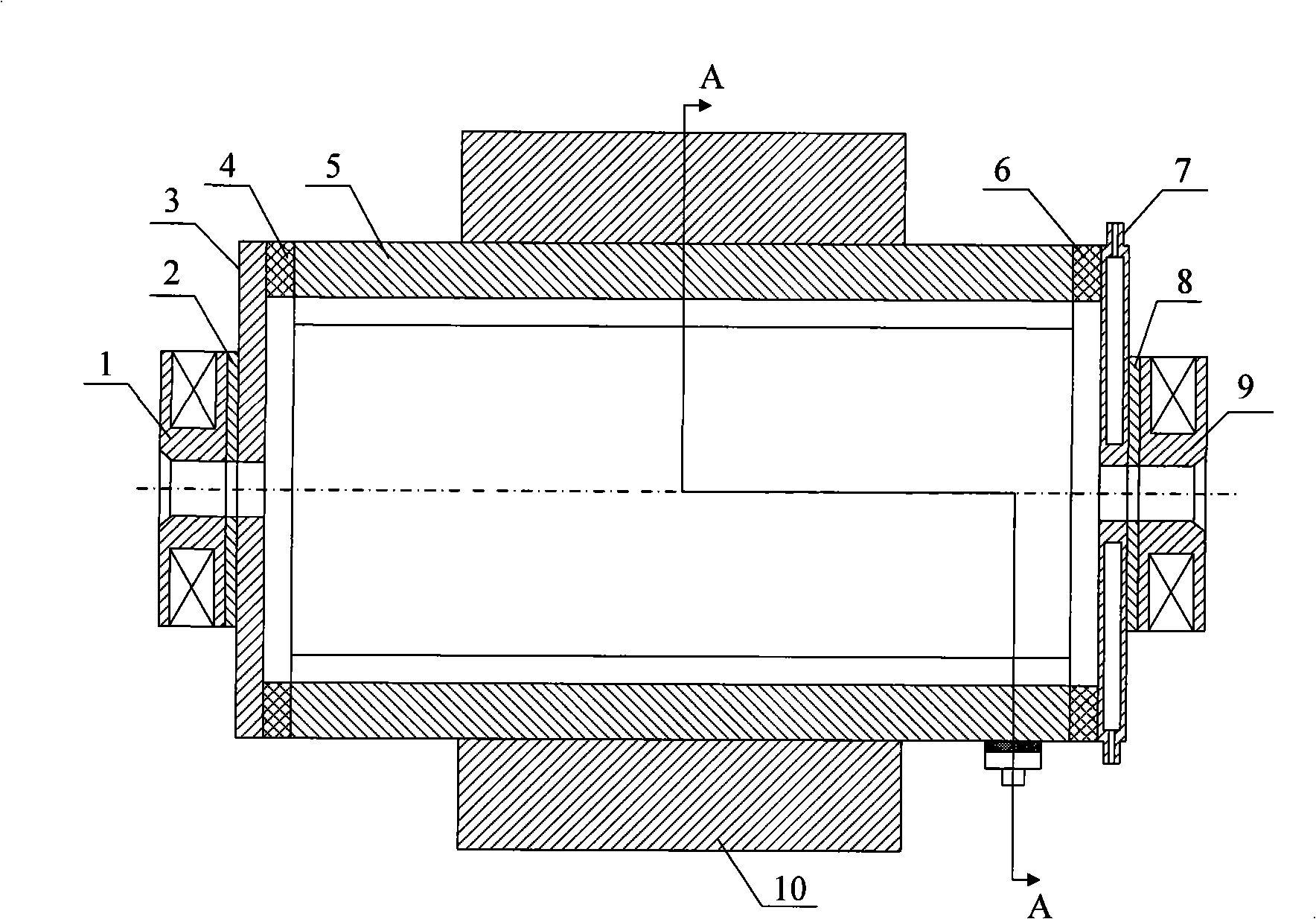

Method used

Image

Examples

Embodiment 1

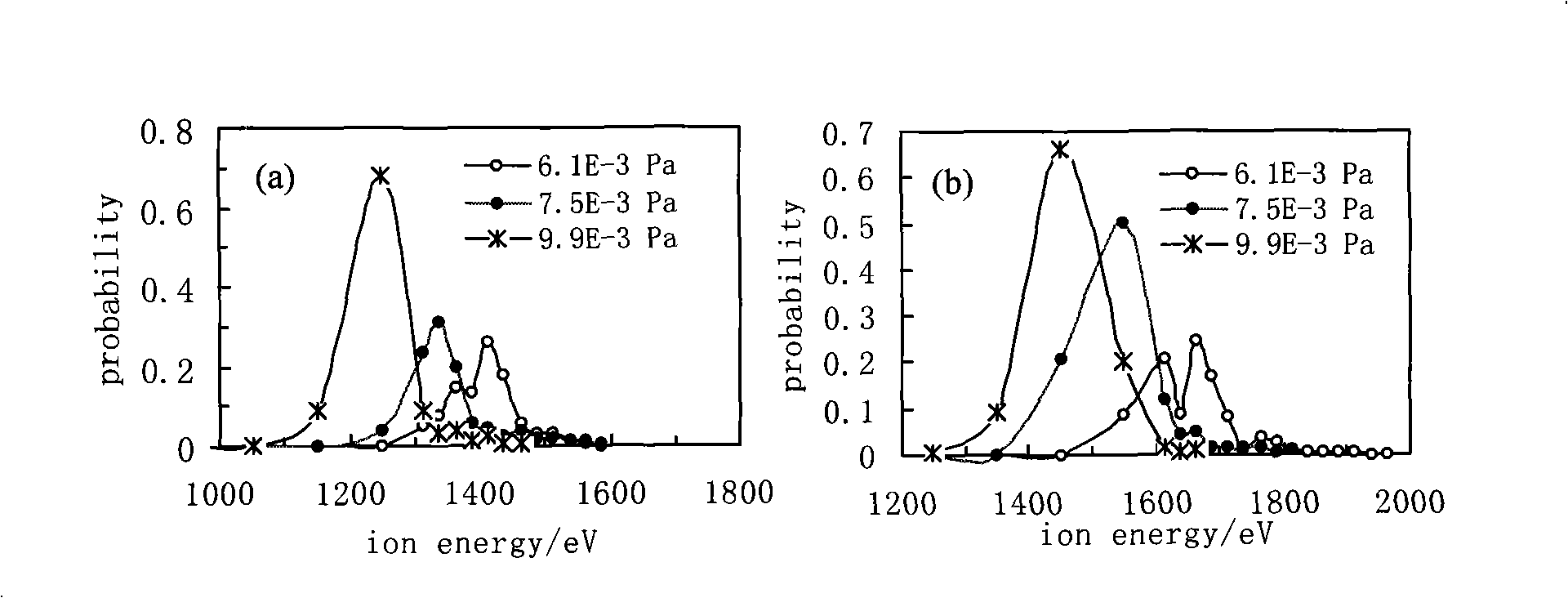

[0050] In the preparation of optical thin films, it is usually necessary to use ion beam assisted deposition to improve the film quality of the thin film. The study found that different thin film materials require different ion beam energies to assist. When preparing the ZnS thin film, the ion beam energy required for assisting is 800eV. If the energy is too low, the best assisting effect cannot be obtained, and if the energy is too high, the formed thin film will be sputtered off. Therefore, to adopt the novel ion beam emission source of the present invention, first set the output energy of the ion source to 800eV. During normal operation, the system will automatically adjust the discharge parameters of the ion source to obtain the required output energy value, and adjust to obtain the strongest The ion beam density output. At this time, the energy of the output ions is 800eV.

Embodiment 2

[0052] In the preparation of optical thin films, it is usually necessary to use ion beam assisted deposition to reduce the film forming temperature. Especially when preparing multi-layer thin films, multiple materials are deposited alternately, each material requires different ion beam auxiliary energy, and requires a single energy output. Such as ZnS / MgF 2 When preparing dielectric high-reflection films, ZnS films require an auxiliary ion beam energy of 800eV, while MgF 2 The auxiliary ion beam energy required by the thin film is 1100eV, and both require a single energy output. Therefore, using the novel ion beam emission source of the present invention, the output energies of the ion sources are respectively set to 800eV and 1100eV, and communicate with the host computer. The entire ion source system will automatically adjust the discharge parameters of the ion source according to the actual plated film to obtain the required energy value, and adjust to obtain the stronges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com