An electronic emitter on silicon-based surface and preparation method thereof

A surface electron and emission device technology, applied in the manufacture of semiconductor/solid-state devices, electrical components, electrode systems, etc., can solve the problems of complex manufacturing process, limited development of field emission displays, unsatisfactory emission stability and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

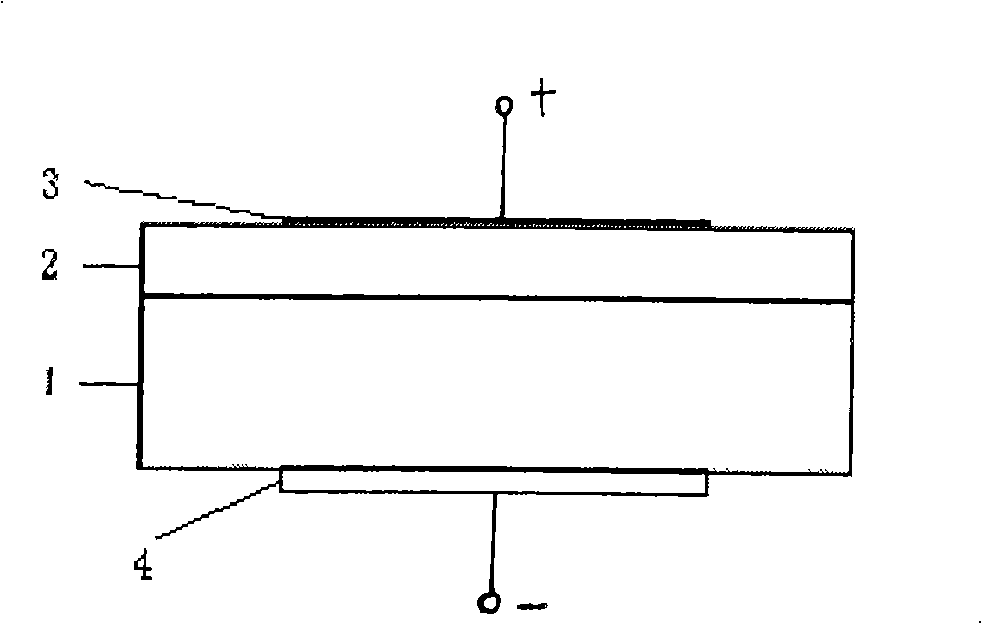

[0020] Take the following process steps:

[0021] 1) Clean n-type , resistivity 0.005 ohm cm, size 15×15mm 2 , a silicon wafer with a thickness of 675 microns;

[0022] 2) Heat the silicon wafer at 900°C for 2 hours in an oxygen atmosphere to obtain SiO with a thickness of 30nm 2 film;

[0023] 3) On SiO 2 A 20nm thick Au film was sputtered on the thin film as a gate, and a 100nm thick Au film was sputtered on the back of the silicon substrate as an ohmic contact electrode.

Embodiment 2

[0025] Take the following process steps:

[0026] 1) Clean n-type , resistivity 0.5 ohm cm, size 15×15mm 2 , a silicon wafer with a thickness of 675 microns;

[0027] 2) With tetraethyl orthosilicate (TEOS) as the gas source, SiO with a thickness of 100 nm was deposited on the silicon wafer by chemical vapor deposition. 2 thin film, the deposition temperature is 500°C, and the working pressure is 100Torr;

[0028] 3) On SiO 2 A 20nm thick Al film was sputtered on the thin film as a gate, and a 100nm thick Au film was sputtered on the back of the silicon substrate as an ohmic contact electrode.

Embodiment 3

[0030] Take the following process steps:

[0031] 1) Clean n-type , the resistivity is 50 ohm cm, the size is 15×15mm 2 , a silicon wafer with a thickness of 675 microns;

[0032] 2) Using sapphire particles as the evaporation source, deposit Al with a thickness of 100nm on the silicon wafer by electron beam evaporation method 2 o 3 film;

[0033] 3) in Al 2 o 3 A 30nm thick Au film was sputtered on the thin film as a gate, and a 100nm thick Au film was sputtered on the back of the silicon substrate as an ohmic contact electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com