Preparation technique of pure complete banana power

A preparation process and technology of banana powder, applied in the field of preparation of pure whole banana powder, can solve the problems of low production cost, high production cost, small one-time investment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

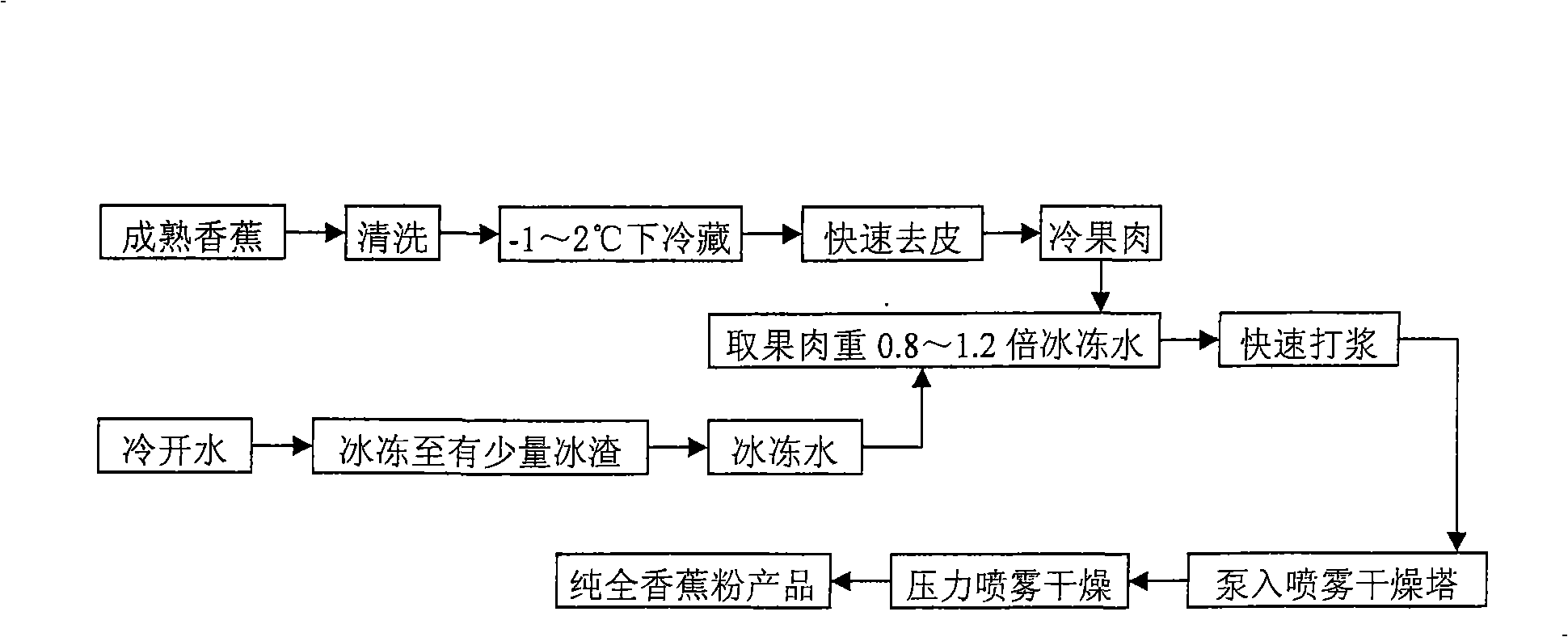

Method used

Image

Examples

Embodiment 1

[0021] Take 164 parts of 7.5 ripe bananas, wash them, refrigerate them at -1°C for 45 minutes, take them out, quickly peel them, put the pulp into 80 parts of frozen water, beat them together with a small amount of ice slag, pump the spray pressure to 7.5 MPa, and the air temperature Dry in a pressure spray drying tower with a temperature of 175°C and an outlet air temperature of 90°C, and collect the cyclone separator and tower bottom products.

Embodiment 2

[0023] Take 164 parts of 8 ripe bananas, wash them, refrigerate them at 0°C for 60 minutes, take them out, quickly peel them, put the pulp into 100 parts of frozen water, and beat them together with a small amount of ice slag. 180°C and a pressure spray drying tower with an outlet temperature of 93°C for drying, and the cyclone separator and tower bottom products are collected.

Embodiment 3

[0025] Take 164 parts of 8 ripe bananas, wash them, refrigerate at 0°C for 60 minutes, take them out, quickly peel them, put the pulp into 120 parts of frozen water, and beat them together with a small amount of ice slag. 185°C and a pressure spray drying tower with an outlet temperature of 95°C for drying, and the cyclone separator and tower bottom products are collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com