Process for producing hydrogen gas and carbon disulphide from hydrogen sulfide

A carbon disulfide, hydrogen production technology, applied in the direction of hydrogen production, etc., to achieve the effects of improved conversion rate, low temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

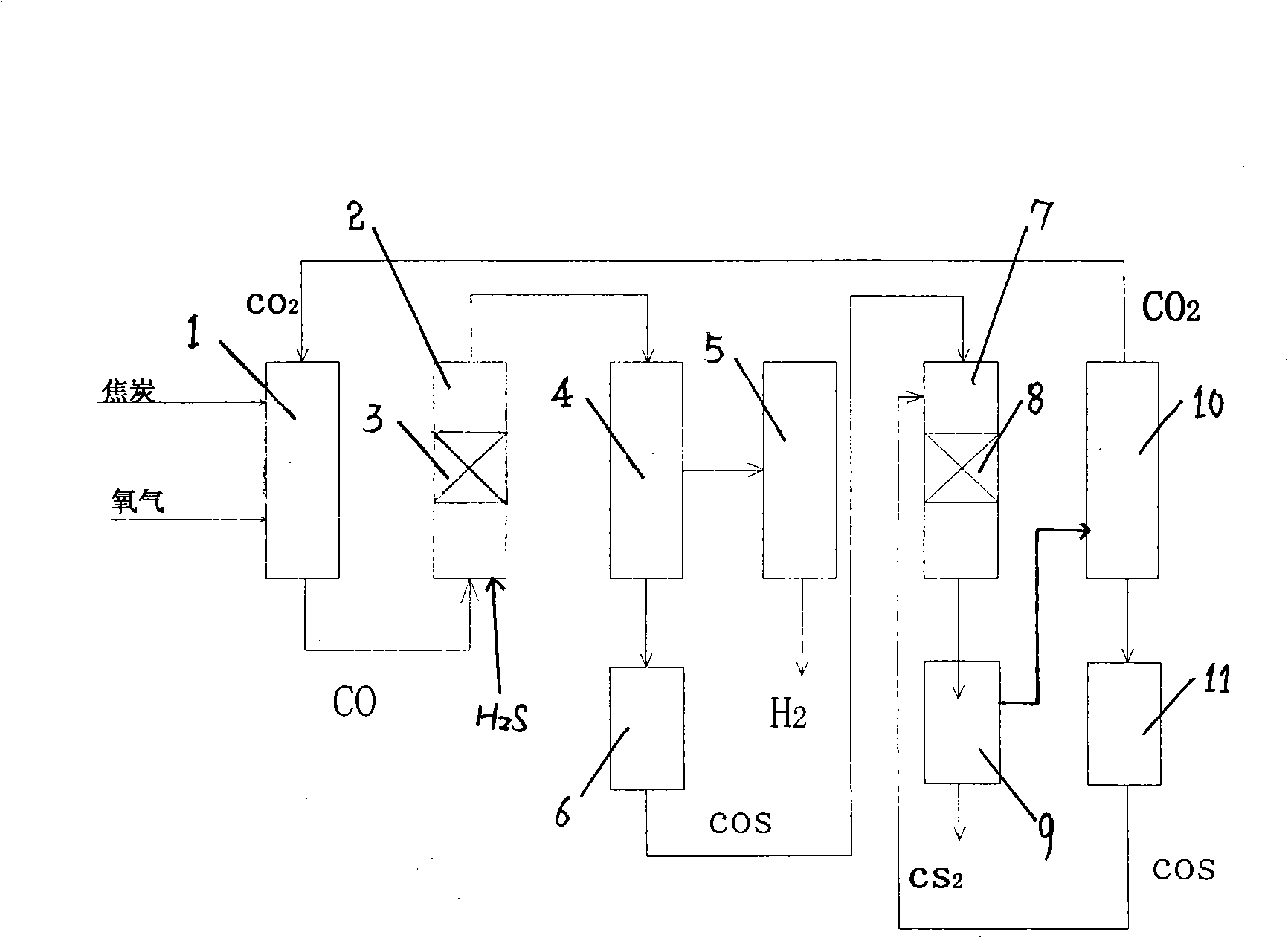

[0023] A method for producing hydrogen and carbon disulfide from hydrogen sulfide, first in the carbon monoxide generator 1, coke is used as raw material, oxygen and carbon dioxide as gasification agent to prepare raw material gas carbon monoxide, and then includes the following steps:

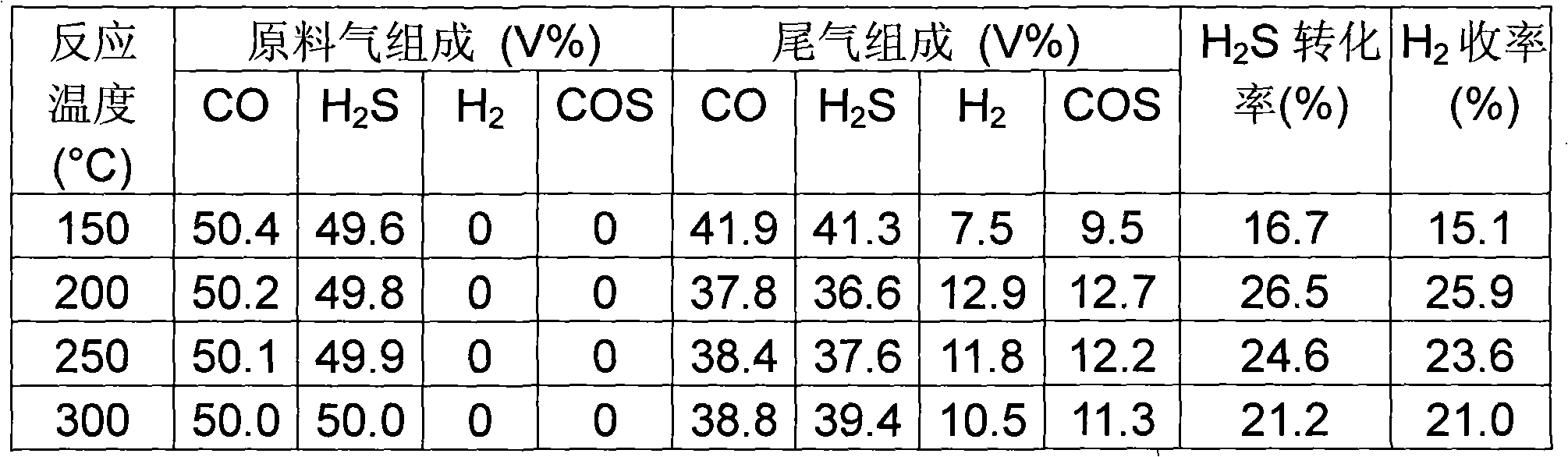

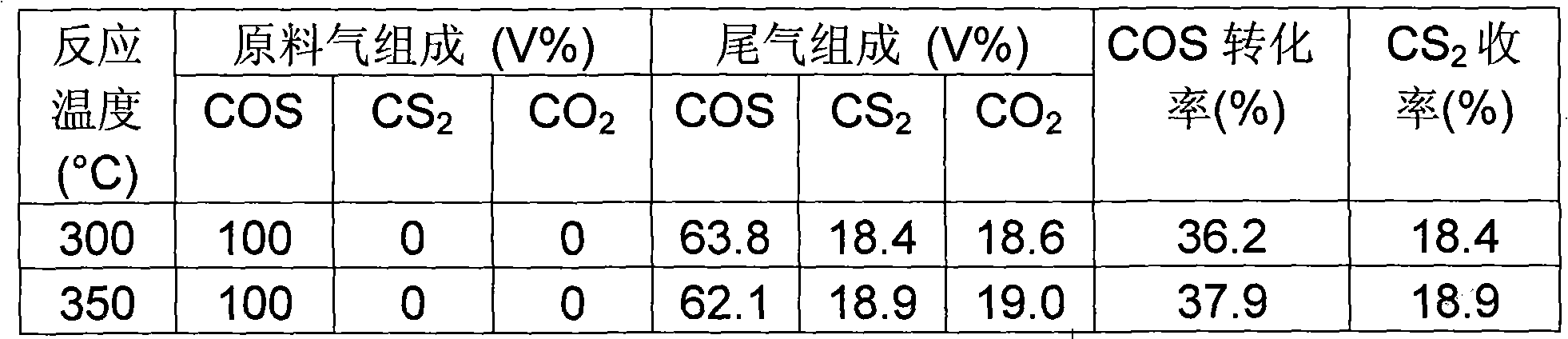

[0024] a. Carbon monoxide and hydrogen sulfide are introduced into the hydrogen sulfide conversion tower 2 equipped with a low-temperature conversion catalyst 3 for reaction to generate a mixed product containing carbon monoxide, hydrogen sulfide, hydrogen and carbonyl sulfide. In this step, the feed gas CO / H 2 The volume ratio of S is 1.0-4.0, the catalytic reaction is carried out at normal pressure and 150-350°C, the reaction space velocity is 500-2000ml / g-cat·h, and the low-temperature conversion catalyst 3 is obtained from VIB group metal Cr , Mo, W, and Group VIII metals Fe, Co, and Ni are randomly selected and mixed in any proportion, and the carrier is Al 2 o 3 , SiO 2 、TiO 2 , ZrO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com