Method for preparing D-phenylalanine

A phenylalanine and process technology, applied in the field of synthesis of unnatural amino acids, can solve problems such as low enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

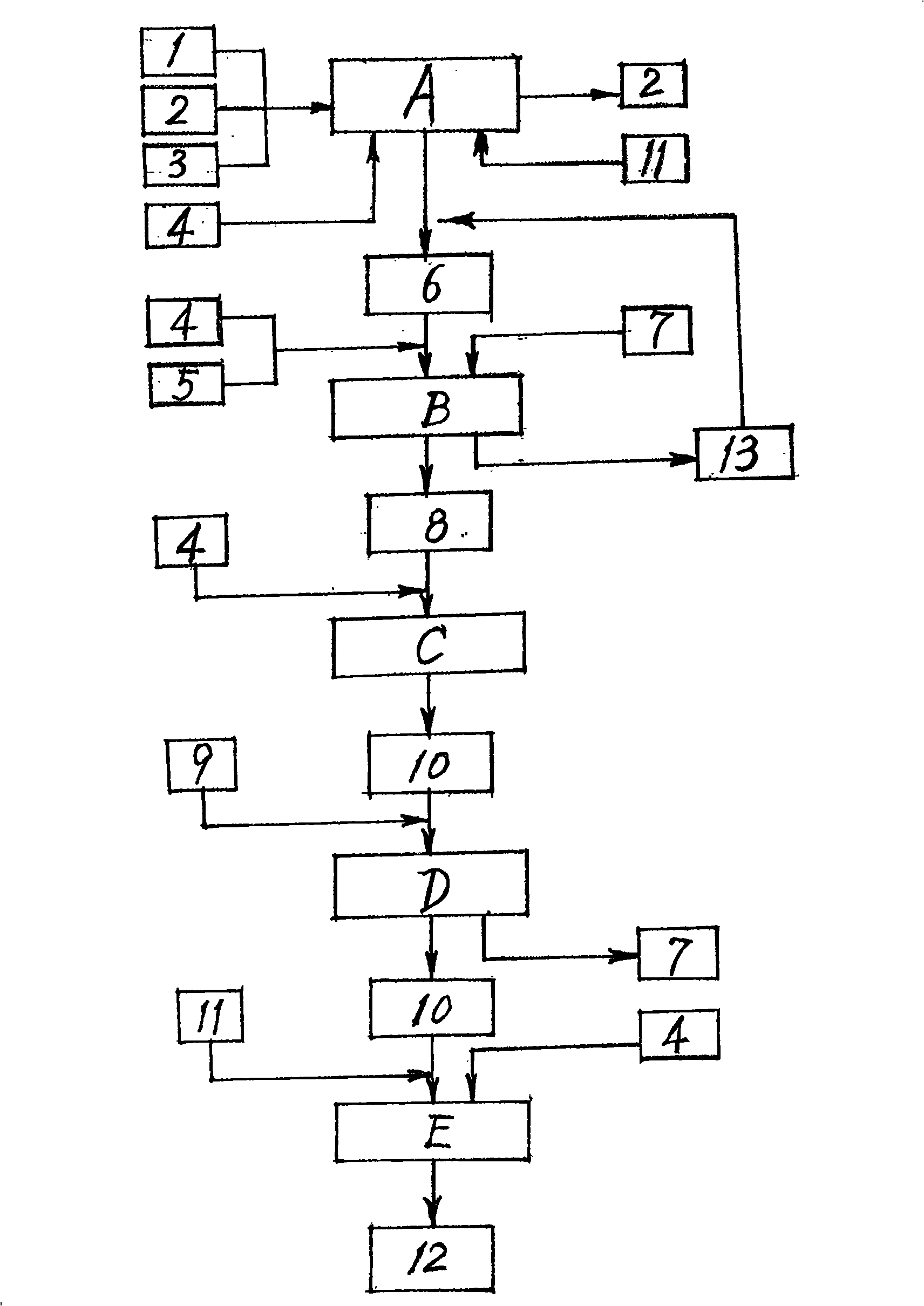

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

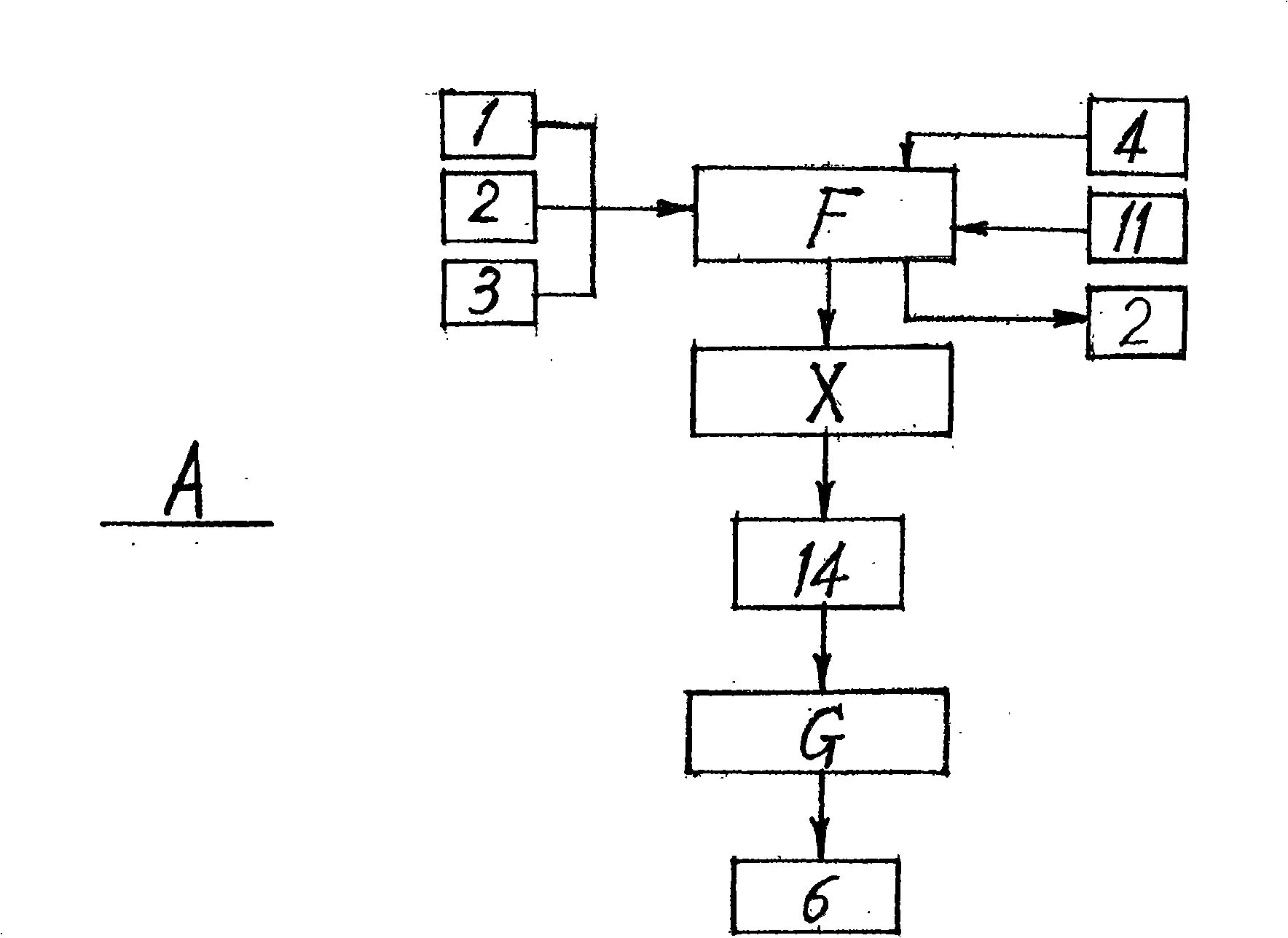

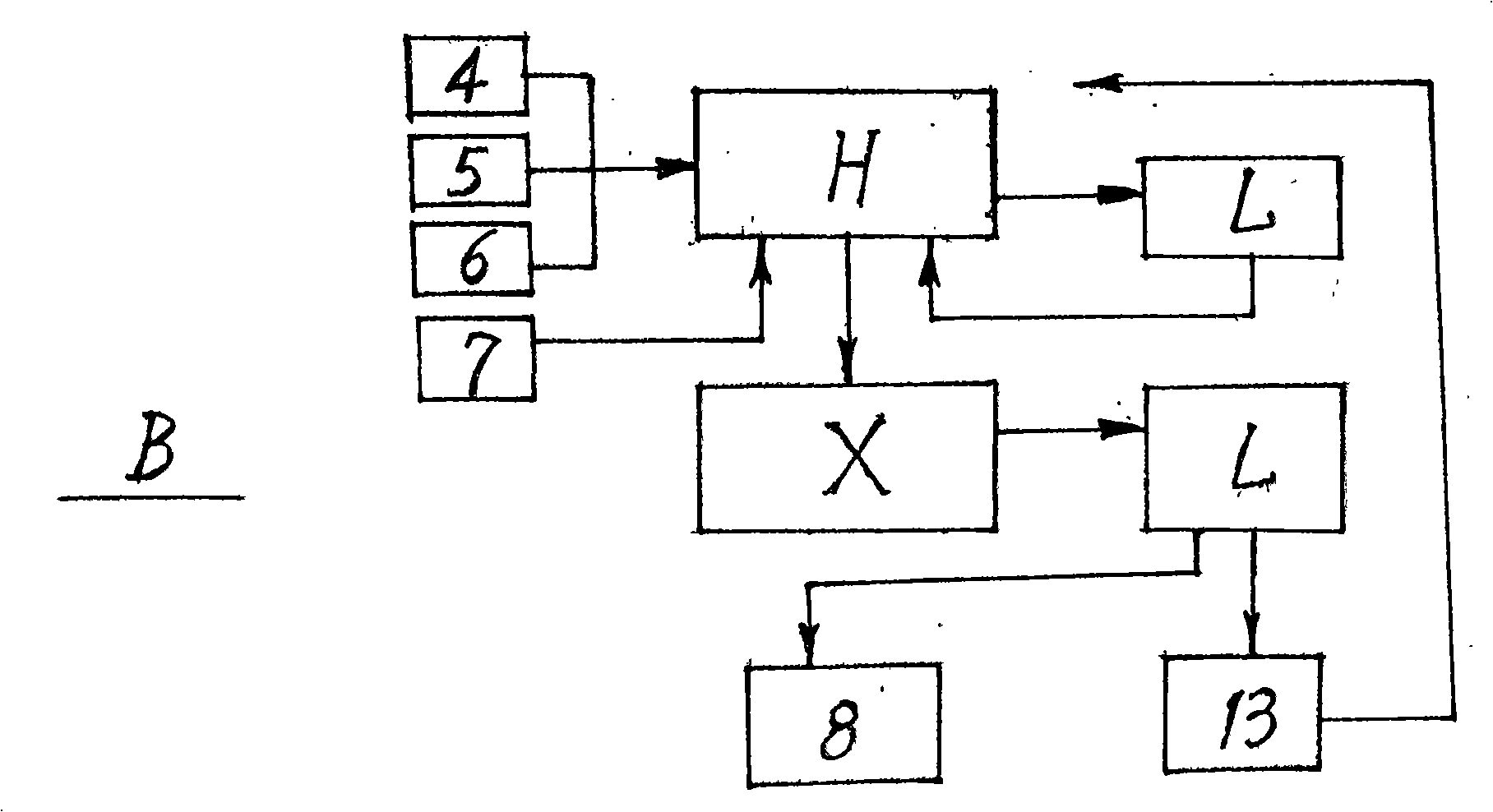

[0015] refer to figure 1 , the present invention takes L-phenylalanine 1 as the main raw material, through racemization process A, resolution process B, double salt crude product refining process C, refined salt dissolution reaction process D, finished product refining process E, respectively according to the variety and The solvent and auxiliary materials are added in doses, and the compound reaction is carried out under specific temperature, environment and time conditions, and D-phenylalanine 12 is finally formed. Add L-phenylalanine 1, solvent 2, and racemization agent 3 in the process of racemization process A, add pure water 4 after mixing, precipitate solvent 2 after racemization treatment, add ethanol 11 to wash after water distillation, and obtain DL -Phenylalanine6. Mix pure water 4 and hydrochloric acid 5 into a hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com