Functional tofu jelly powder and preparation method thereof

A functional and wet bean technology, applied in the field of soybean protein food and its production, can solve the problems of poor instant solubility, poor solubility, poor reduction gelation and the like, and achieve the effect of good instant solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] The preparation of No. 3 granulation solution is to mix No. 1 and No. 2 lecithin granulation solutions at a temperature of about 50°C with a chopping machine, and then homogenize them at a temperature of about 50°C with a pressure of 25Mpa, that is, The compound granulation liquid with a concentration of about 32%, namely No. 3 granulation liquid.

[0109] Calculated by making 100Kg of No. 3 granulation liquid with a concentration of 32%, 68% of which contains 68Kg of water, 2.5% of dry basis: 2.5Kg of lecithin, 2% of 2Kg of maltodextrin, and 0.5Kg of calcium and magnesium salt 0.5%, functional factor 27Kg accounted for 27%.

[0110] Granulation liquid of the present invention and preparation method thereof have following characteristics:

[0111] Feature 1: The maltodextrin added in the granulation liquid is a filler, which can adjust the protein content and functional factor content in the product. Increasing the maltodextrin will reduce the protein content, which ca...

Embodiment 1

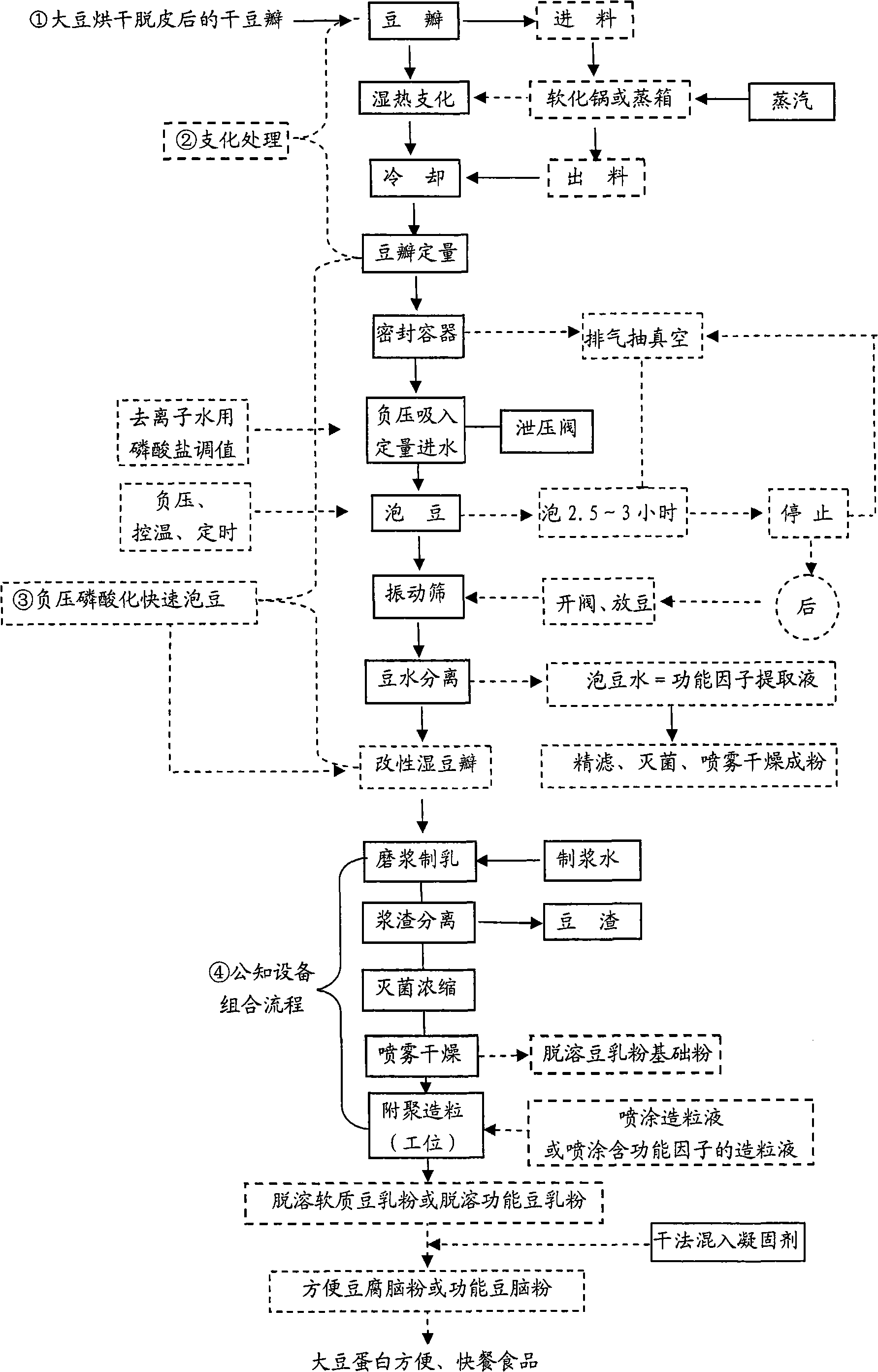

[0140] The preparation method 1 of embodiment 1-inactivating enzyme and removing fishy bean curd

[0141] according to figure 1 According to the technological process described in ②, the dehulled dry watercress is subjected to branching treatment with heat and humidity to obtain enzyme-inactivated (dry) watercress. The specific method is: put 40Kg of peeled dried watercress into a square net drawer with a height of 25mm, a length of 620mm, and a width of 420mm, put 10 drawers of dried watercress into a steamer, close the door of the box, let in steam, and keep 0.024Mpa steam pressure, in 95 ℃ hot and humid steam, heat for 5 minutes to carry out "damp heat branching treatment"; then close the valve to stop the steam, open the steam valve to release steam and pressure, then open the door of the steam box, take out the drawer, Quickly put the hot watercress into cold water of 4 times the weight of the watercress at about 20°C, stir intermittently and cool for 7 minutes, then dra...

Embodiment 2

[0143] Embodiment 2-The preparation method 2 of deactivating fishy bean curd

[0144] according to figure 1 According to the technological process described in ②, the dehulled dry watercress is subjected to branching treatment with heat and humidity to obtain enzyme-inactivated (dry) watercress. The specific method is: put 40Kg of peeled dried watercress into a square net drawer with a height of 25mm, a length of 620mm, and a width of 420mm, put 10 drawers of dried watercress into a steamer, close the door of the box, let in steam, and keep 0.025Mpa steam pressure, in the hot and humid steam of 96°C, heat for 5 minutes to carry out "damp heat branching treatment"; then close the valve to stop the steam, open the steam valve to release steam and pressure, then open the door of the steam box, take out the drawer, Quickly put the hot watercress into cold water of 5 times the weight of the watercress at about 20°C, stir intermittently and cool for 8 minutes, then drain the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com