Method for improving prolease activity of sauce daqu

A technology of protease and soybean whey protein, which is applied in the field of improving the activity of soy sauce Daqu protease, can solve problems such as unsatisfactory results, complicated process, uncertain safety issues, etc., to reduce the discharge of high-concentration organic wastewater and improve the activity of protease , Improve the effect of protein utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Concentrate the soaked soybean water to a protein content of 5%, add papain to hydrolyze it to a hydrolysis degree of 9%, keep at 90°C for 30 minutes to inactivate the enzyme, concentrate, and spray-dry to obtain soybean whey protein peptides. Among the obtained soybean whey protein peptides, the peptides with a molecular weight less than 3000Da accounted for 70.5% of the total nitrogen.

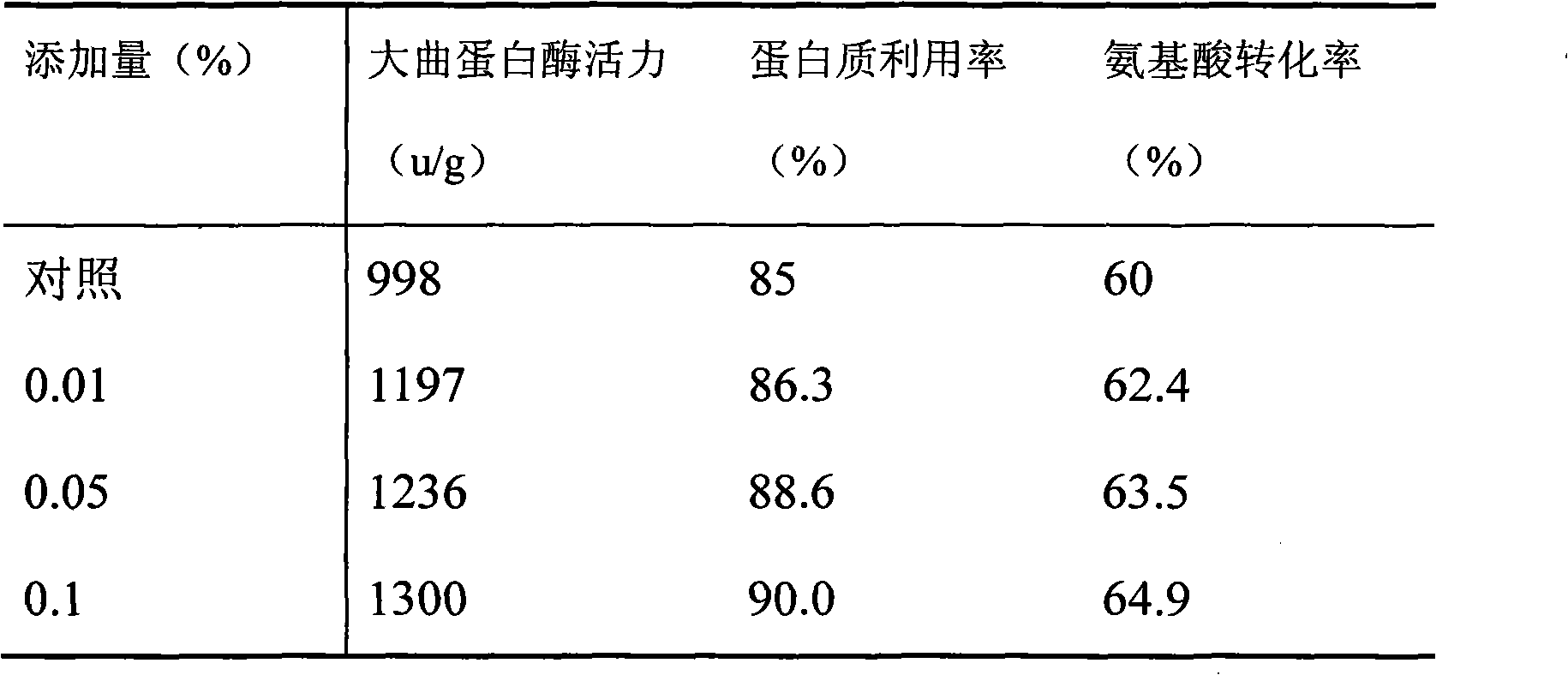

[0017] 2. Based on the weight of soybeans, after mixing 0.01% soybean whey protein peptides, 10% flour and 0.1% strains (Shanghai Niang 3042), they are evenly distributed on the cooked soybeans, and koji is made for 2 days. Temperature is 30 ℃, and relative humidity is 90%, soy sauce daqu is obtained, and its protease activity is 1150u / g. The obtained Daqu was fermented in open air, the recovery rate of soy sauce protein reached 86.3%, and the conversion rate of amino acid was 62.4%.

Embodiment 2

[0019] 1. Concentrate the soaked soybean water to a protein content of 8%, add trypsin to hydrolyze until the hydrolysis degree is 10%, keep at 93°C for 25 minutes to inactivate the enzyme, concentrate, and spray-dry to obtain soybean whey protein peptides. Among the obtained soybean whey protein peptides, the peptides with a molecular weight less than 3000Da accounted for 72.4% of the total nitrogen.

[0020] 2. Based on the weight of soybeans, mix 0.05% soybean whey protein peptides, 40% bran and 0.3% strains (Shanghai Niang 3042), evenly distribute them on the cooked soybeans, and make koji for 1 day , temperature is 35 DEG C, relative humidity is 60%, soy sauce Daqu is obtained, and its protease activity reaches 1236u / g. The obtained Daqu is subjected to open-air fermentation, the recovery rate of soy sauce protein reaches 88.6%, and the conversion rate of amino acid is 63.5%.

Embodiment 3

[0022] 1. Concentrate the soaked soybean water to a protein content of 10%, add papain to hydrolyze it to a hydrolysis degree of 12%, keep at 95°C for 20 minutes to inactivate the enzyme, concentrate, and spray-dry to obtain soybean whey protein peptides. Among the obtained soybean whey protein peptides, the peptides with a molecular weight less than 3000Da accounted for 75.8% of the total nitrogen.

[0023] 2. Based on the weight of soybeans, after mixing 0.1% soybean whey protein peptides, 80% flour and 0.6% strains (Shanghai Niang 3042), they are evenly distributed on the cooked soybeans, and koji is made for 3 days. Temperature is 25 ℃, relative humidity is 98%, soy sauce Daqu is obtained, and its protease activity reaches 1300u / g. The obtained Daqu was fermented in open air, the recovery rate of soy sauce protein reached 90.0%, and the conversion rate of amino acid was 64.9%.

[0024] Table 1 compares the method for improving the activity of soy sauce Daqu protease provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com