Preparation process of metallic carbide fine powder

A metal carbide and preparation technology, applied in the field of metal materials, can solve the problems of increased production energy consumption, slow reaction speed, high temperature requirements, etc., and achieve the effect of reducing the mixing of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

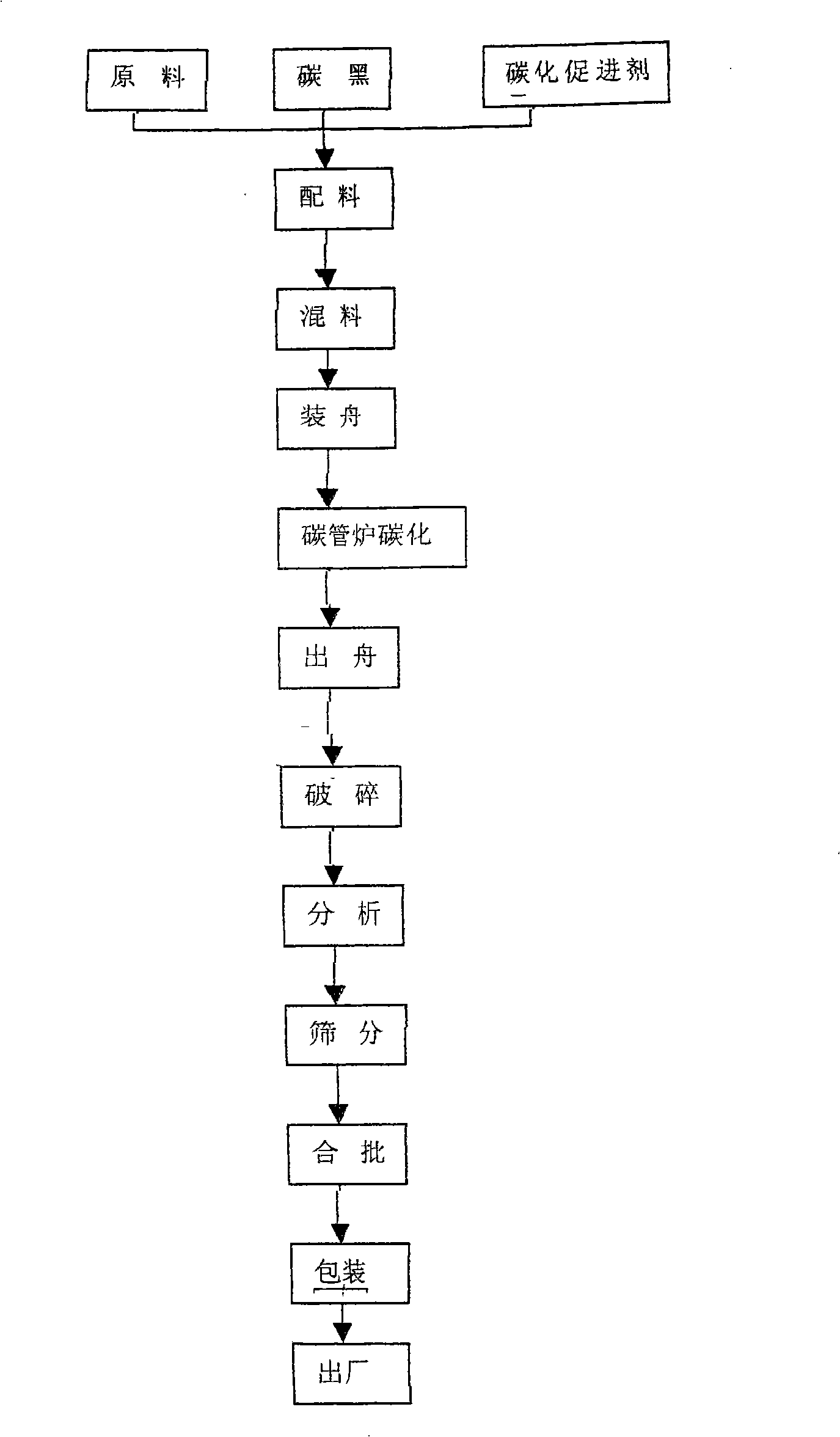

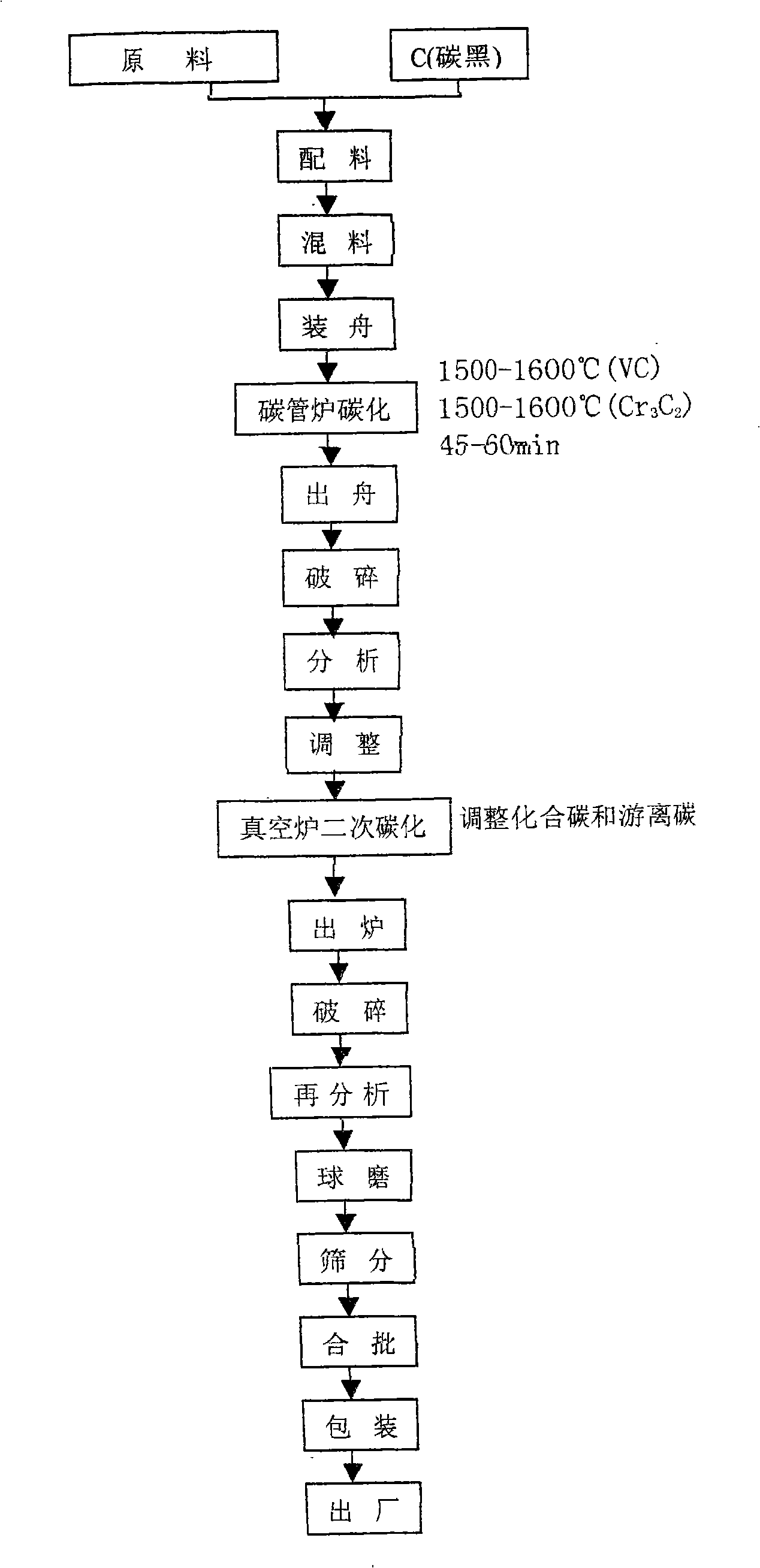

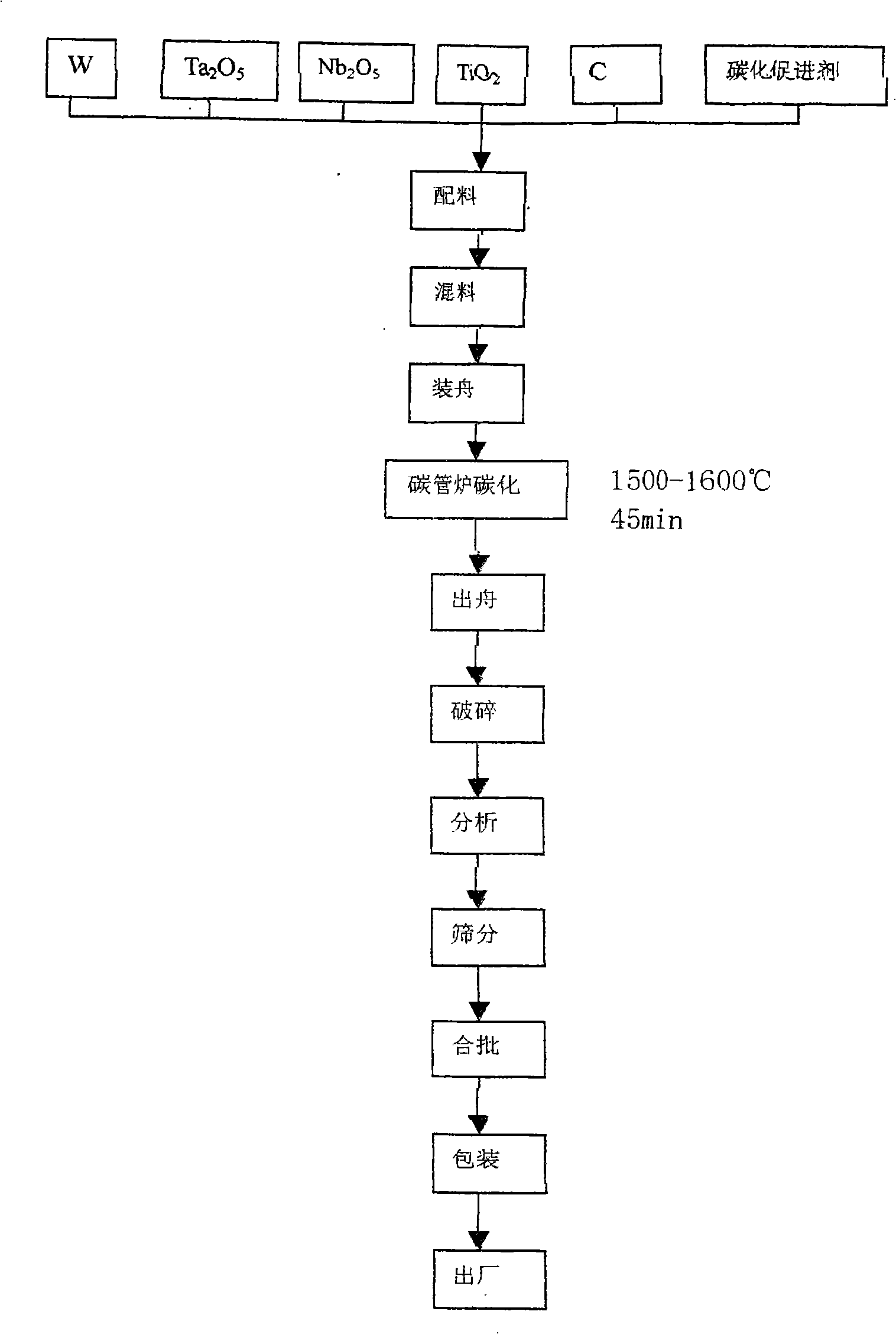

Method used

Image

Examples

Embodiment Construction

[0019] Product main technology and performance index table of the present invention

[0020] Grade

[0021] The present invention greatly improves the reaction speed and conversion rate by adding a carbonization accelerator in the carbonization reaction. The addition of carbonization accelerator can prepare carbide at lower temperature, and the particles of carbide produced are finer. The carbonization accelerator can accelerate the reaction rate because the carbonization accelerator preferentially participates in the reaction, changes the reaction pathway, and reduces the activation energy of the reaction; and its reaction product (carbide) is in a loose and porous state, which is conducive to diffusion The process is further carried out, thereby increasing the reaction rate and conversion rate. Compared with the general method, the carbonization reaction temperature is lowered by 300°C on average, which shortens the reaction time and reduces production energy cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com