Complete solid-state beam current type reinforcing steel corrosion monitoring sensor and method for producing the same

A technology for monitoring the corrosion of sensors and steel bars, applied in the field of sensors, can solve the problems of difficult determination of the working electrode WE area, deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

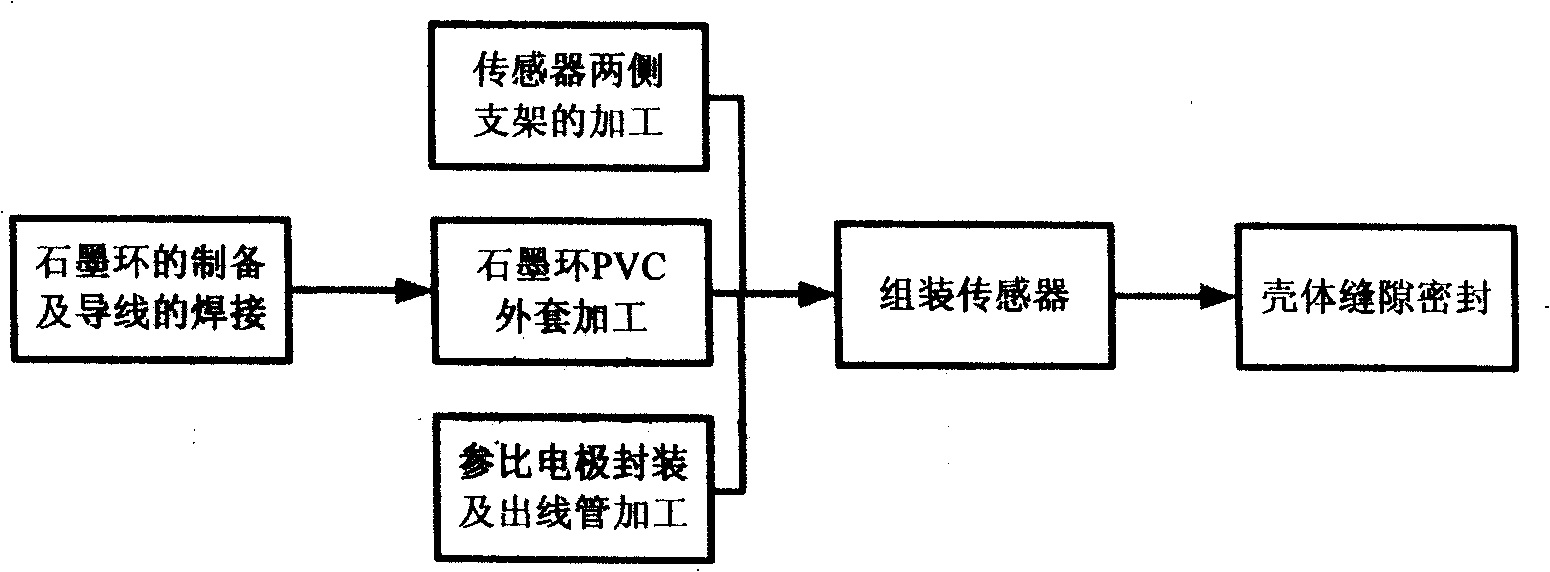

[0059] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0060] 1. Preparation of beam ring and wire welding

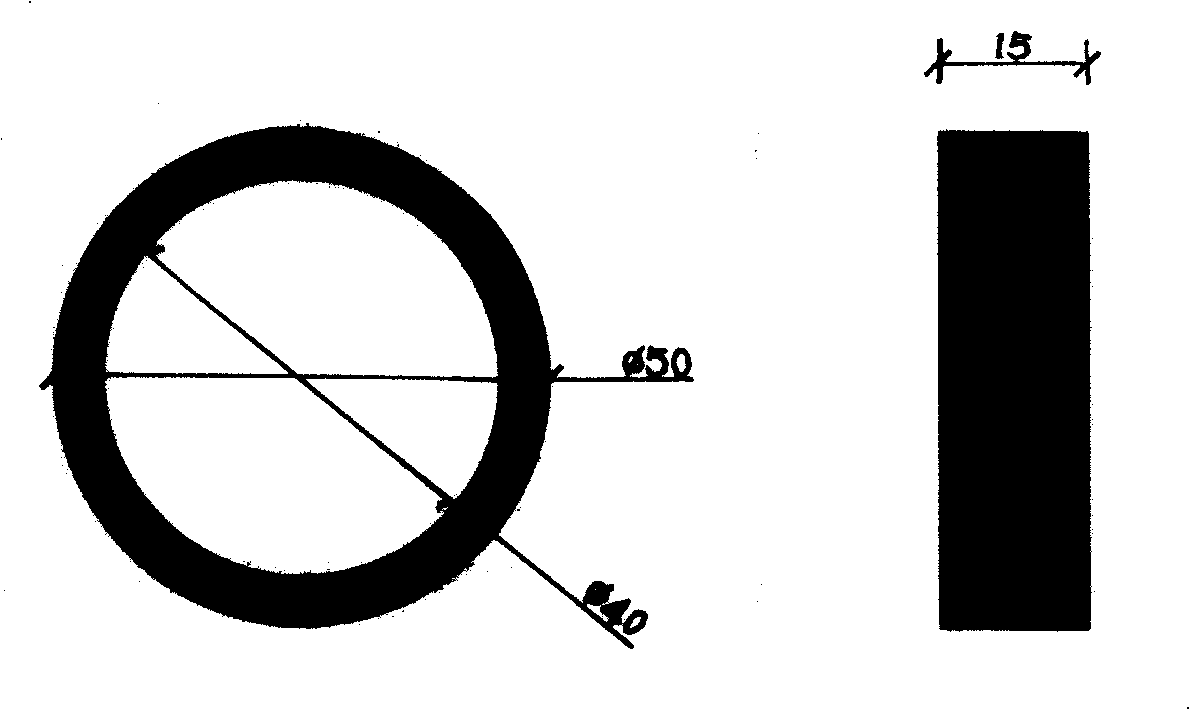

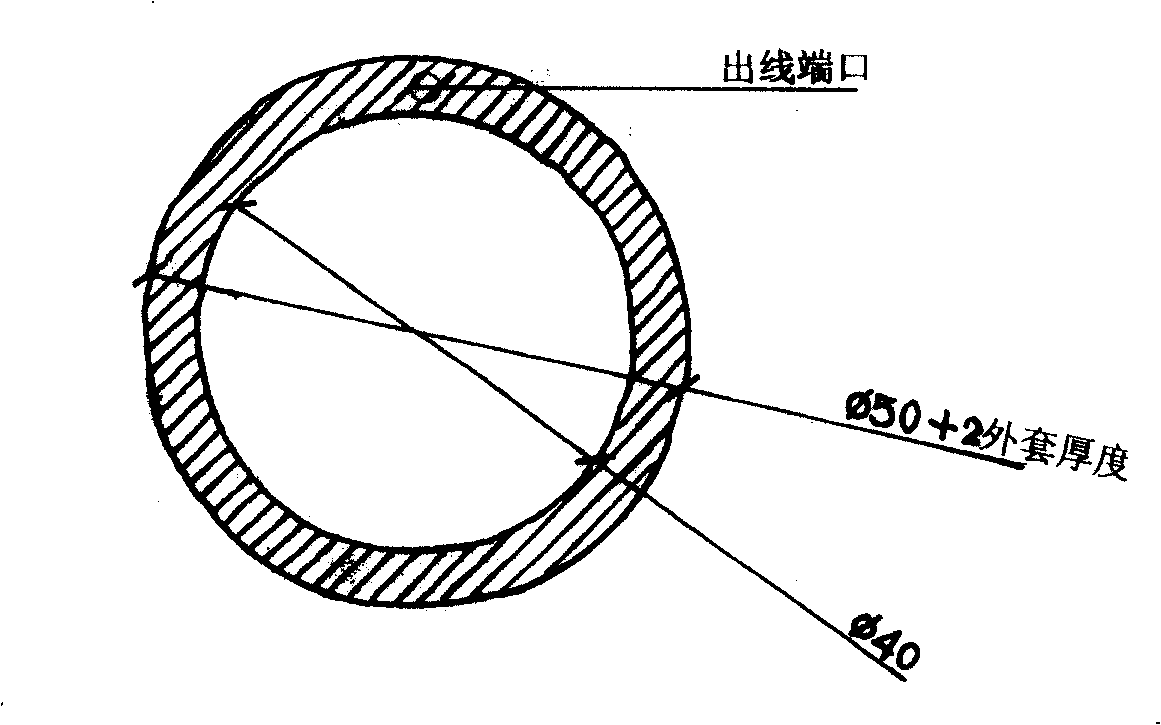

[0061] In this embodiment, the beam flow ring adopts graphite beam flow ring, and the specific size of the beam flow ring is shown in figure 2 , using mold compression molding. A hole with a diameter of 1 mm is drilled on the side wall of the pressed beam ring, and then the wire is tightly pressed into the hole with Cu powder to ensure good electrical conductivity. In addition, considering the sealing problem of the wire, first use AB glue to seal the connection between the wire and the beam ring, and then put the thermoplastic tube on the wire at the connection end of the wire and the beam ring. After heating, the thermoplastic tube is tightly pressed on the Outside the wire, the connection between the thermoplastic tube and the graphite is sealed again with AB glue, so as to ensure that the wire does not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com