Prescription of particles coated by butanoic acid derivative for feeding and preparing technique thereof

A butyric acid derivative and production process technology, applied in the fields of application, animal feed, animal feed, etc., can solve the problems of deliquescence, unfavorable storage, caking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] Attached table 2. The particle size distribution of embodiment 2 (butaline 30)

[0041] <20 mesh

20-30 mesh

30-40 mesh

40-60 mesh

60-100 mesh

>100 mesh

1.4%

1.6%

3.0%

63.4%

30%

0.6%

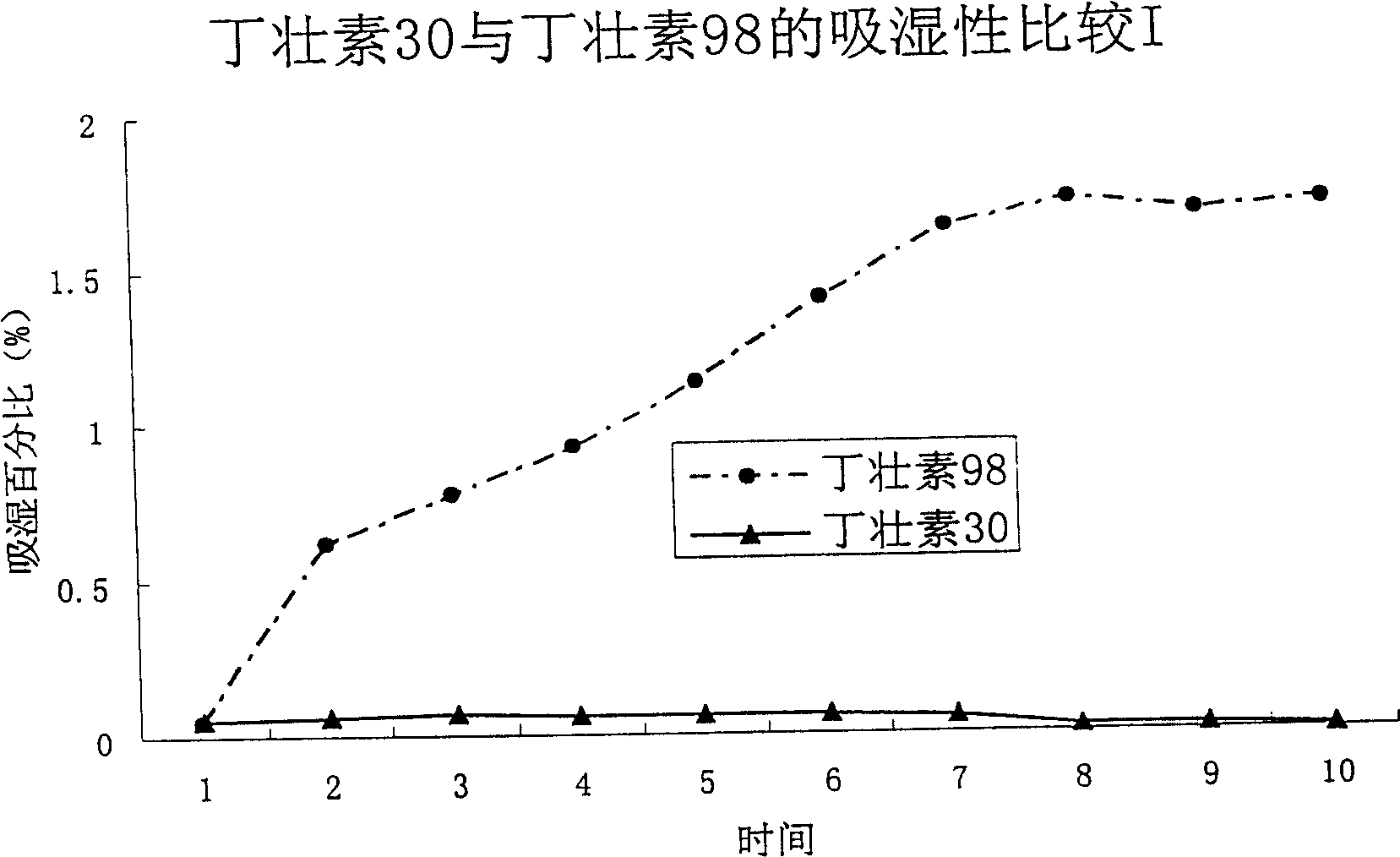

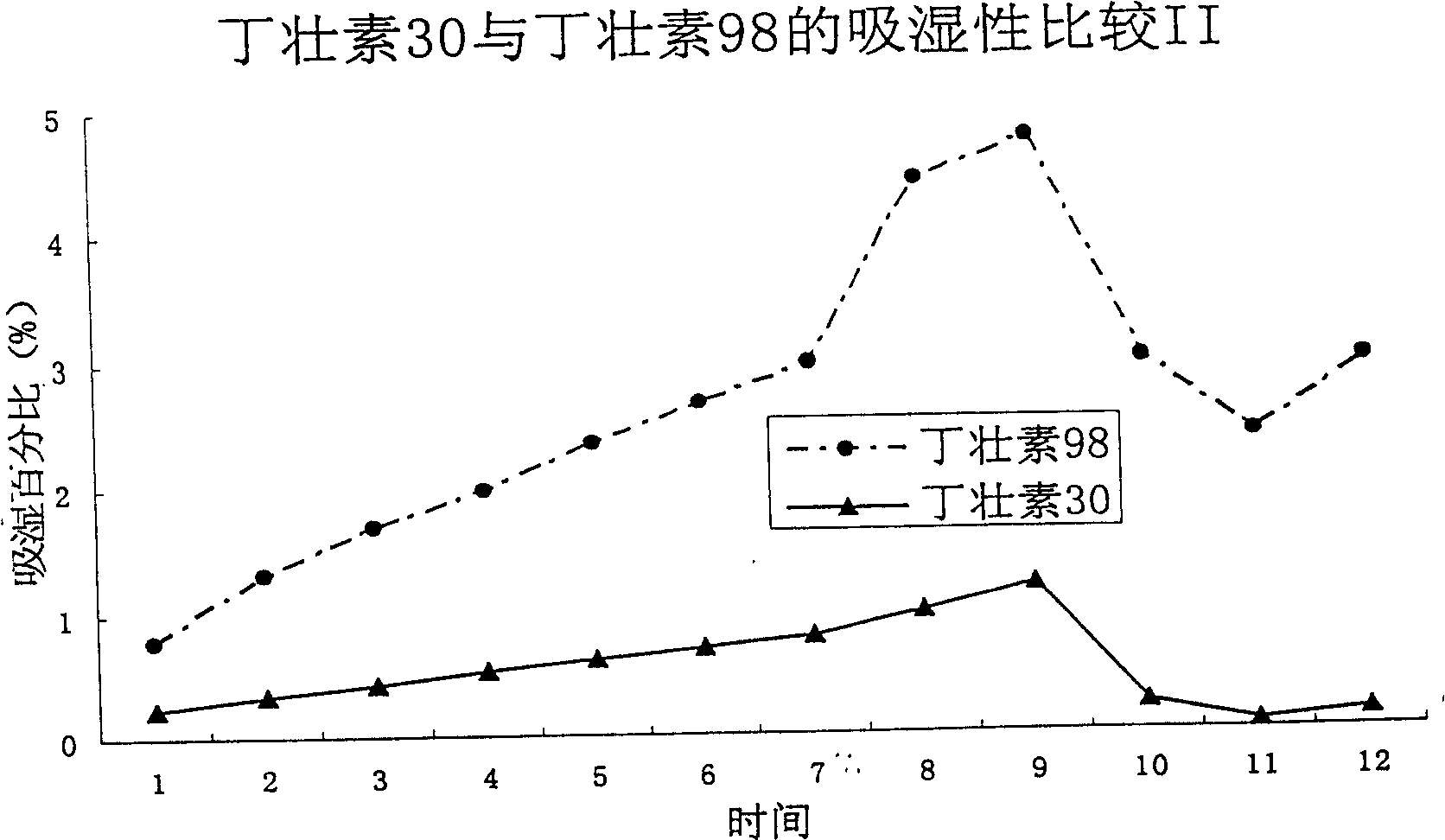

[0042] See attached table 3, shown in 4, be the comparison of the hygroscopicity of embodiment 2 (Diatron 30) and 98% sodium butyrate former powder (Diatron 98).

[0043] Attached table 3. embodiment 2 (butaline 30) and

[0044] Hygroscopicity comparison I of sodium butyrate (butyroxine 98)

[0045] time

(min)

Air humidity(%)

Butyroxine 30 hygroscopic

Ratio (%)

Dingzhuangsu 98 hygroscopic

Ratio (%)

10

78

0.050

0.0420

20

78

0.060

0.610

30

78

0.070

0.770

[0046] 40

78

0.060

0.920

60

78

0.060

1.120

80

78

0.060 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com