Preparation method and use of silicon carbide nano-wire catalyst for making hydrogen

A technology of silicon carbide nanowires and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve problems such as few reports on photolysis of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix silicon powder and silicon dioxide (the molar ratio is 1:1) and evenly place it on the bottom of the graphite crucible, spread a layer of carbon nanotube powder on the surface of the mixture of silicon powder and silicon dioxide, and cover the graphite crucible Put a lid made of graphite flakes into a high-temperature vacuum sintering furnace, evacuate to 0.1Pa, fill with argon protection, heat to 1500°C, and keep at this temperature for 6 hours. After the heat preservation was over, the heating power was turned off, and the furnace was naturally cooled to room temperature under the condition of circulating water cooling, and the sintering furnace was opened to take out the sample, and it was found that the black carbon nanotubes inside the crucible had turned into a layer of light green product.

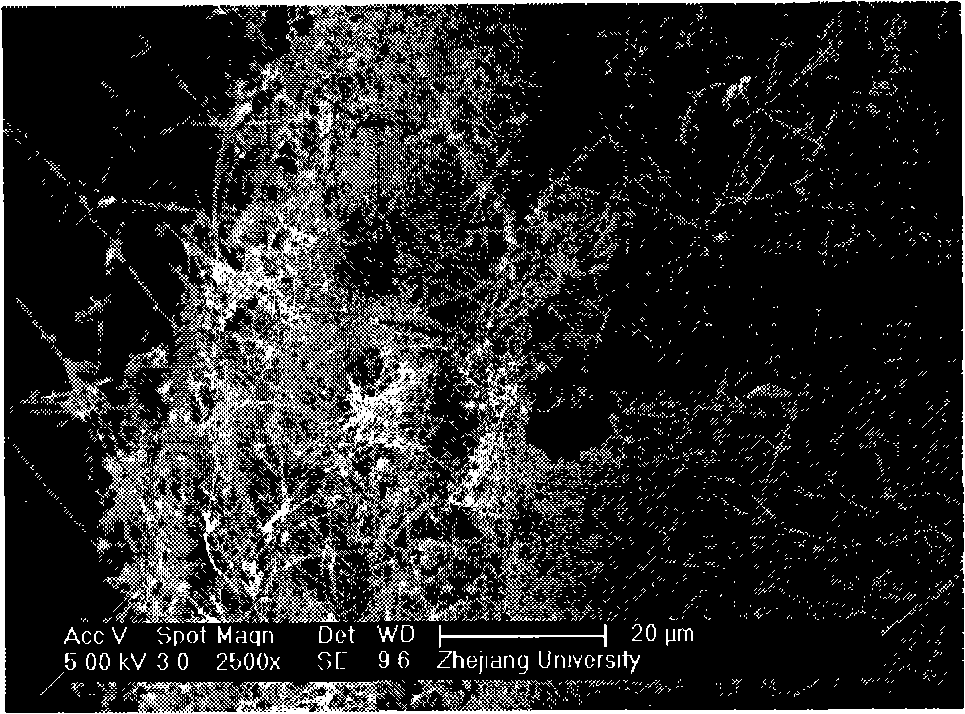

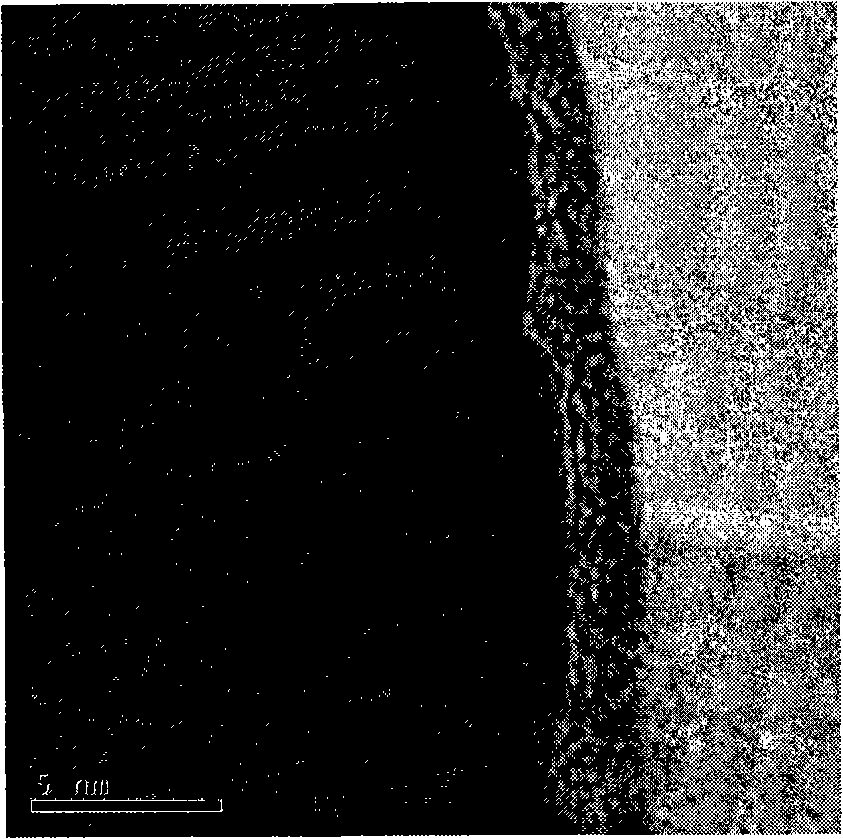

[0021] X-ray diffraction and energy spectrum analysis showed that the product was β-SiC nanowires. The product was placed under a field emission scanning electron microsc...

Embodiment 2

[0024] Mix silicon powder and silicon dioxide (the molar ratio is 1:1) and evenly place it on the bottom of the graphite crucible, spread a layer of carbon nanotube powder on the surface of the mixture of silicon powder and silicon dioxide, and cover the graphite crucible Put a lid made of graphite flakes into a high-temperature vacuum sintering furnace, evacuate to 10Pa, fill with argon protection, heat to 1100°C, and keep at this temperature for 10 hours. After the heat preservation was over, the heating power was turned off, and the furnace was naturally cooled to room temperature under the condition of circulating water cooling, and the sintering furnace was opened to take out the sample, and it was found that the black carbon nanotubes inside the crucible had turned into a layer of light green product. X-ray diffraction and energy spectrum analysis showed that the product was β-SiC nanowires. The morphology of the product was observed under a field emission scanning elect...

Embodiment 3

[0027] Mix silicon powder and silicon dioxide (the molar ratio is 1:1) and evenly place it on the bottom of the graphite crucible, spread a layer of carbon nanotube powder on the surface of the mixture of silicon powder and silicon dioxide, and cover the graphite crucible A lid made of graphite flakes is placed in a high-temperature vacuum sintering furnace and vacuumed to 10 -3Pa, filled with argon protection, heated to 1600°C, and kept at this temperature for 1 hour. After the heat preservation was over, the heating power was turned off, and the furnace was naturally cooled to room temperature under the condition of circulating water cooling, and the sintering furnace was opened to take out the sample, and it was found that the black carbon nanotubes inside the crucible had turned into a layer of light green product. X-ray diffraction and energy spectrum analysis showed that the product was β-SiC nanowires. The product was placed under a field emission scanning electron mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com