Heat resisting fluororubber composition and sulfidization molding products thereof

A fluororubber and composition technology, applied in the field of heat-resistant fluororubber compositions and their vulcanized molded products, can solve the problems of limited supply, high price of perfluororubber, attenuation of physical properties of rubber, etc., and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

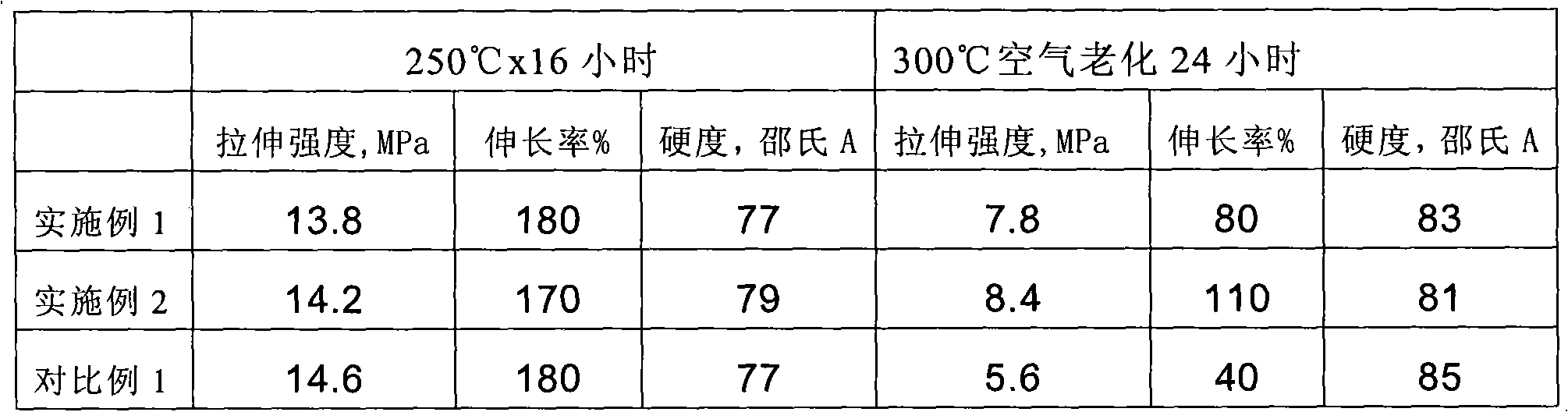

[0034]In 100 grams of vinylidene fluoride (VDF) / hexafluoropropylene (HFP) copolymer (trade name FE2603, Mooney viscosity ML1+10, 121 ° C = 70), add 2 grams of polyol-based vulcanizing agent bisphenol A F ( Trade name is BF6), 0.5 grams of quaternary phosphorus salt (trade name is BPP, vulcanization accelerator), 3 grams of magnesium oxide, 6 grams of calcium hydroxide, 30 grams of thermal carbon black (trade name is N990) and 1 gram of oxide cerium. The mixture was kneaded at room temperature for 20 minutes using an open rubber mixer to obtain a composition for vulcanization.

[0035] Next, use a metal mold plated with hard chromium, pressurize and vulcanize for 10 minutes under the conditions of a pressurized pressure of 25 tons and a pressurized temperature of 170°C, and process and form a 150x150x2mm test piece, and test it after two-stage vulcanization at 250°Cx16 hours Tensile Strength, % Elongation and Hardness. After aging in air at 300°C for 24 hours, the above-menti...

Embodiment 2

[0037] Except for adding 5 grams of cerium oxide, the fluororubber composition was prepared in the same manner as in Example 1, and its various properties were tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com