Liquified sand foundation anti-vibration processing method

A sandy soil foundation and treatment method technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problem of difficulty in ensuring the continuity and integrity of vertical drainage channels, affecting the consolidation effect of the soil layer, and soil disturbance , uplift, lateral shift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

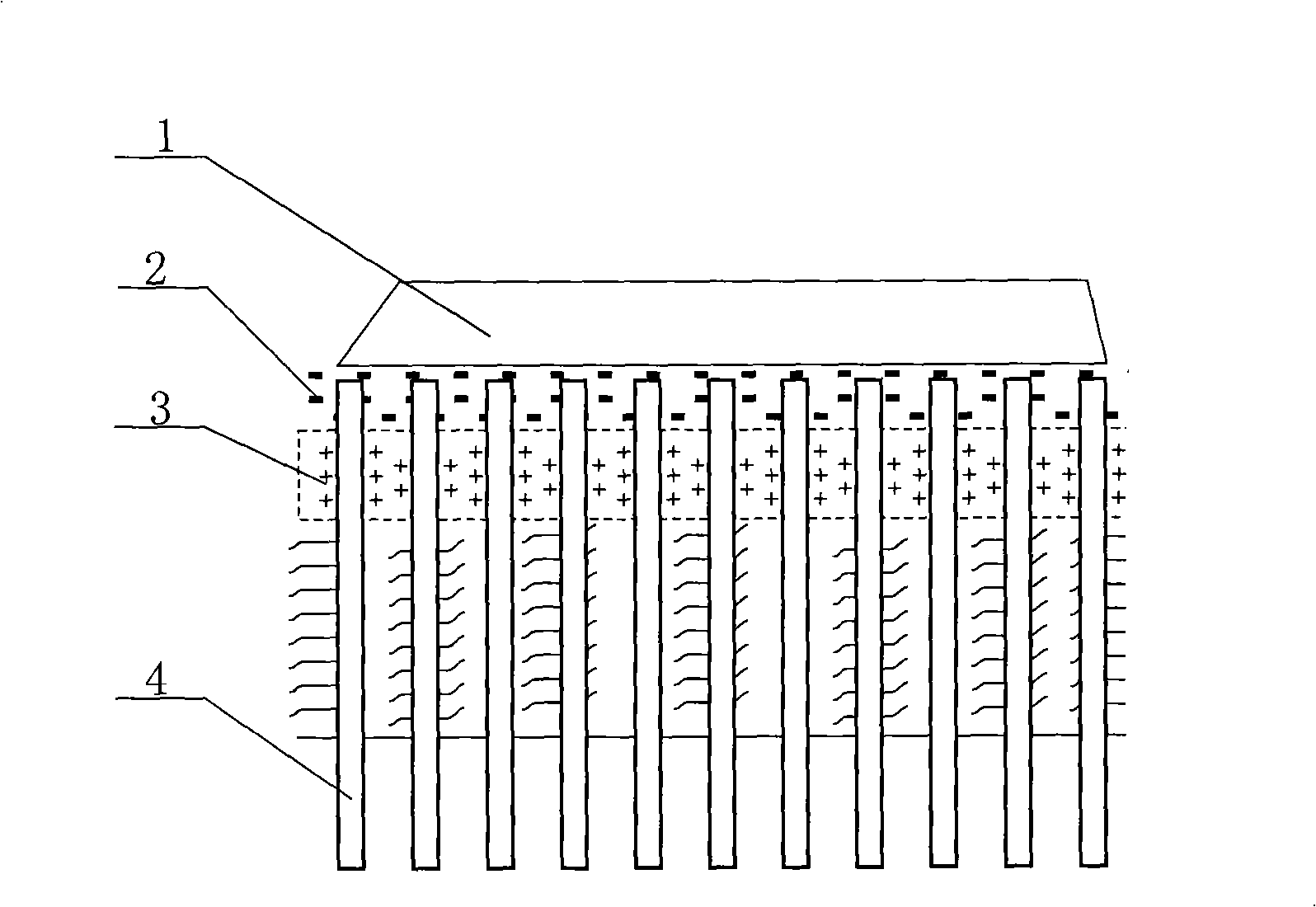

Embodiment 1

[0033] Shanjie Expressway adopts the anti-seismic treatment method of liquefiable sand foundation of the present invention, wherein the reinforced vertical drainage body adopted in the dynamic method is a bagged sand well, and the bagged sand well is arranged in a plum blossom shape, and the diameter of the casing is increased to The conventional 1.8 times; the spacing is reduced to 0.6 times of the conventional; the diameter of the bagged sand well is increased to 1.2 times of the conventional The spacing is 1m. The static method is surcharge preloading, which is carried on the liquefiable sand foundation with bagged sand wells. The surcharge material is earthwork. The overload is 1m, and the preloading period is more than 6 months. After the application of the present invention, the foundation of the Shanjie Expressway section has been effectively reinforced, and the preloading preloading has also reduced the post-construction settlement of the foundation soil, and the accep...

Embodiment 2

[0035] The Guangzhu West Line adopts the anti-seismic treatment method of liquefiable sand foundation of the present invention, wherein the reinforced vertical drainage body adopted in the dynamic method is a bagged sand well, and the bagged sand well is arranged in a square shape, and the diameter of the casing is increased to The conventional 1.9 times, the spacing is reduced to 0.6 times of the conventional, the diameter of the bagged sand well is increased to 1.0 times of the conventional, the diameter of the casing for drilling the bagged sand well is 140mm, the diameter of the bagged sand well is 7cm, and the sand well is specific The spacing is 0.8m. The static method is surcharge preloading, which is carried on the liquefiable sand foundation with bagged sand wells. The surcharge material is earthwork, the height of the subgrade filling is 7m, and most road sections are 1m equal load preloading. Partial road sections are overloaded by 2m, and the preloading period is 6...

Embodiment 3

[0037] The Guanghe high-speed test section adopts the anti-seismic treatment method of liquefiable sandy soil foundation of the present invention, wherein the reinforced vertical drainage body adopted in the dynamic method is a bagged sand well, and the bagged sand well is arranged in a plum blossom pattern, and the diameter of the casing is increased. It is 2 times larger than the conventional one, the spacing is reduced to 0.8 times the conventional one, and the diameter of the bagged sand well is adjusted to 1.3 times the conventional one. The specific casing diameter for drilling bagged sand wells is 170mm, the diameter of bagged sand wells is 7cm, and the specific spacing of sand wells is 0.8m; compaction technology is also used to intersperse compacted empty wells between bagged sand wells, The spacing between empty wells is 0.6m. The static method is surcharge preloading, which is carried on the liquefiable sand foundation with bagged sand wells. The surcharge material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com