Nonmagnetic Strength-toughen stainless steel and method for manufacturing same

A manufacturing method and toughening technology, applied in manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of poor corrosion resistance, low processing strength and hardening coefficient, unstable blank quality, etc., and achieve deformation and deformation. Uniform temperature, uniform and dense internal metallurgical quality, good dimensional accuracy and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

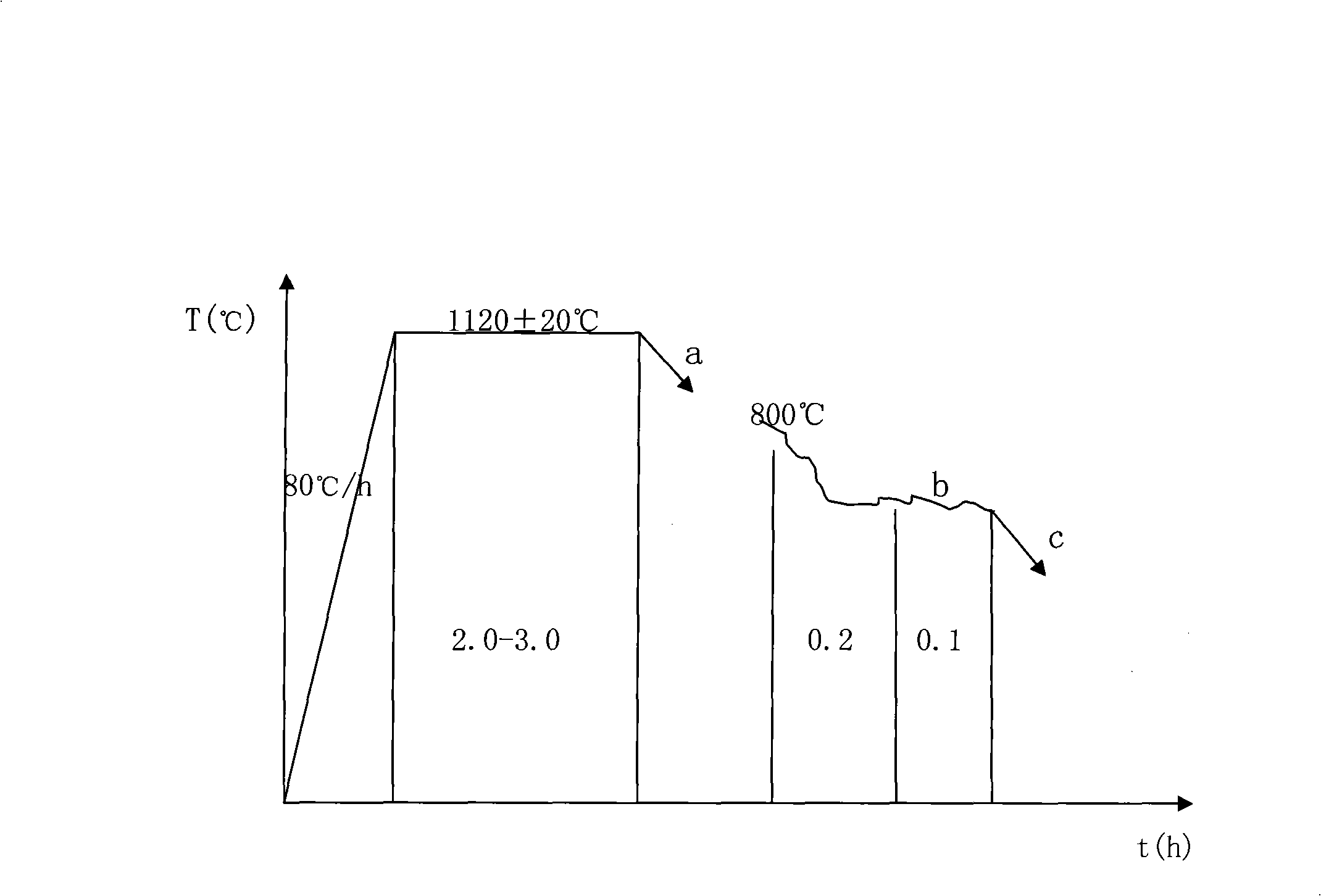

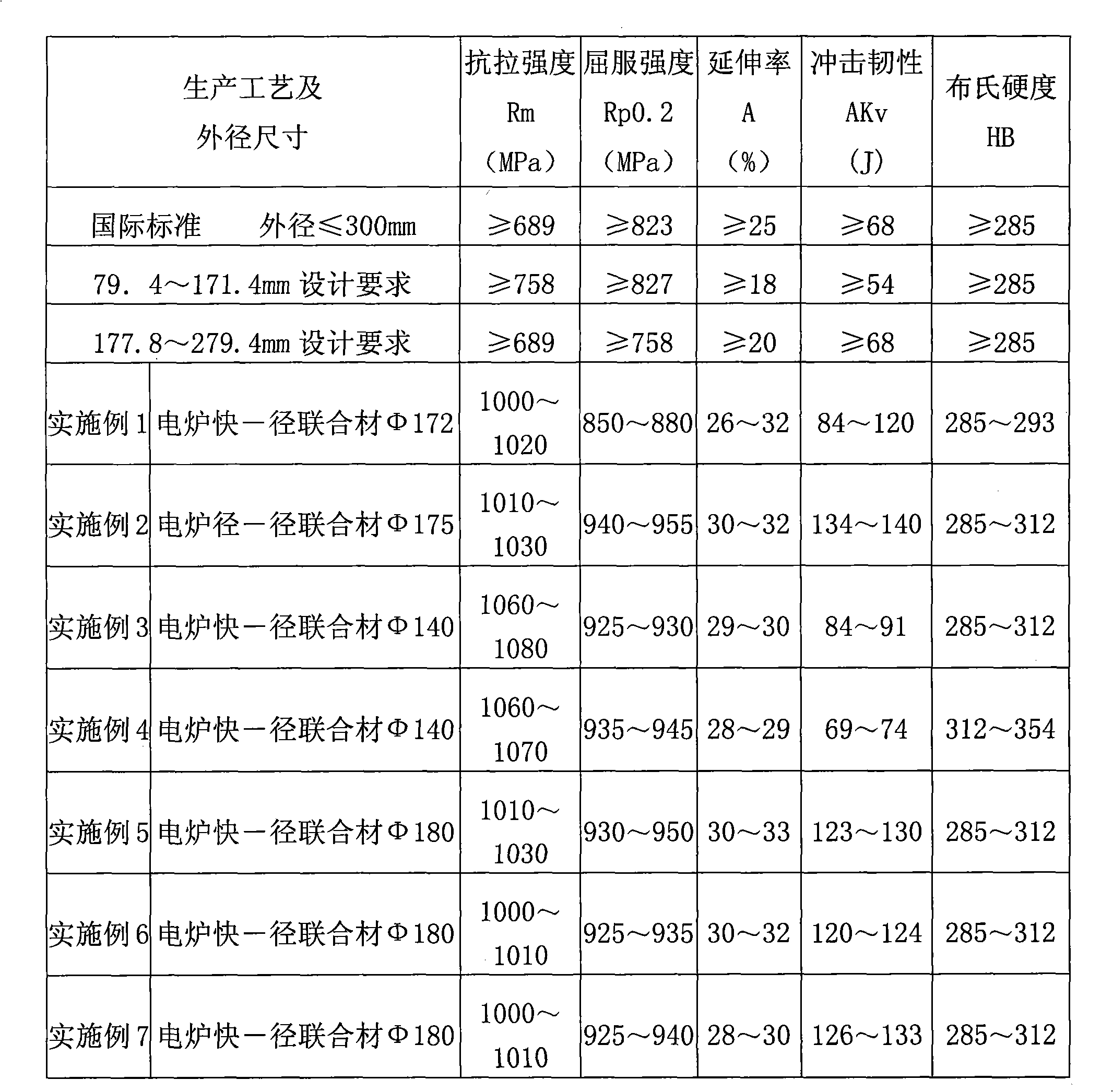

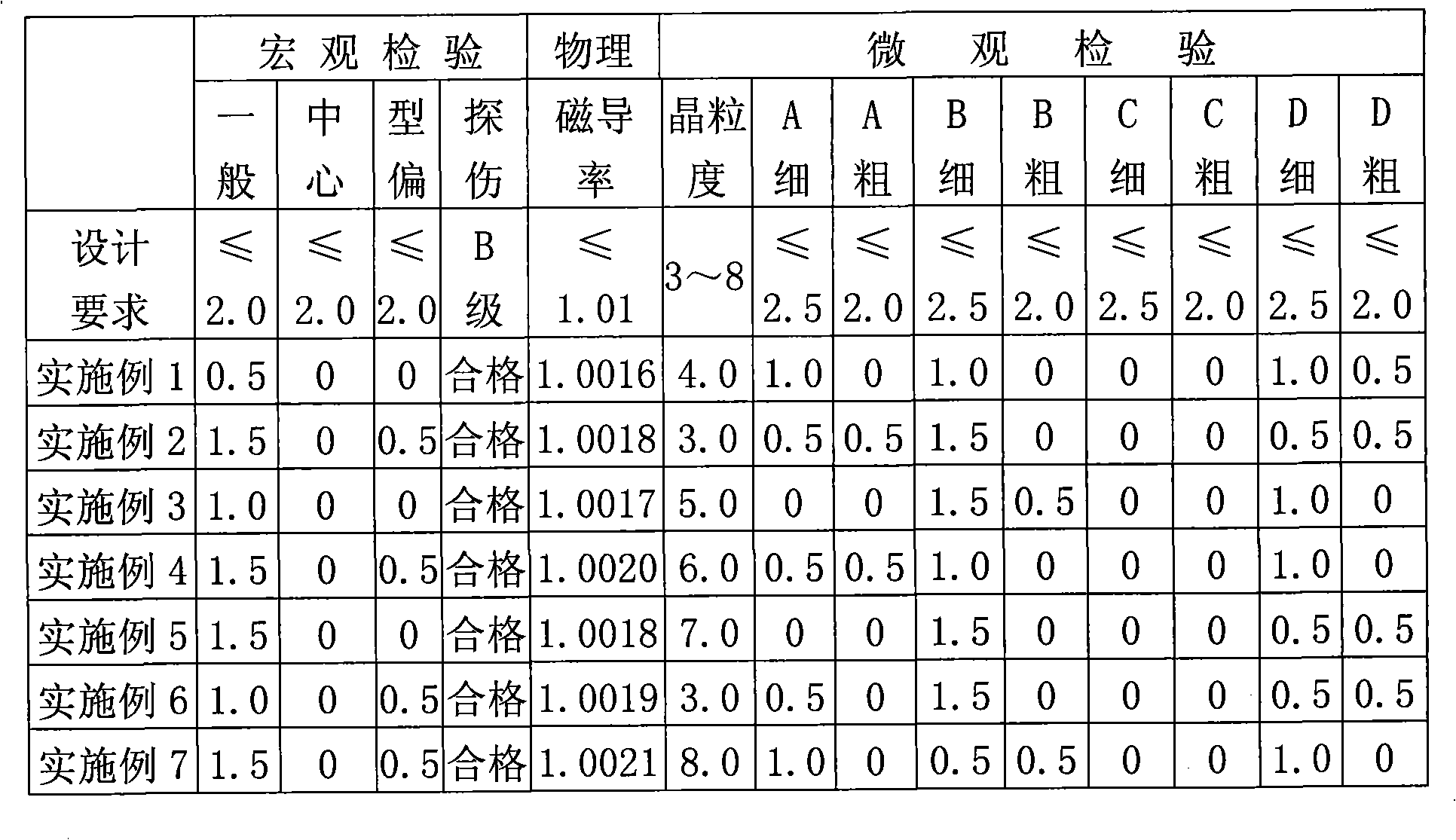

[0047] Stainless steel is smelted according to the chemical composition shown in Table 3, and the smelting adopts electric furnace-AOD refining-LFV refining or electric furnace-LFV refining. After the ingot is directly formed in the electric furnace, the steel ingot is heated at high temperature by rapid forging or radial forging, and the billet is surface-finished and then formed by a radial forging machine. Such as figure 1 As shown, in the process of radial forging, the steel billet is first heated to 1120±20°C, the heating rate is 80°C / hour, the holding time is 2 to 3 hours, and then the pre-forging with 80% deformation ( figure 1 After section a) in ), stop forging until the temperature drops to 800°C for about 0.2 hours, and then carry out radial forging with 20% deformation under the condition of not higher than 800°C ( figure 1 Section b in), about 0.1 hour or so. The forged steel is naturally cooled in the air ( figure 1 in paragraph c).

[0048] Table 3 The chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com