Ultra high vacuum magnetron sputtering rectangular plane sputtering target

A magnetron sputtering and ultra-high vacuum technology, which is applied in the field of magnetron sputtering targets, can solve the problems of safe fixation of sputtering targets, poor solderability, affecting the performance and yield of semiconductor devices and circuits, etc., to reduce costs, Overcoming the effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

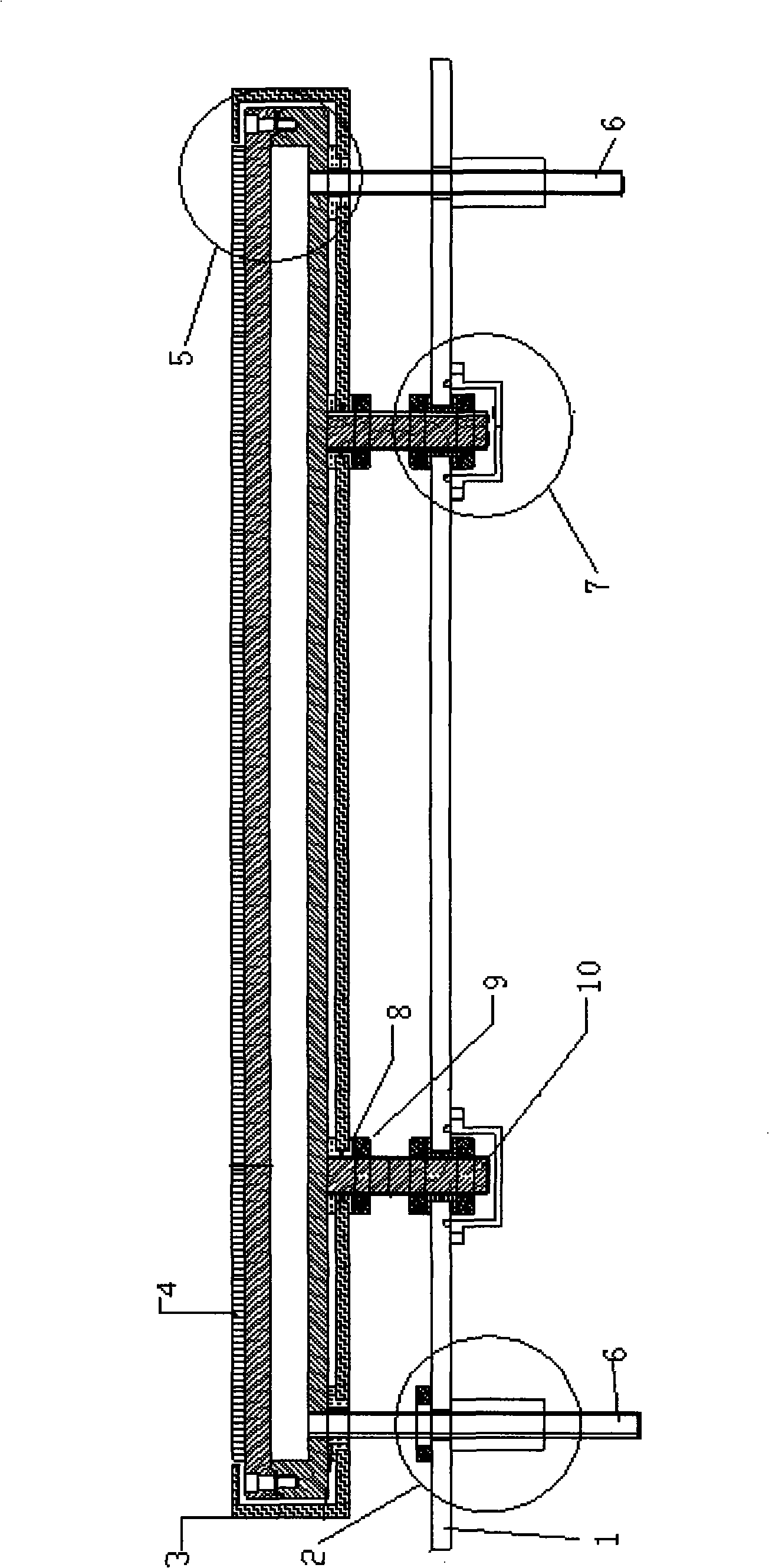

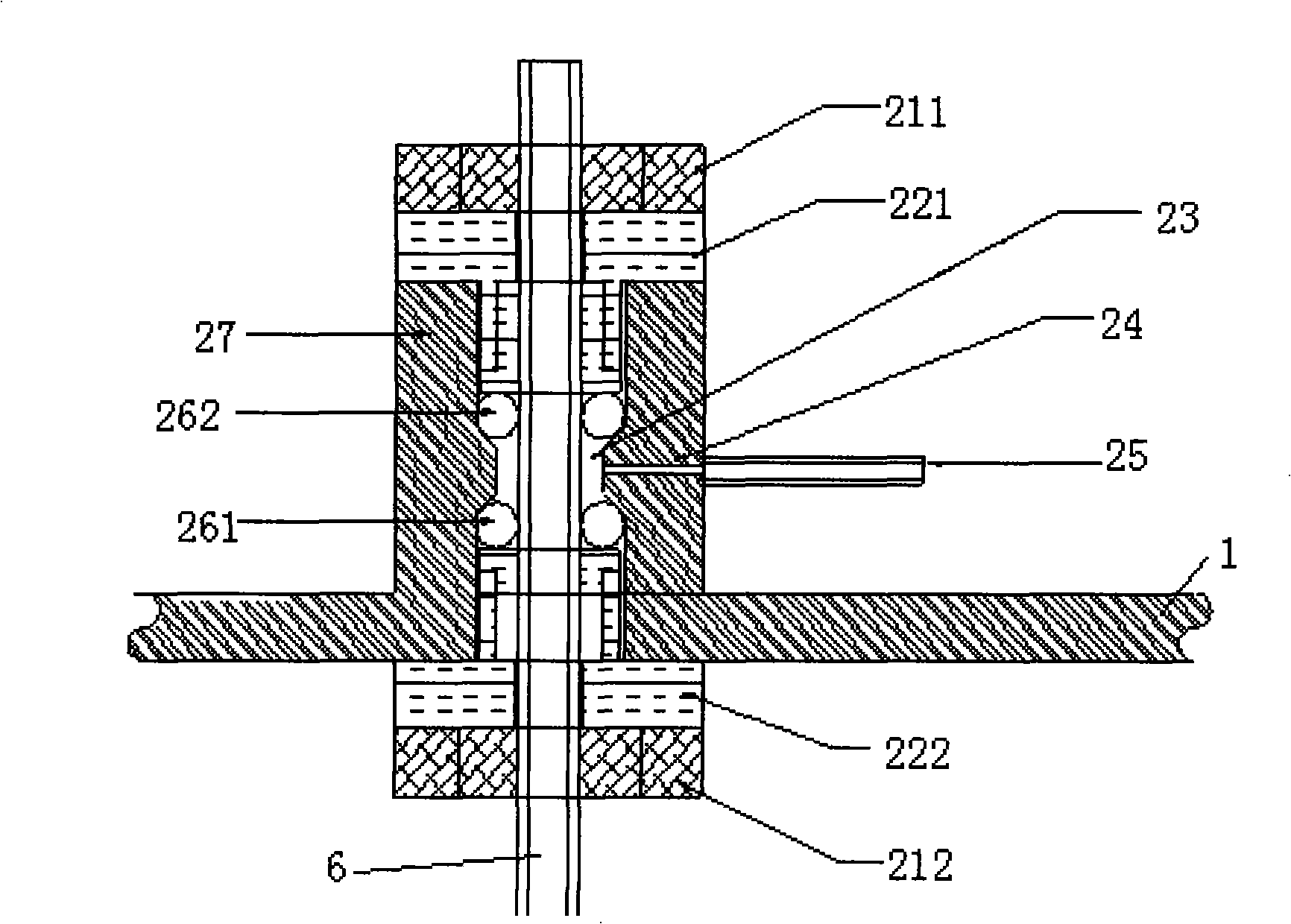

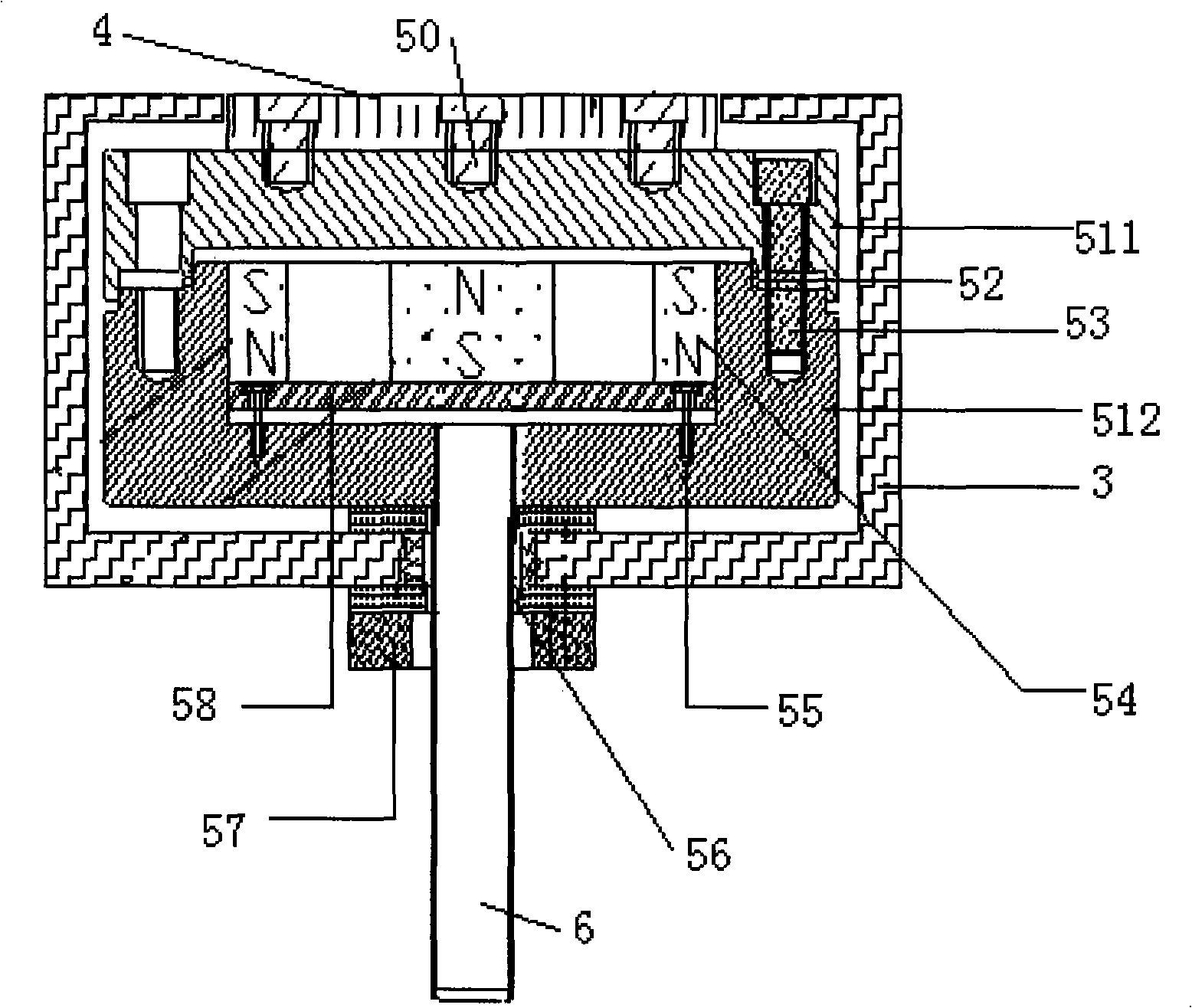

[0014] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, the water-cooled cavity part 5 located in the target shield 3 is respectively connected with the cooling water pipe 6 and the support screw 10, and the cooling water pipe 6 and the support screw 10 are respectively connected with the mounting flange 1 through the cooling water pipe sealing part 2 and the supporting screw sealing part 7 connect. The specific connections are as follows: the two end faces of the inner cavity neck of the flange boss 27 of the cooling water pipe sealing part 2 are respectively equipped with O-shaped sealing rings (262, 261) and insulating sleeves which are sleeved on the outside of the cooling water pipe 6. Gaskets (221, 222), wherein the O-shaped sealing rings (261, 262) are O-type fluorine rubber rings, and now it is preferred that the O-shaped fluorine rubber rings be Viton-type fluorine rubber rings. The upper tightening nut 211 and the lower tightening nut 212 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com