Method for plating copper on surface of carbon nanotube

A technology of carbon nanotubes and copper plating, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of long process route, difficult operation, high cost, etc., achieve simplified process, convenient operation, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

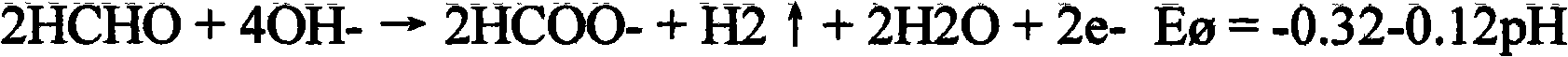

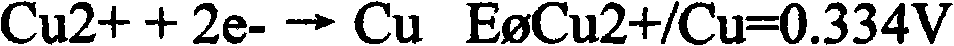

Method used

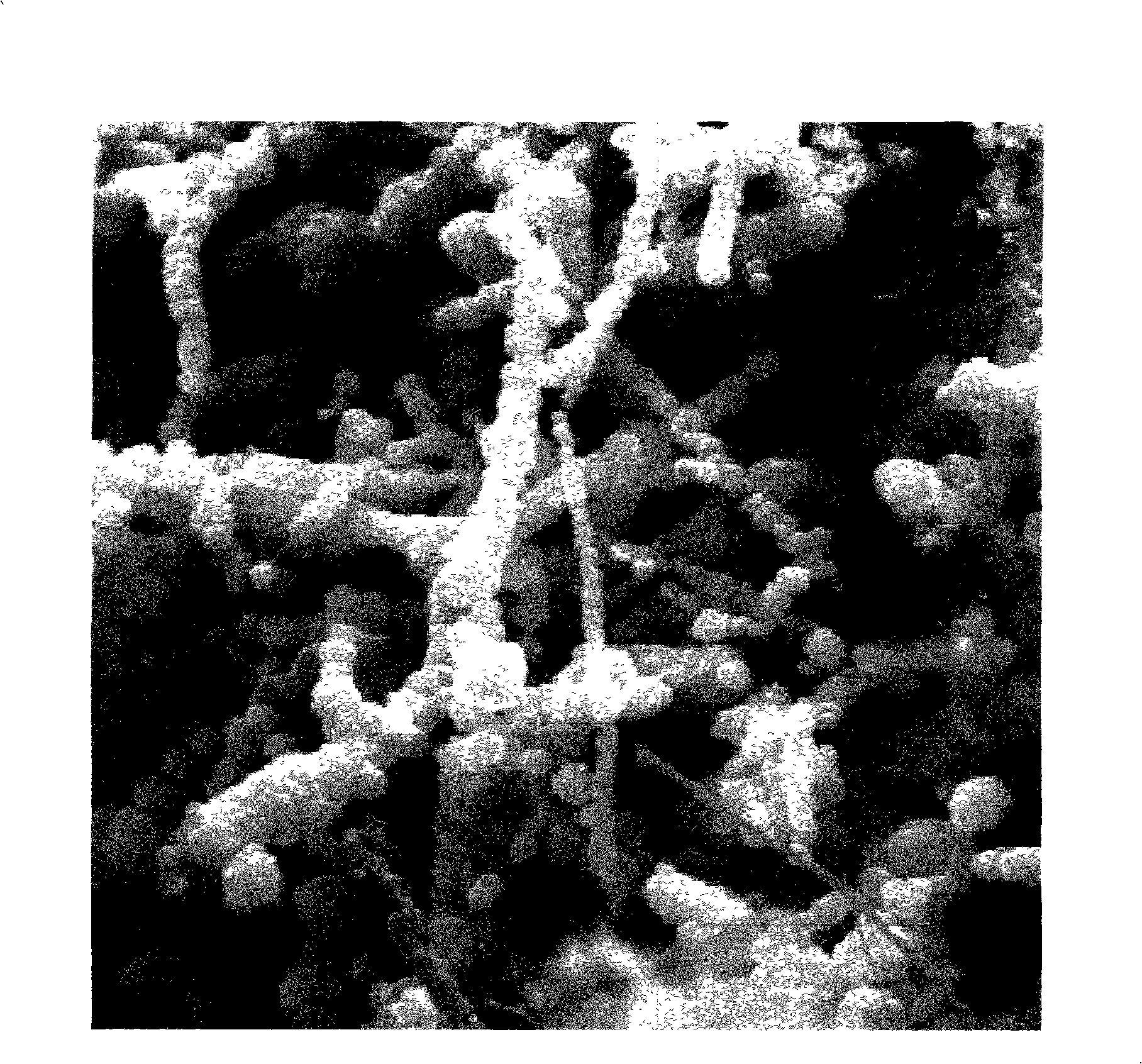

Image

Examples

Embodiment 1

[0044] The preparation method of copper plating on the surface of carbon nanotubes in this embodiment adopts Cu2+ as the source of elemental copper, and the reducing agent is Zn; its main reagents are CuSO4 5H2O, Zn powder, glycerol, ethylene glycol, potassium sodium tartrate, FeSO4 7H2O, HNO3; the concentration requirement of Cu2SO4·5H2O is 6.5g / l, the concentration requirement of glycerol is 133ml / l, the concentration requirement of ethylene glycol is 90ml / l, the concentration requirement of potassium sodium tartrate is 8.5g / l l, the concentration of FeSO4 7H2O is required to be 3.5g / l, the concentration of zinc powder is required to be 1.85g / l; the process conditions are as follows: the reaction time is 1 hour, the reaction temperature is 0-25°C, and the complexing agent is glycerol , ethylene glycol, and potassium sodium tartrate are used in combination, and the additive Fe2+ (FeSO4) is added to the plating solution;

[0045] The preparation method of the copper plating on...

Embodiment 2

[0049] The preparation method of copper plating on the surface of carbon nanotubes in this embodiment adopts Cu2+ as the source of elemental copper, and the reducing agent is Zn; its main reagents are CuSO4 5H2O, Zn powder, glycerol, ethylene glycol, potassium sodium tartrate, FeSO4 7H2O, HNO3; the concentration requirement of Cu2SO4·5H2O is 6.0g / l, the concentration requirement of glycerol is 125ml / l, the concentration requirement of ethylene glycol is 85ml / l, the concentration requirement of potassium sodium tartrate is 8.0g / l l, the concentration of FeSO4 7H2O is required to be 3.0g / l, and the concentration of zinc powder is required to be 1.80g / l; the process conditions are as follows: the reaction time is 50 minutes, the reaction temperature is 0-25°C, and the complexing agent is glycerin, Ethylene glycol and potassium sodium tartrate are used in combination, and the additive Fe2+ (FeSO4) is added to the plating solution;

[0050] The preparation method of the copper plat...

Embodiment 3

[0054] The preparation method of copper plating on the surface of carbon nanotubes in this embodiment adopts Cu2+ as the source of elemental copper, and the reducing agent is Zn; its main reagents are CuSO4 5H2O, Zn powder, glycerol, ethylene glycol, potassium sodium tartrate, FeSO4 ·7H2O, HNO3; the concentration requirement of Cu2SO4·5H2O is 7.0g / l, the concentration requirement of glycerol is 140ml / l, the concentration requirement of ethylene glycol is 95ml / l, the concentration requirement of potassium sodium tartrate is 9.0g / l l, the concentration of FeSO4 7H2O is required to be 4.0g / l, and the concentration of zinc powder is required to be 1.90g / l; the process conditions are as follows: the reaction time is 70 minutes, the reaction temperature is 0-25°C, and the complexing agent is glycerin, Ethylene glycol and potassium sodium tartrate are used in combination, and the additive Fe2+ (FeSO4) is added to the plating solution;

[0055] The preparation method of the copper pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com