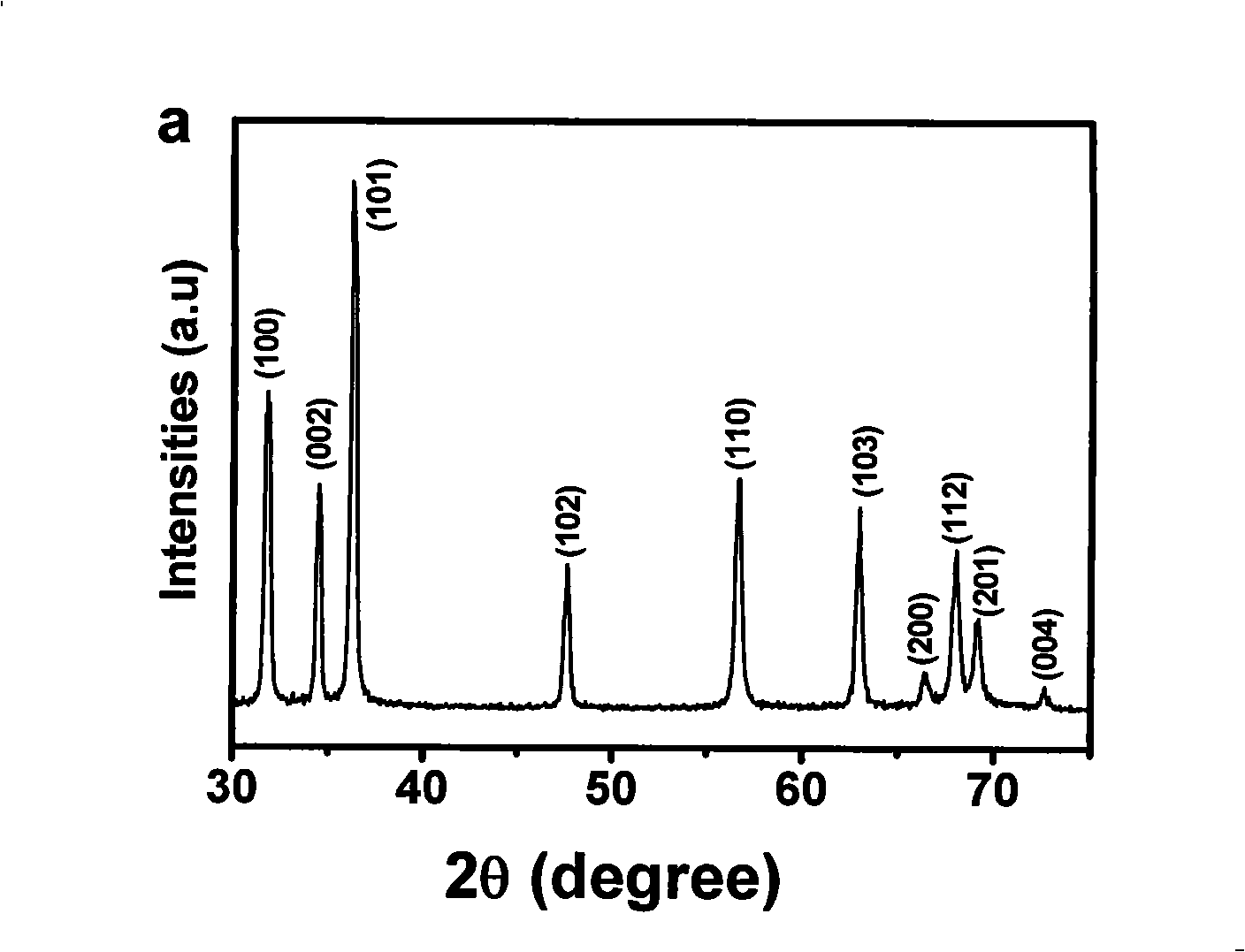

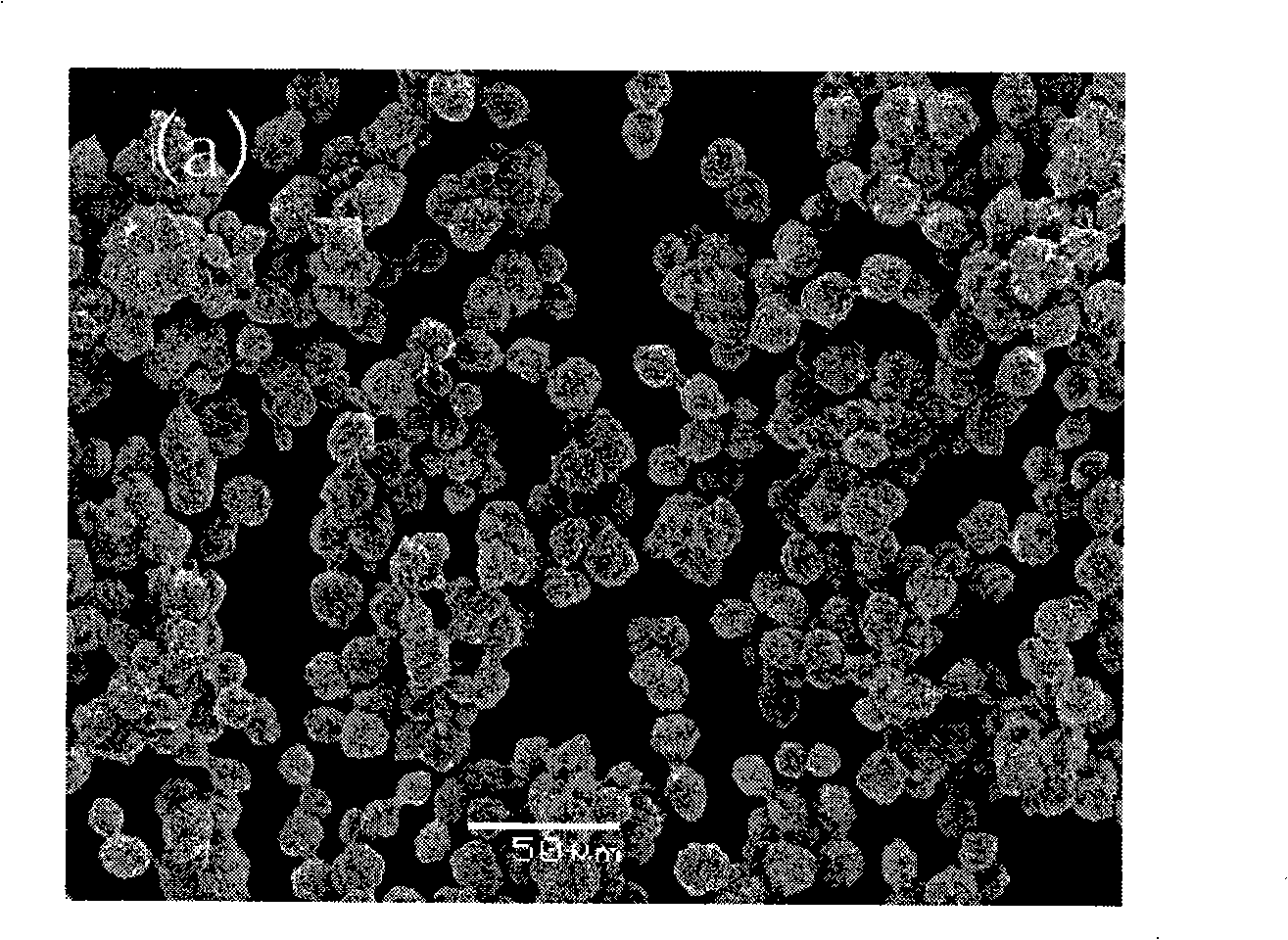

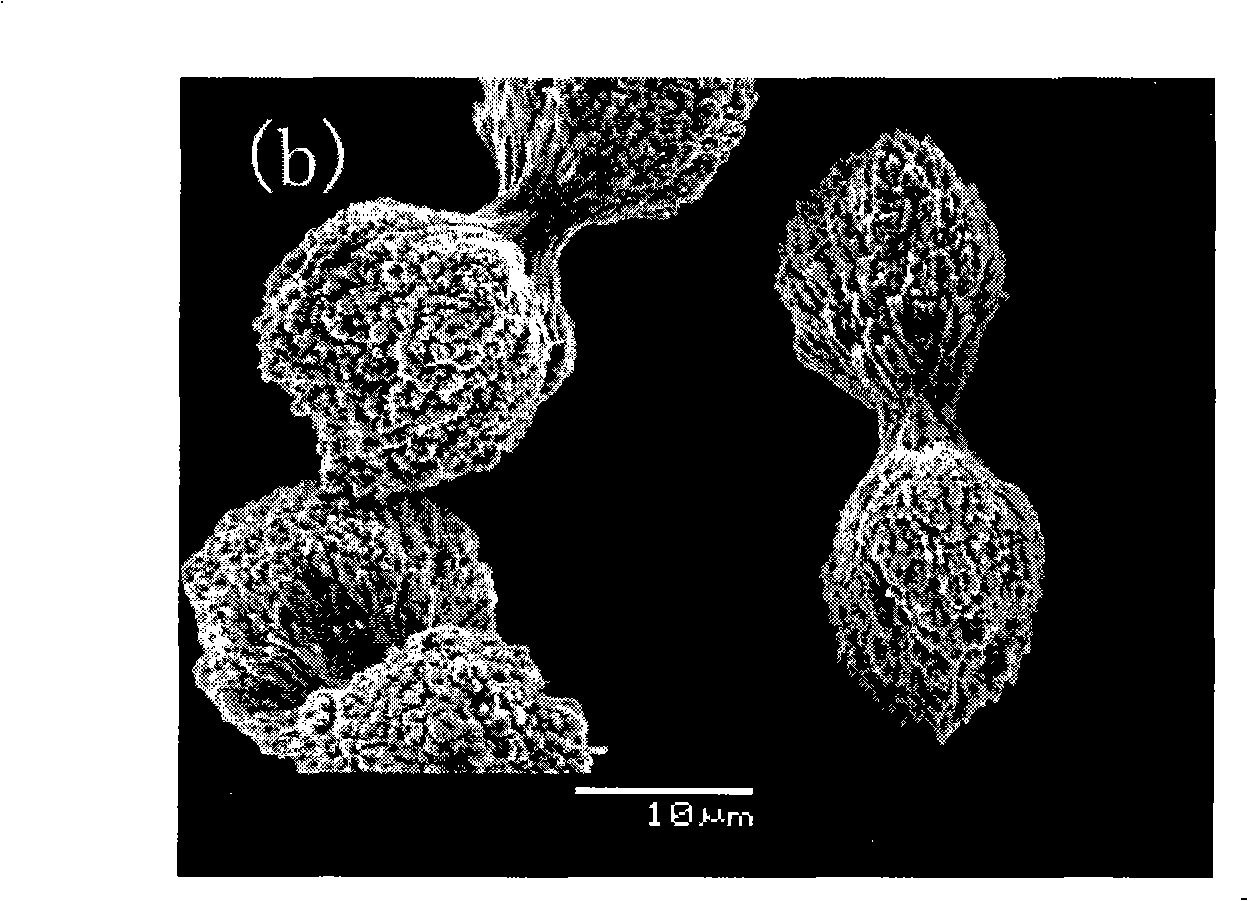

Dumb-bell-shaped ZnO micrometre material and method for preparing same

A dumbbell-shaped, micron-structured technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve problems such as not seeing, and achieve highly repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a) In a clean glass beaker, pour 20ml of deionized water and 1.5g of Zn(CH 3 COO) 2 2H 2 O dissolved in it;

[0025] b) Slowly add a certain amount of ammonia water to the glassware, stir constantly with a magnetic stirrer, and maintain the pH of the solution at 8.5;

[0026] c) Seal the glassware with a film, put it into an oven and heat it for 13 hours at a temperature of 55°C;

[0027] d) Remove the film and continue heating at a temperature of 32°C until the glassware is dried;

[0028] e) scrape off the white precipitate left on the bottom of the glass vessel, and take out the sample to obtain the dumbbell-shaped ZnO micron material.

Embodiment 2

[0030] a) In a clean glass beaker, pour 20ml of deionized water and 1.5g of Zn(CH 3 COO) 2 2H 2 O dissolved in it;

[0031] b) Slowly add a certain amount of ammonia water to the glassware, stir continuously with a magnetic stirrer, and maintain the pH of the solution at 8.6;

[0032] c) Seal the glassware with a film, put it into an oven and heat it for 12 hours at a temperature of 50°C;

[0033] d) Remove the film and continue heating at a temperature of 32°C until the glassware is dried;

[0034] e) scrape off the white precipitate left on the bottom of the glass vessel, and take out the sample to obtain the dumbbell-shaped ZnO micron material.

Embodiment 3

[0036] a) In a clean glass beaker, pour 20ml of deionized water and 1.5g of Zn(CH 3 COO) 2 2H 2 O dissolved in it;

[0037] b) Slowly add a certain amount of ammonia water to the glassware, stir continuously with a magnetic stirrer, and maintain the pH of the solution at 8.6;

[0038] c) Seal the glassware with a film, put it into an oven and heat it for 13 hours at a temperature of 53°C;

[0039] d) Remove the film and continue heating at a temperature of 31° C. until the glassware is dried;

[0040] e) scrape off the white precipitate left on the bottom of the glass vessel, and take out the sample to obtain the dumbbell-shaped ZnO micron material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap