Method for controlling band steel continuous production units utilizing coordinating control module

A technology of coordinated control and strip steel, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of surface scratches on the strip steel, poor dynamic response performance of operation commands, etc., to avoid scratches and ensure line speed, ensuring consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

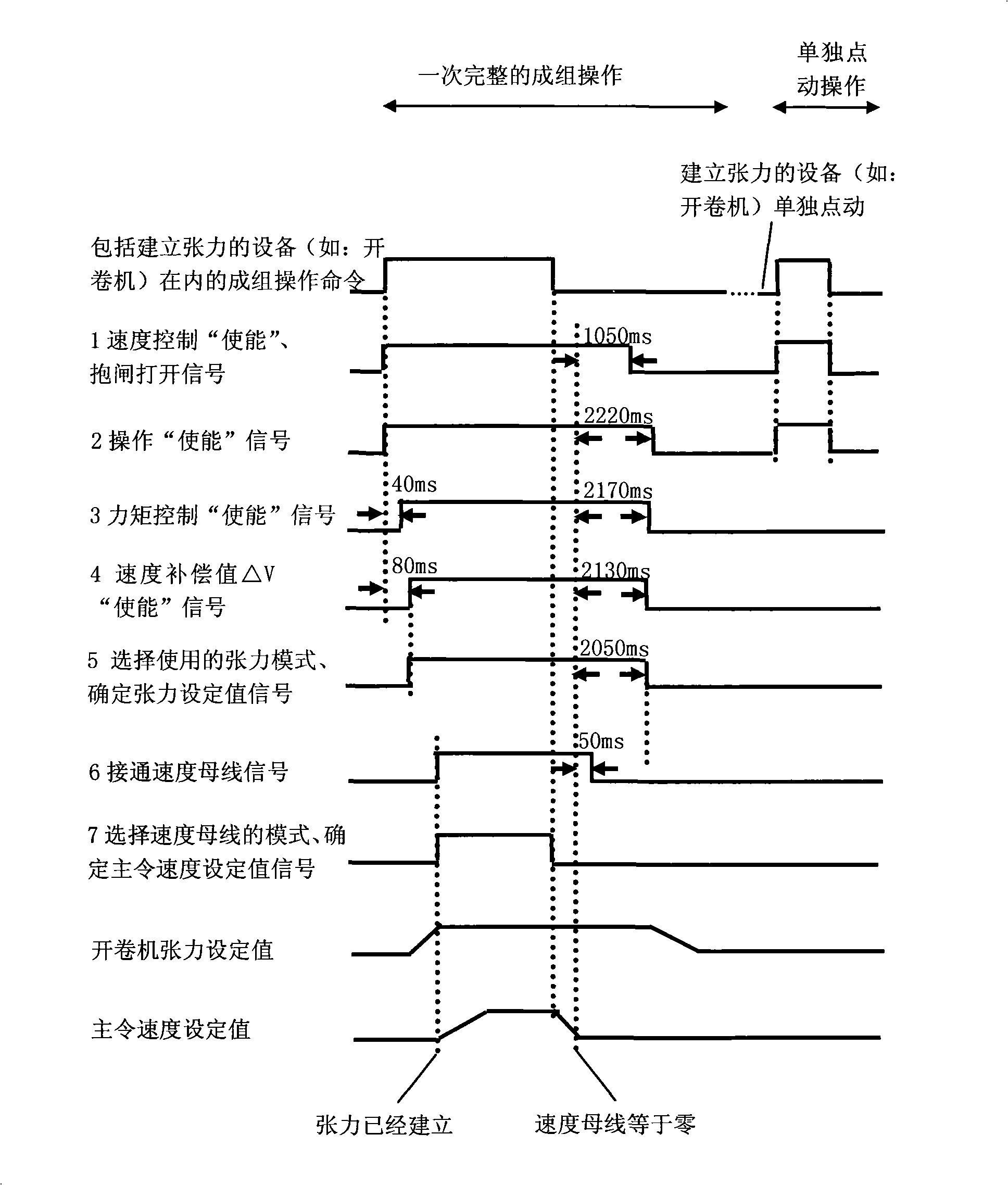

[0067] see figure 2 , figure 2 It is a schematic diagram of the timing relationship between the control signals in the control method of the equipment for establishing tension according to the present invention, and there are differences according to the operation mode (a complete group operation or a single jog operation), and the specific description is as follows:

[0068] The preferred control method of the present invention to the equipment that establishes tension in a complete group operation is:

[0069] The speed control "enable" and the brake opening signal 1 are turned on simultaneously with the group operation command being turned on, and it is turned off with a delay of 1050ms after the group operation command is turned off and the main command speed drops to zero;

[0070] The operation "enable" signal 2 is turned on simultaneously with the group operation command being turned on, and it is turned off with a delay of 2220ms after the group operation command is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com