Method for synthesizing alpha-Fe2O3 nano-particle with controllable shape size

A nanoparticle and size technology, applied in the field of α-Fe2O3 preparation, can solve the problems of high cost, narrow size distribution, complex process, etc., and achieve the effects of low cost, good dispersibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 0.541g FeCl respectively 3 ·6H 2 O, 0.5852g lysine, dissolves with 100ml deionized water, forms clarification solution through magnetic stirring, then transfers in the reactor, seals. The reaction kettle was placed in an oven at 120°C for 1 day, and then naturally cooled to room temperature. The product was centrifuged, washed twice with water and once with ethanol, and dried in an oven at 50°C for 6 hours to finally obtain the product.

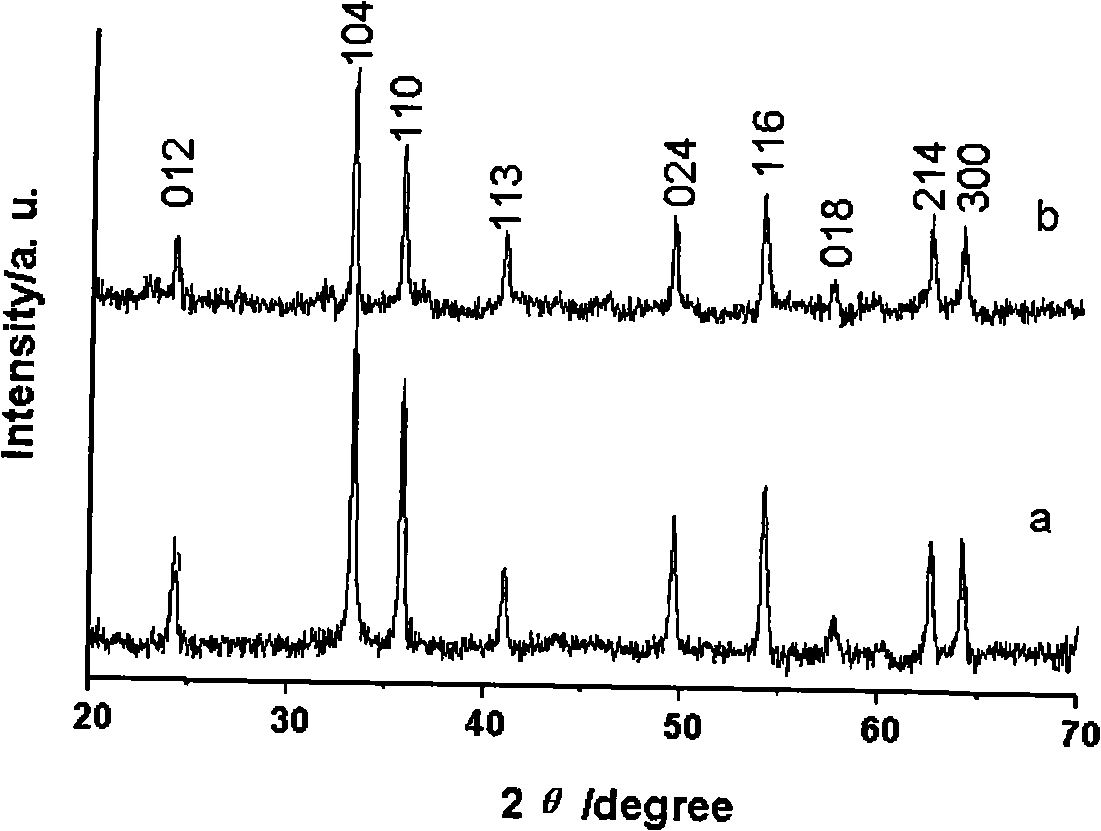

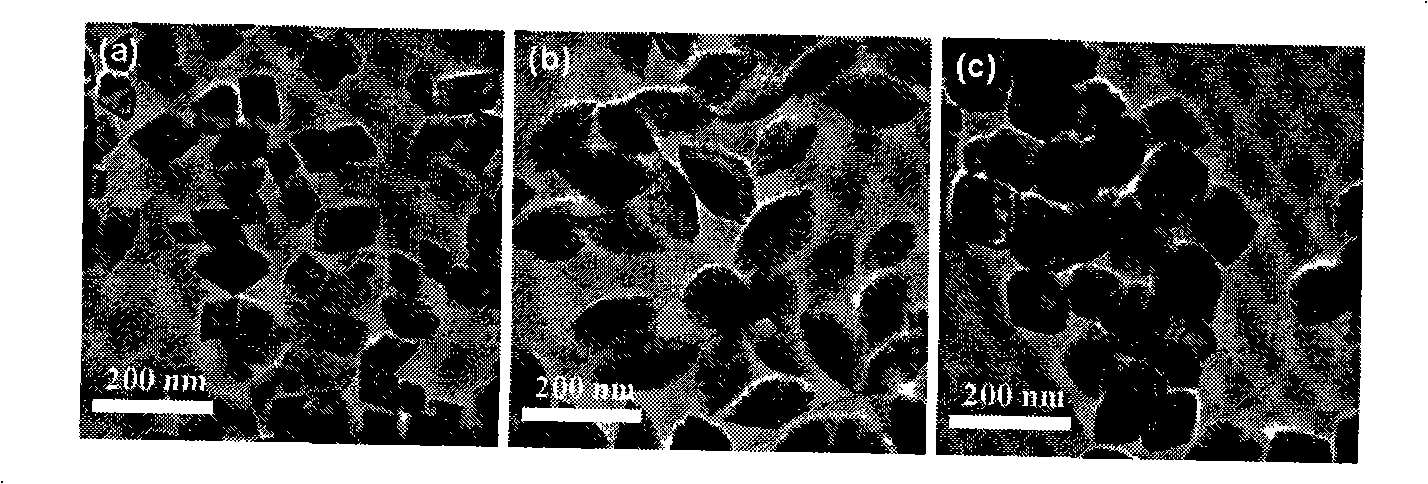

[0019] figure 1 (a) α-Fe prepared for this example 2 o 3 Nanoparticle XRD spectrum, its characteristic peaks are related to α-Fe 2 o 3 The standard peaks are consistent. figure 2 (a) is the α-Fe prepared by the present embodiment 2 o 3 TEM images of nanoparticles. It can be seen that α-Fe 2 o 3 The nanoparticles have a rhombohedral structure with a very uniform size and a side length of about 65nm.

Embodiment 2

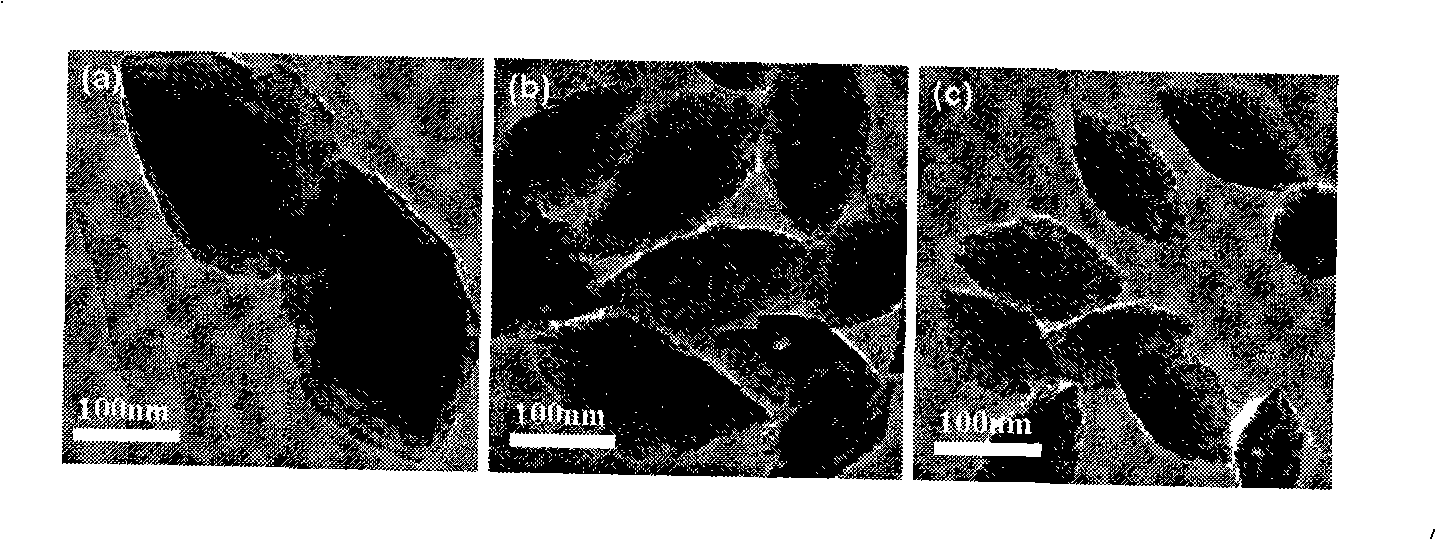

[0021] Weigh 0.541g FeCl respectively 3 ·6H 2 0.0.1322g asparagine, other conditions are with embodiment 1, and the XRD spectrum of gained product is as figure 1 Shown in (b), its characteristic peak is consistent with embodiment 1. figure 2 (b) and image 3 (c) is the α-Fe prepared by the present embodiment 2 o 3 TEM images of nanoparticles. It can be seen from the figure that α-Fe 2 o 3 It is leaf-shaped, with a narrow size distribution, the long axis is about 150nm, and the short axis is about 90nm.

Embodiment 3

[0023] Weigh 0.541g FeCl respectively 3 ·6H 2 0.0.2984g methionine, other conditions are with embodiment 1, and the TEM figure of gained product is as follows figure 2 As shown in (c), α-Fe 2 o 3 The nanoparticles have a cube-like structure with an aspect ratio of about 1, uniform size, and a side length of 80 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com