Rubber composition for coating tire cord

A technology of rubber composition and tire cord, which is applied in the field of tire cord, can solve the problems of reduced rubber breaking strength, insufficient adhesion, etc., and achieve the effect of increasing breaking strength, improving wet and hot adhesion, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11 and comparative example 1-10

[0043] (Material)

[0044] NR: TSR20 (made in Thailand)

[0045] BR1250H: Polybutadiene rubber produced by Zeon Co., Ltd. (using lithium as an initiator to polymerize)

[0046] Carbon black N330: Carbon black N330 produced by Showa CABOT Co., Ltd.

[0047] Carbon black N326: carbon black N326 produced by Showa CABOT Co., Ltd.

[0048] Silica Z115G: Z115Gr produced by Rhodia

[0049] Silane coupling agent: Si69 produced by Deggusa

[0050] Cobalt stearate: cobalt stearate produced by Dainippon Ink Chemical Industry Co., Ltd.

[0051] Oil-treated insoluble sulfur: Crystex manufactured by Flexsys (contains 80% of insoluble sulfur and 20% of oil, and the mixing amount of the whole oil-treated insoluble sulfur containing oil is recorded in the table)

[0052] Vulcanization accelerator DCBS: Accel DZ-G (N, N-dicyclohexylbenzothiazole sulfenamide) produced by Kawaguchi Chemical Industry Co., Ltd.

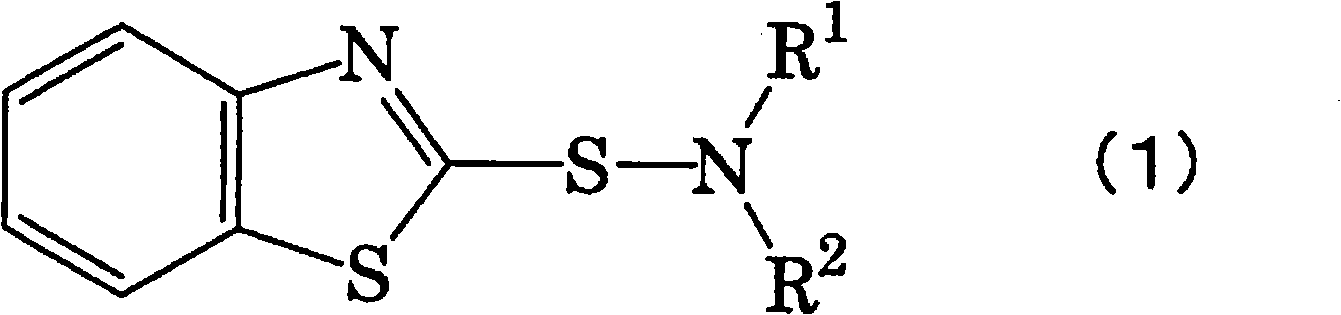

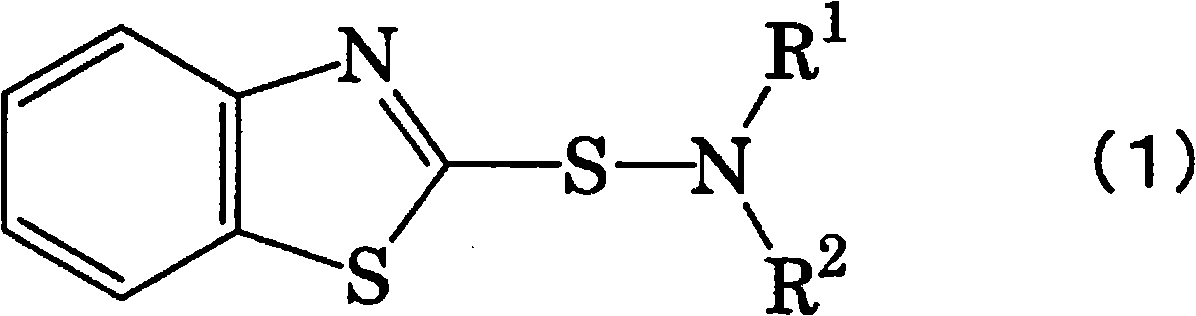

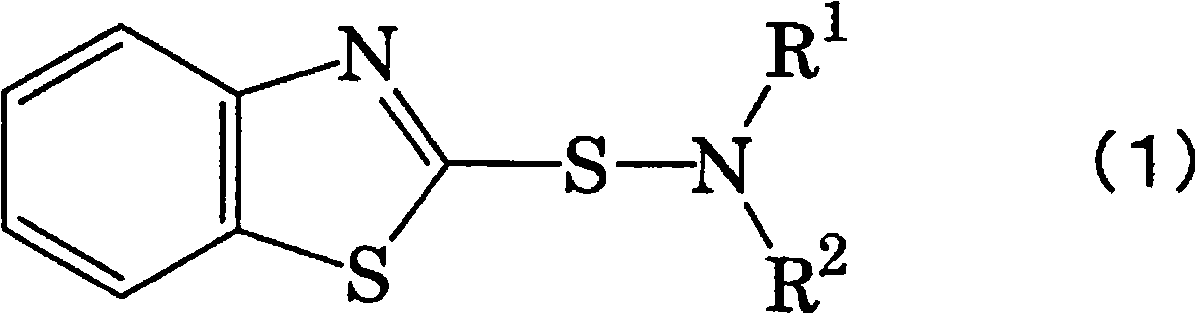

[0053] Vulcanization accelerator BEHZ: BEHZ (N,N-bis(2-ethylhexyl)benzothiazole ...

Embodiment 12~21 and comparative example 11~19

[0081] (Production method)

[0082] Each chemical in the mixing content shown in Table 3 and Table 4 except sulfur and vulcanization accelerator was mixed in a Banbury mixer, and oil-treated insoluble sulfur and sulfur were added to the resulting mixed product. Various vulcanization accelerators are mixed in an open mill to obtain an unvulcanized rubber composition. This unvulcanized rubber composition was vulcanized under pressure at 150° C. for 30 minutes to obtain a vulcanized rubber sample. Regarding aromatic oil, anti-aging agent and zinc oxide, although there is no record in Table 3 and Table 4, they were mixed in all Examples and Comparative Examples with 2 parts by weight, 1 part by weight, and 10 parts by weight, vulcanization accelerator and DCBS Equimolar amounts were mixed.

[0083] The compositions obtained in Examples 12 to 21 and Comparative Examples 11 to 19 were evaluated in the same manner as the above test method. The respective test results are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com