Method of forming a self aligned copper capping layer

A technology of barrier layer and interconnection layer, which is applied in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Therefore, here is proposed a process for forming a self-aligned Cu alloy capping layer on metal interconnects with improved adhesion properties and resistance to electromigration and stress-induced voids near the top of the interconnect lines. Cavity formation is inhibited. This can be achieved by forming an intermetallic compound, such as a copper alloy compound (eg, CuAlN), in close proximity to the top of the interconnect. Thus, the indiffusion of aluminum into copper can be controlled.

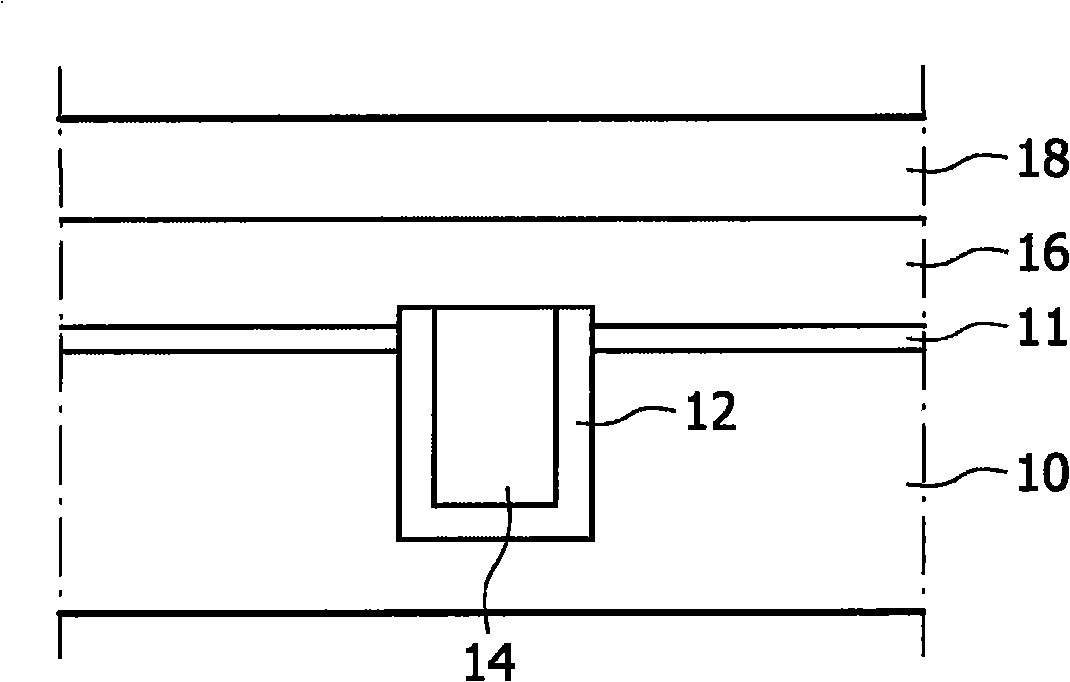

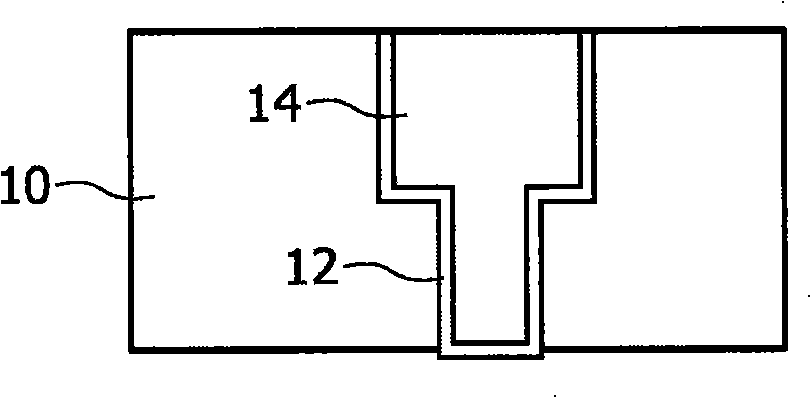

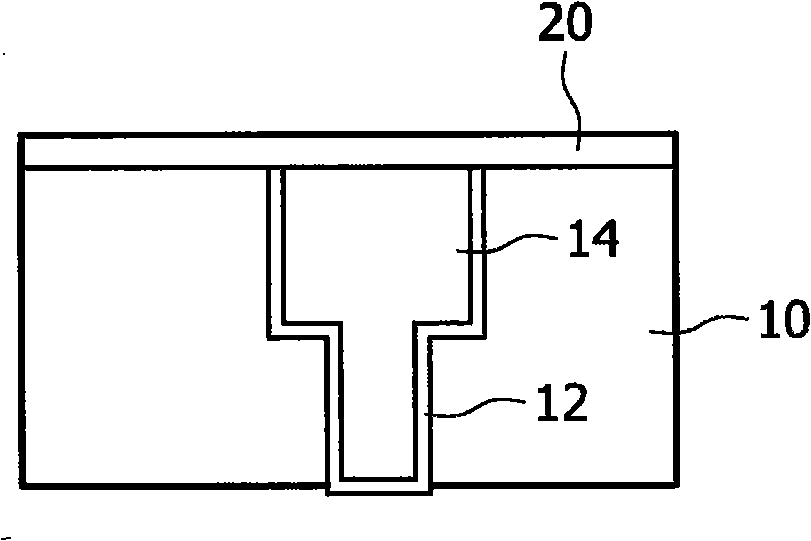

[0036] Starting from the structure after the chemical mechanical polishing step, and referring to the attached Figure 3a and Figure 4a , copper interconnects 14 are embedded within metal-in-dielectric layer 10 with barrier layer 12 therebetween. In a first example embodiment of the present invention, a thin metallic Al (or Mg, B, Zn, etc.) Figure 3b shown. Next, a reactive annealing process is performed in an ammonia environment, or in a nitrogen, oxygen, or carbon-containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com